Circular stockyard scraper chain tensioning hydraulic system

A technology of scraper chain and circular stock yard, which is applied in the direction of loading/unloading, conveyor, transportation and packaging, etc. It can solve the problem that the chain is too loose or too tight, which affects the normal operation of the equipment, and the chain has a large impact on its own weight and working load, etc. problem, to achieve the effect of changing the pressure-holding mechanism, facilitating real-time signal acquisition and control, and simplifying the pressure-holding and shock-absorbing branch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

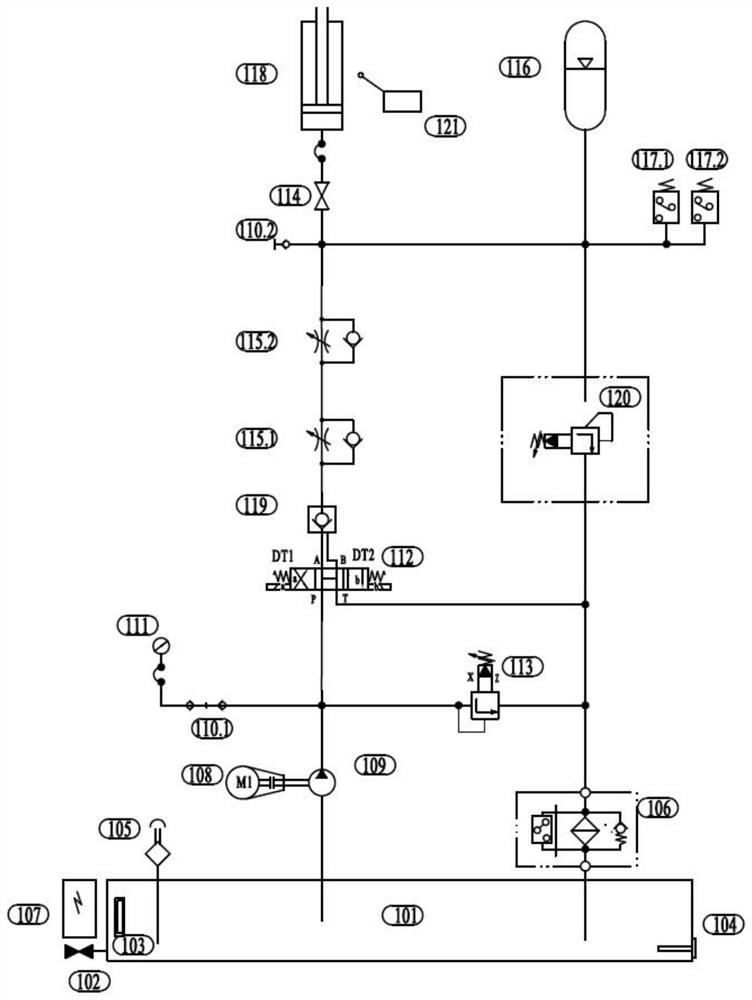

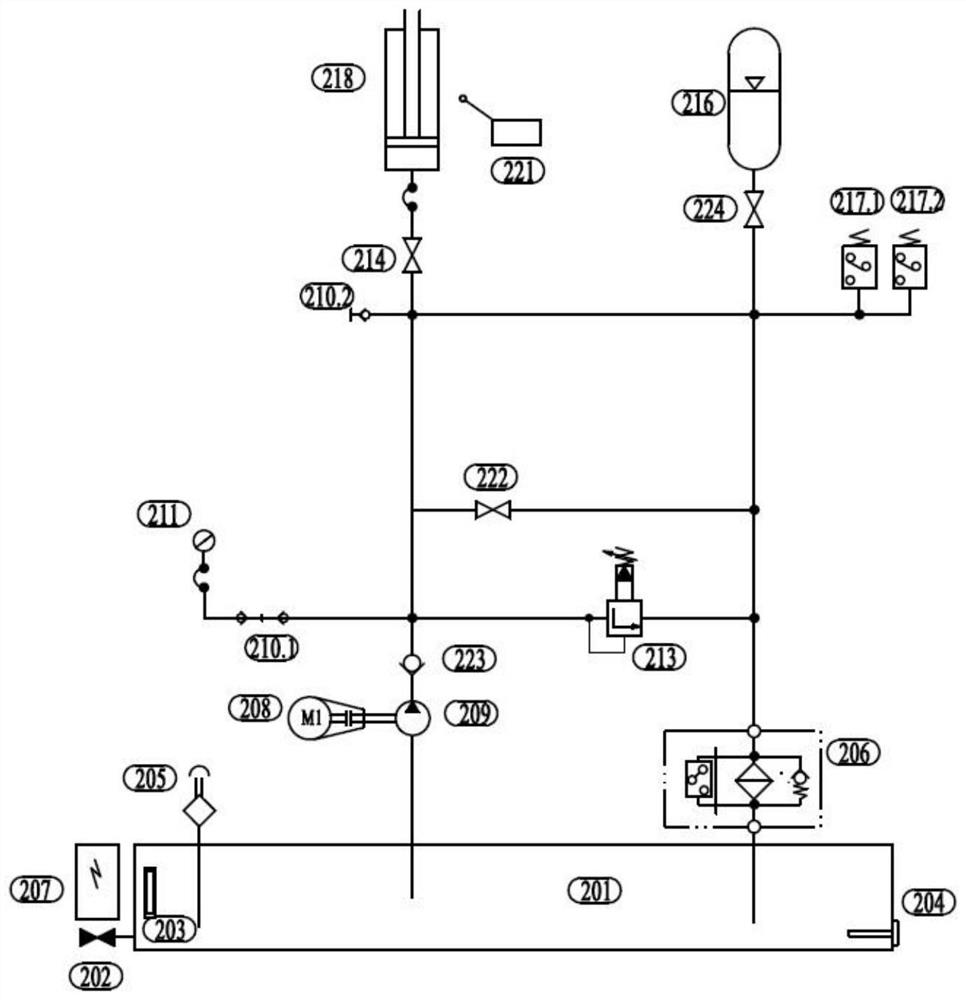

[0022] The core of the present invention is to provide a circular stockyard scraper chain tensioning hydraulic system, by simplifying the composition of the control valve parts of the main oil circuit, changing the pressure maintaining mechanism of the system, changing the purpose of the accumulator circuit, and overcoming the original The disadvantages of the system reduce the manufacturing cost; simplify the system control point, which is more conducive to the realization of intelligent control; enhance the system pressure maintaining and shock absorption capacity, and improve the service life of hydraulic components.

[0023] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com