Multipurpose electromagnetic valve and water purifier system consisting of same

A technology of solenoid valves and valve seats, applied in multi-way valves, valve devices, mechanical equipment, etc., can solve the problems of water resource waste, etc., and achieve the effects of prolonging flushing time, improving pressure holding effect, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

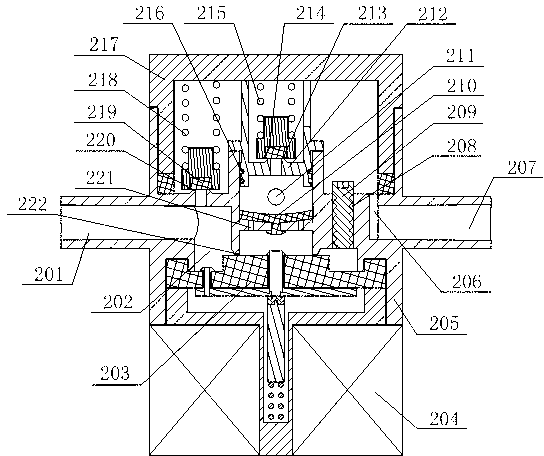

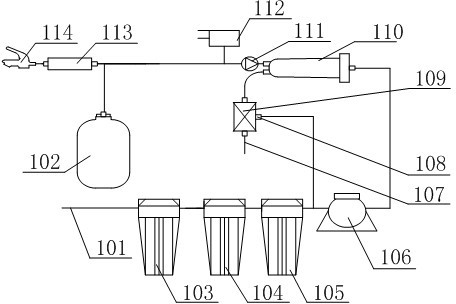

[0018] Such as figure 1 As shown, the multi-purpose solenoid valve includes a valve seat 205 and a valve seat cover 217 sealingly connected with the valve seat 205. The valve seat 205 is provided with a flushing and drainage inlet 201, a concentrated water discharge port 207, a flushing return water port 108, and a concentrated water discharge port. 207 is connected with the concentrated water discharge pipe 107, and the valve seat 205 is provided with a water inlet chamber 202 connected to the flushing and drainage inlet 201 and a flushing backflow channel 211 connected to the flushing backflow water port 108, and the valve seat 205 and the valve seat cover 217 constitute There is a concentrated water outlet chamber, and the concentrated water outlet chamber is connected to the concentrated water outlet 207 through the concentrated water flow channel 206 formed by the valve seat 205 . Both the flushing backflow channel 211 and the concentrated water outlet chamber are connect...

Embodiment 2

[0021]This embodiment adds the following structure on the basis of Embodiment 1: the valve seat 205 forms a pressure relief sealing port 220 connected to the water inlet chamber 202 and the concentrated water outlet chamber, and the concentrated water outlet chamber is provided with a pressure relief spring 2 218 and pressure relief seal seat 2 219, pressure relief seal seat 2 219 seals pressure relief seal water port 2 220, the two ends of pressure relief spring 2 218 act on valve seat cover 217 inner top and pressure relief seal seat 2 219 respectively, release The pressure spring 2 218 and the pressure relief seal 2 219 constitute the pressure relief assembly 2 that controls the switching of the water path between the water inlet chamber 202 and the concentrated water outlet chamber in on and off states. The valve seat 205 is connected with a choke rod 209, and a choke channel 208 connecting the water inlet chamber 202 and the concentrated water outlet chamber is formed betw...

Embodiment 3

[0023] This embodiment adds the following structure on the basis of Embodiment 1 or Embodiment 2: the valve seat 205 is connected with a pressure relief water sealing plate 212, and a sealing ring 216 is arranged between the valve seat 205 and the pressure relief water sealing plate 212. The pressure sealing water plate 212 is formed with a pressure relief sealing water port 213 connecting the flushing return flow channel 211 and the concentrated water outlet chamber. The concentrated water outlet chamber is provided with a pressure relief seal seat 214 and a pressure relief spring 1 215. Seat one 215 seals the pressure relief sealing water port one 213, and the two ends of the pressure relief spring one 215 respectively act on the inner top of the valve seat cover 217 and the pressure relief seal seat one 214, and the pressure relief seal seat one 214 and the pressure relief spring one 215 form a control valve. Pressure relief component 1 that switches between the water path b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com