Pd<x>Pt<(50-x)>Bi<50> ternary alloy nanoparticles as well as preparation method and application thereof

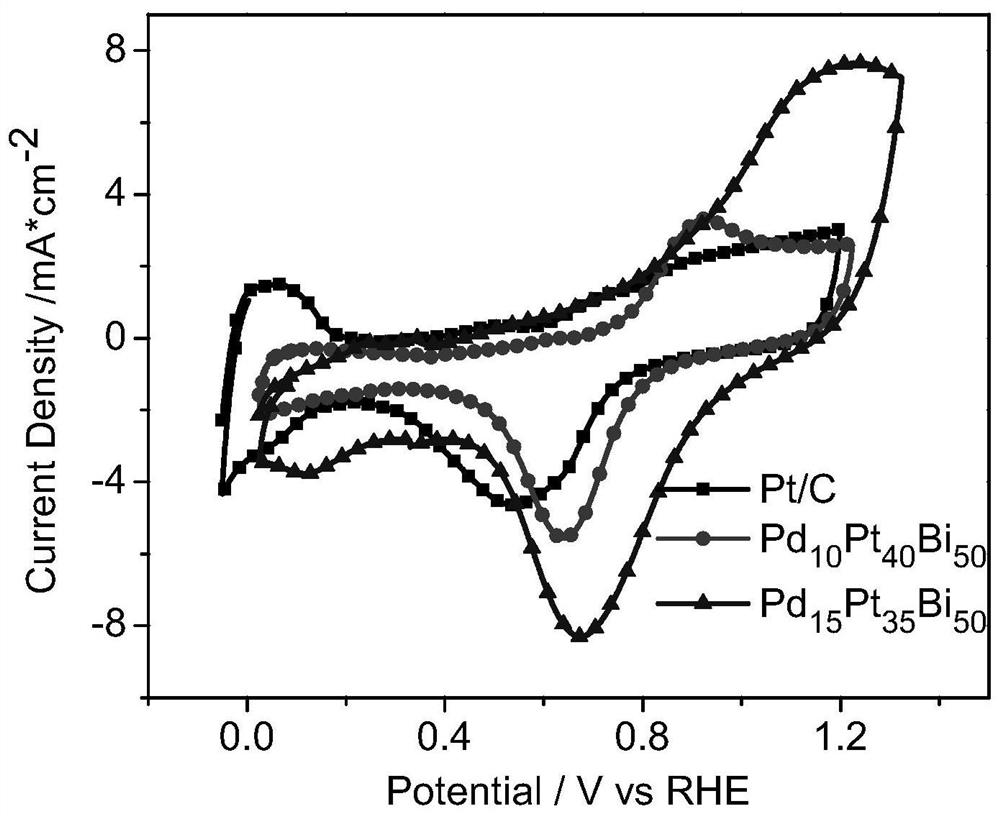

A ternary alloy and nanoparticle technology, applied in the field of alloy materials and electrochemistry, can solve the problems of ORR activity and stability need to be improved, and achieve the effect of being conducive to large-scale preparation, simple method, and excellent ORR test catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

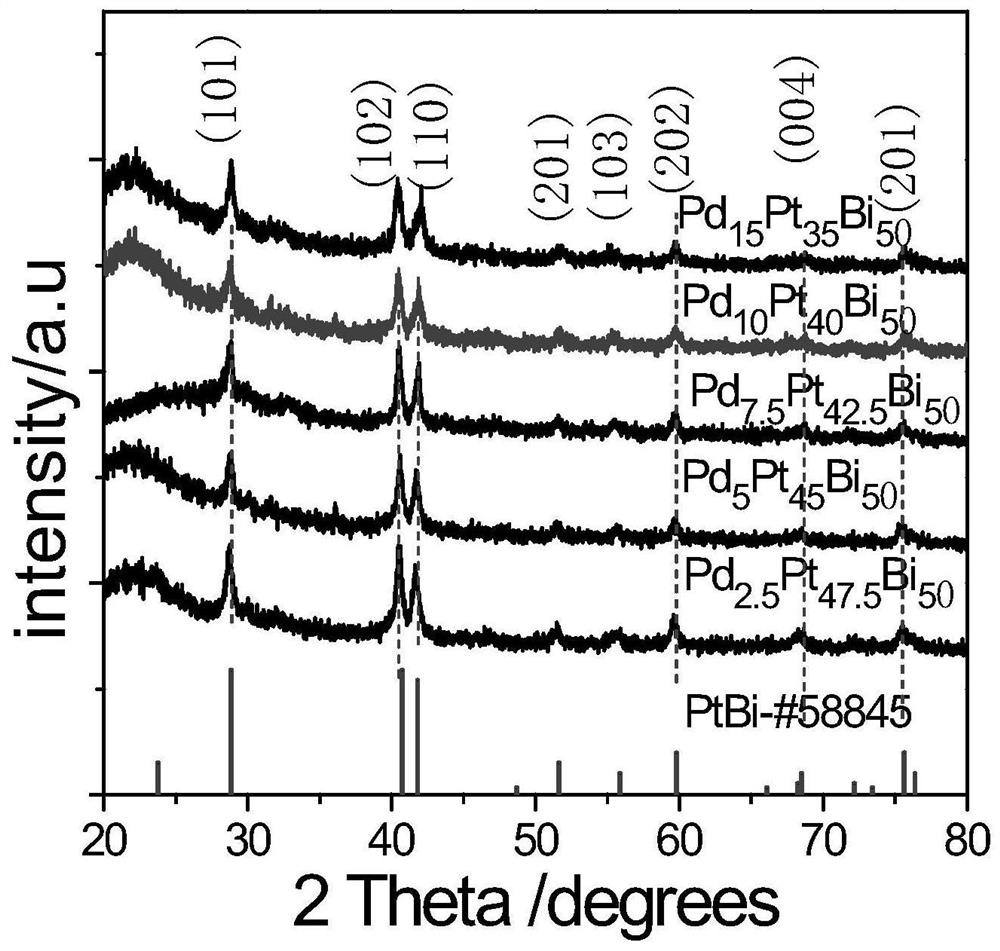

[0054] A single-phase Pd with a hexagonal close-packed structure in this embodiment 15 Pt 35 Bi 50 A method for synthesizing ternary alloy nanoparticles, the method comprising the steps of:

[0055] (1) Put 10-15mL of liquid octadecene solvent with 90% purity and 5-10mL of oleylamine solvent with 90% purity into a four-necked glass flask to obtain a mixed solvent; After passing high-purity nitrogen gas for 30 minutes, pour 0.285mmol of bismuth acetate, 1.5mmol of 1,2-hexadecanediol, and 1.1g of cetyltrimethylammonium bromide into the mixed solvent and heat to 80°C to dissolve , while maintaining mechanical stirring at a speed of 1000 rpm. After the bismuth acetate is completely dissolved, add 1 to 3 mL of oleic acid with a purity of 90% to the above-mentioned four-neck glass flask, stir for 5 minutes and mix well, and then mix the resulting mixture for 1 Continue heating to 120°C to 130°C for 1 hour, and after the reaction is completed, a partially reduced Bi precursor is o...

Embodiment 2

[0058] A single-phase Pd with a hexagonal close-packed structure in this embodiment 5 Pt 45 Bi 50 A method for synthesizing ternary alloy nanoparticles, the method comprising the steps of:

[0059] (1) Put 10-15mL of liquid octadecene solvent with 90% purity and 5-10mL of oleylamine solvent with 90% purity into a four-necked glass flask to obtain a mixed solvent; After passing high-purity nitrogen gas for 30 minutes, pour 0.222mmol of bismuth acetate, 1.5mmol of 1,2-hexadecanediol, and 1.1g of cetyltrimethylammonium bromide into the mixed solvent and heat to 80°C to dissolve , while maintaining mechanical stirring at a speed of 1000 rpm; after the bismuth acetate is completely dissolved, add 1 to 3 mL of oleic acid with a purity of 90% to the above-mentioned four-necked glass flask, stir for 5 minutes and mix well, and then mix the resulting mixture for 1 Continue heating to 130°C to 140°C for 1 hour, and after the reaction is completed, a partially reduced Bi precursor is ...

Embodiment 3

[0062] A single-phase Pd with a hexagonal close-packed structure in this embodiment 10 Pt 40 Bi 50 A method for synthesizing ternary alloy nanoparticles, the method comprising the steps of:

[0063] (1) Put 10-15mL of liquid octadecene solvent with 90% purity and 5-10mL of oleylamine solvent with 90% purity into a four-necked glass flask to obtain a mixed solvent; After passing high-purity nitrogen gas for 30 minutes, sequentially pour 0.205 mmol of bismuth acetate, 1.5 mmol of 1,2 hexadecanediol, and 1.1 g of cetyltrimethylammonium bromide into the mixed solvent and heat to 80°C to dissolve , while maintaining mechanical stirring at a speed of 1000 rpm. After the bismuth acetate is completely dissolved, add 1 to 3 mL of oleic acid with a purity of 90% to the above-mentioned four-neck glass flask, stir for 5 minutes and mix well, and then mix the resulting mixture for 1 Continue heating to 120°C to 130°C for 1 hour, and after the reaction is completed, a partially reduced B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com