Reverse osmosis cleaning agent for seawater desalination equipment as well as preparation method and use method thereof

A technology of reverse osmosis and cleaning agent, applied in chemical instruments and methods, reverse osmosis, seawater treatment, etc., can solve the problems of easy retention, damage to reverse osmosis membrane, and difficult removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

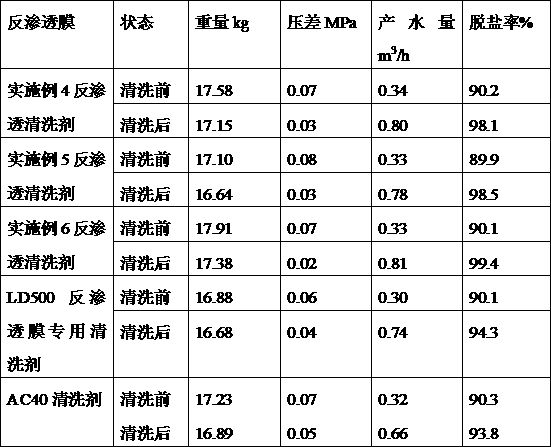

Examples

preparation example Construction

[0040] The present invention includes a preparation method of a reverse osmosis cleaning agent for seawater desalination equipment, comprising the following steps:

[0041] In parts by weight, add 1 to 3 parts of citric acid, 1.5 to 2.5 parts of formic acid and 2 to 6 parts of trisodium nitrilotriacetate to 80 to 160 parts of deionized water, add 0.5 to 1.5 parts of hydrochloric acid under stirring conditions, and stir for at least 30 Minutes to get acid A agent;

[0042] Add 2~4 parts of ethylenediamine tetraacetate, 0.5~0.8 parts of polyethyleneimine, 1.2~2 parts of alcohol amine organic base, and non-ionic surface of fatty alcohol polyoxyethylene ether to 100~140 parts of deionized water. 2~4 parts of active agent, 1.5~2.5 parts of membrane repair agent and 0.6~1.4 parts of β-cyclodextrin, add 0.5~2 parts of inorganic base under stirring condition, and stir for at least 30 minutes for multifunctional agent B;

[0043]Wherein, the inorganic base is sodium hydroxide or potas...

Embodiment 1

[0048] A formula of reverse osmosis cleaning agent for seawater desalination equipment, including acid A agent and multifunctional B agent;

[0049] The acid A agent is made up of the following materials: citric acid 10kg, hydrochloric acid 5kg, formic acid 15kg, trisodium nitrilotriacetate 20kg and deionized water 800kg;

[0050] The multifunctional agent B is composed of the following materials: 5kg of sodium hydroxide, 20kg of disodium edetate, 5kg of polyethyleneimine, 12kg of diethanolamine, 20kg of polyoxyethylene lauryl alcohol, and 15kg of succinic dialdehyde , β-cyclodextrin 6kg and deionized water 1000kg;

Embodiment 2

[0052] A formula of reverse osmosis cleaning agent for seawater desalination equipment, including acid A agent and multifunctional B agent;

[0053] The acid A agent is made up of the following materials: 30kg of citric acid, 15kg of hydrochloric acid, 25kg of formic acid, 60kg of trisodium nitrilotriacetate and 1600kg of deionized water;

[0054] The multifunctional agent B is composed of the following materials: 20kg of potassium hydroxide, 40kg of tetrasodium edetate, 8kg of polyethyleneimine, 20kg of ethanolamine, 40kg of cetyl alcohol polyoxyethylene ether, 25kg of glutaraldehyde, β-cyclodextrin 14kg and deionized water 1400kg;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com