System for resource utilization of waste blades in rotary kiln and working method of system

A rotary kiln and recycling technology, applied in the system field of recycling waste blades, can solve the problems of lack of mature technology, waste of resources, difficult degradation of thermosetting composite materials, etc., and achieve high utilization rate and large processing capacity. , the effect of good environmental protection and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

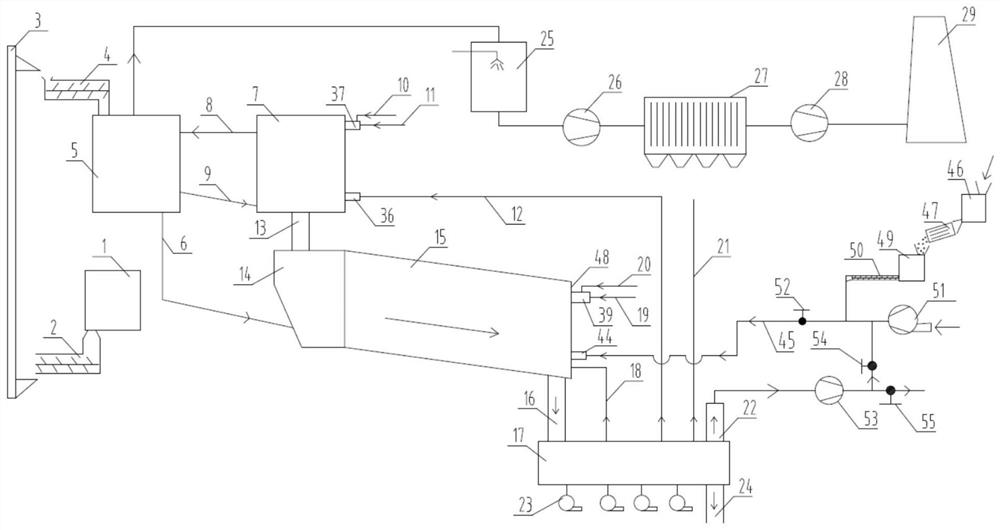

[0039] Such as figure 1 , In the system for recycling waste blades in the rotary kiln of the present invention, raw materials such as clay and limestone are crushed and transported to the homogenizing bin 1 in a certain proportion for homogenization and mixing treatment to form raw materials. There is a discharge port at the bottom of the homogenizing bin 1, which is transported to the bucket elevator 3 through the first auger 2, and is lifted to a certain height of the suspension preheater 5 by the bucket elevator 3. After the bucket elevator 3 is unloaded, it is also used The second auger 4 transports the raw material and sends it into the suspension preheater 5 .

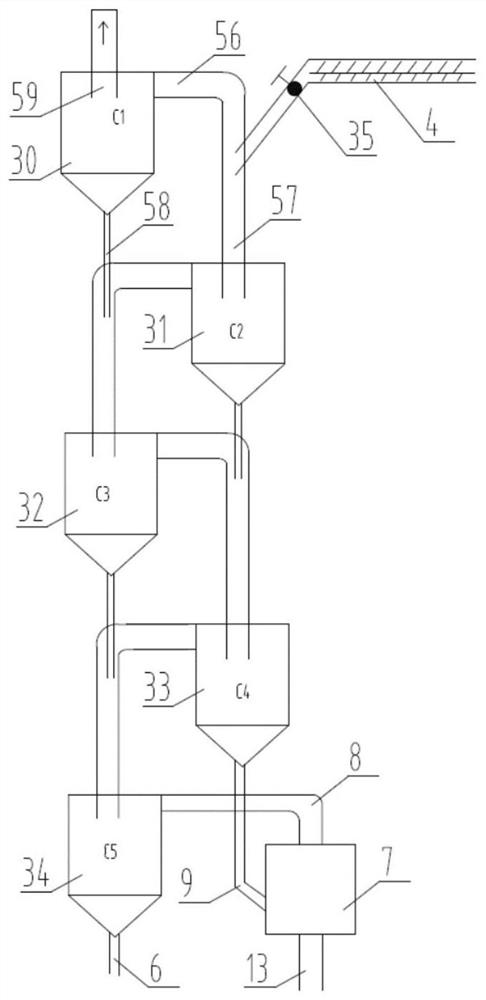

[0040] Such as figure 2 As shown, in one embodiment of the present invention, the suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com