Microcrystalline glass solder and preparation method thereof, and method for connecting aluminum oxide ceramics

A technology of alumina ceramics and glass ceramics, which is applied in the field of glass ceramics solder and its preparation, and connection of alumina ceramics, which can solve the problem of affecting the mechanical properties of joints, the quality of alumina ceramic connections, increasing the difficulty of ceramic connection processes, and poor matching of thermal expansion coefficients and other problems, to achieve the effect of improving the connection quality, matching the thermal expansion coefficient, and reducing the welding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

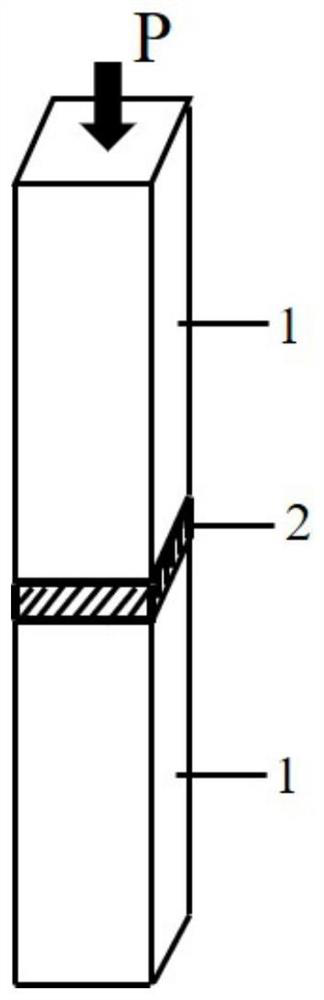

Image

Examples

Embodiment 1

[0030] 1. A glass-ceramic solder in the present embodiment, its chemical composition is CaO 15wt%, Al 2 o 3 15 wt%, SiO 2 55wt%, ZnO 5wt%, B 2 o 3 10 wt%; the coefficient of thermal expansion of the glass-ceramic solder between 25 and 700°C is 6.2×10 -6 / °C.

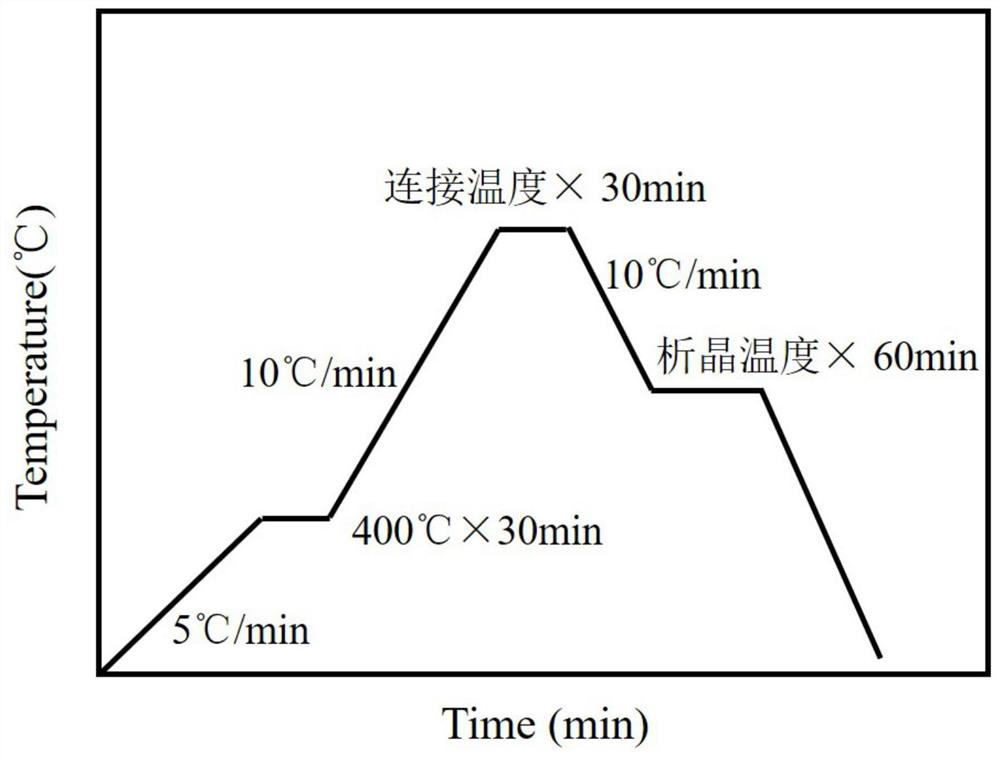

[0031] 2. The preparation method of the glass-ceramic solder of the present embodiment, the following steps are as follows:

[0032] (1) Ball milling mixture

[0033] According to the above chemical composition ratio, with CaCO 3 、Al 2 o 3 , SiO 2 , ZnO, H 3 BO 3 After weighing the raw materials, in a polytetrafluoroethylene ball mill tank, according to the mass ratio of raw materials: grinding balls: deionized water = 1:2:1, wet ball milling at a speed of 300r / min for 5 hours to obtain a mixed material;

[0034] (2) Melting and quenching

[0035] The above mixed material was dried at 100°C for 10 hours, ground and passed through a 200-mesh sieve, then melted at 1450°C for 1 hour, and then poured the melted ...

Embodiment 2

[0044] This embodiment differs from Embodiment 1 in that:

[0045] The chemical composition of glass-ceramic solder is CaO 10wt%, Al 2 o 3 20 wt%, SiO 2 55wt%, ZnO10wt%, B 2 o 3 5 wt%; the thermal expansion coefficient of the glass-ceramic solder between 25 and 700°C is 6.5×10 -6 / °C.

[0046] The room temperature strength of the alumina joints connected by glass-ceramics prepared in this example reaches 280 MPa, which is 30% higher than that of common glass joints.

Embodiment 3

[0048] This embodiment differs from Embodiment 1 in that:

[0049] In the method for connecting alumina ceramics with the glass-ceramic solder of this embodiment, the welding treatment system of step (3) in the brazing furnace is as follows: heating from room temperature to 350° C. at a rate of 10° C. / min, keeping the temperature for 60 minutes, and then heating for 5° C. Continue to heat to 1200°C at a rate of ℃ / min, and after holding for 40 minutes, cool to 860°C at a rate of 20°C / min, and hold for 1 hour.

[0050] The room temperature strength of the alumina joints connected by glass-ceramics prepared in this example reaches 274 MPa, which is 27.5% higher than that of ordinary glass joints.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com