Liquid medium conveying device

A technology for transmission devices and liquid media, which is applied in liquid distribution, transportation or transfer devices, distribution devices, transportation and packaging, etc. It can solve the problems that the flow rate and flow rate of liquid media are not easy to be controlled, and the transmission efficiency is low, so as to achieve good control, Avoid variations in delivery speed, pressure and flow stabilization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the technical solutions and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below.

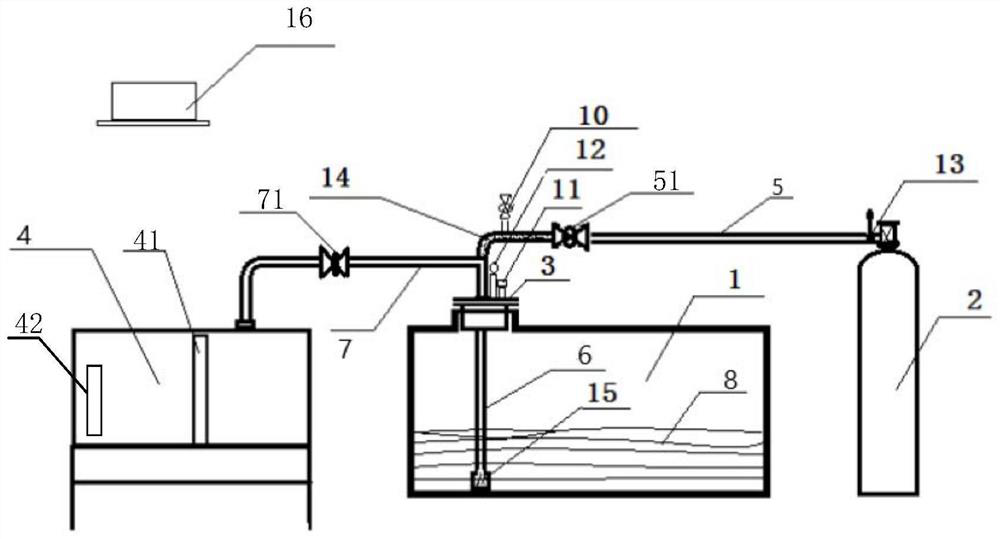

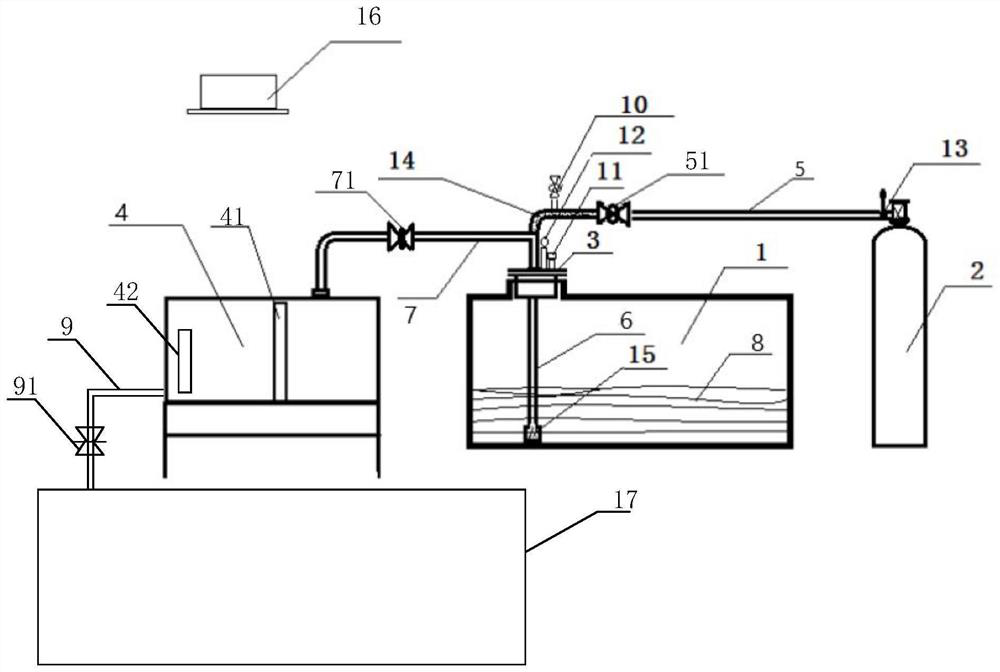

[0052] figure 1 It is a schematic structural diagram of a liquid medium transmission device provided according to an embodiment of the present disclosure. see figure 1, the transmission device includes: a first container 1, a second container 4, a controller 16, a liquid level gauge 41, a viscometer 42, a sealing assembly 3, a first delivery pipe 5, a first control valve 51, a second delivery pipe 6. The second control valve 71, the third delivery pipe 7 and the air supply unit 2;

[0053] The sealing assembly 3 is arranged at the container mouth of the first container 1, and is used for sealing the first container 1;

[0054] One end of the first delivery pipe 5 communicates with the first container 1 through the sealing assembly 3; the other end of the first delivery pipe 5 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com