Damper live-line disassembly and assembly robot based on unmanned aerial vehicle auxiliary on-line

A technology of robots and unmanned aerial vehicles, applied in the direction of manipulators, hoisting devices, lifting devices, etc., can solve problems such as mechanical fatigue, loss, displacement, narrow working space, and low power failure tolerance, so as to reduce weight and ensure safety Good performance and maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

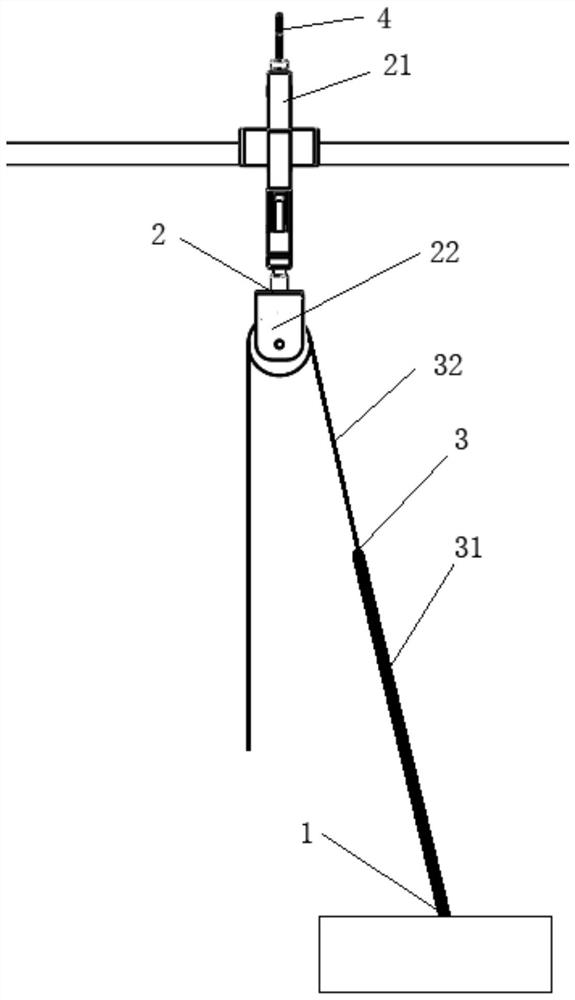

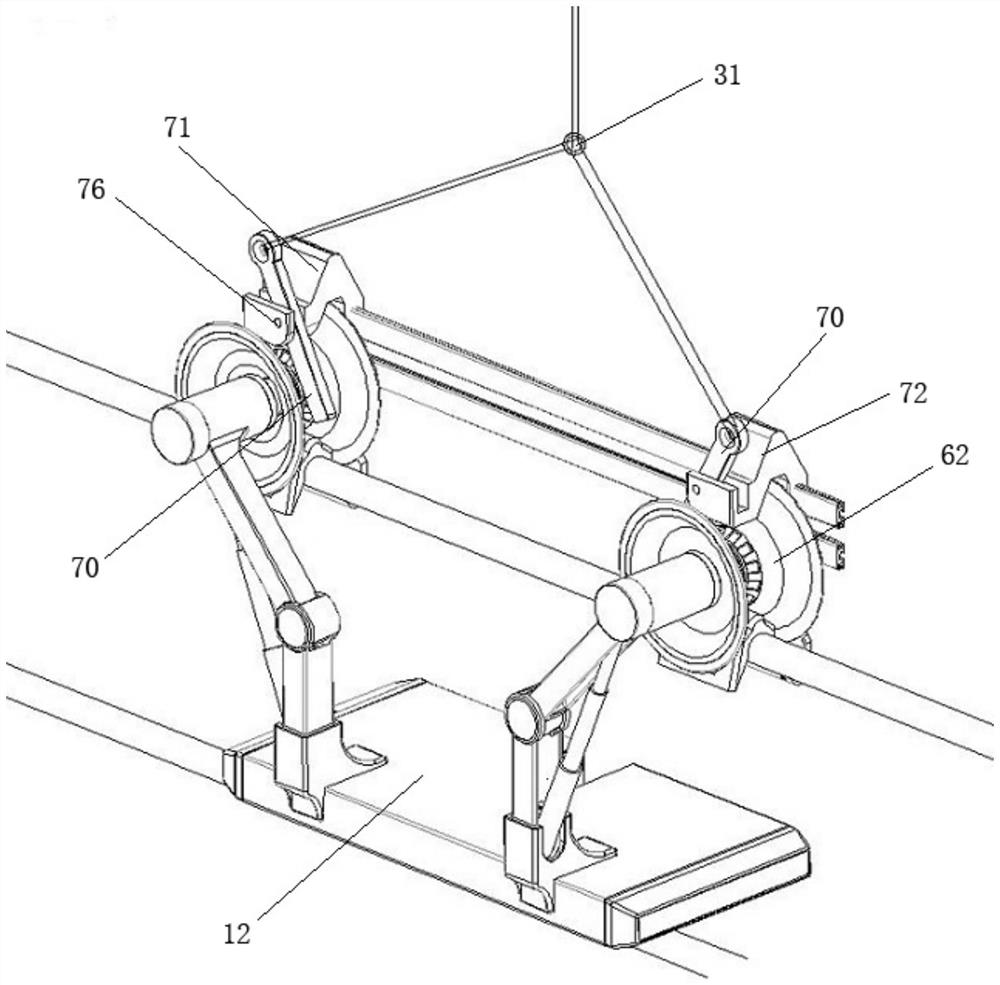

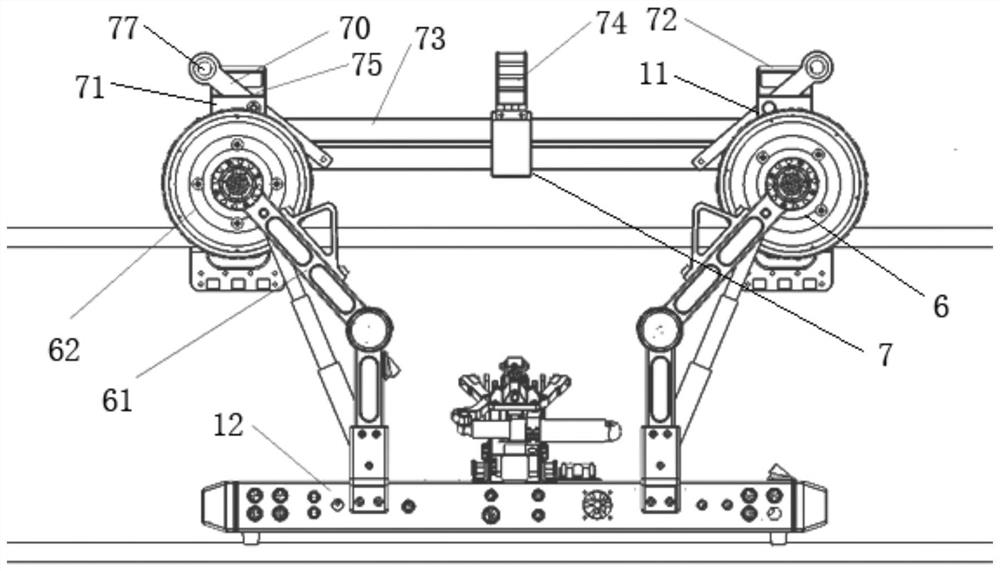

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a kind of anti-vibration hammer live disassembly robot based on UAV-assisted on-line, including robot main body 1, traction rope 3 and hoisting pulley block 2 suspended on the wire, the hoisting pulley block 2 is provided with UAV The connected connecting mechanism 4, and the dead bolt 5 that is rotatably connected to the hoisting pulley block 2, the first torsion spring 50 is arranged on the described dead bolt 5, and the described connecting mechanism 4 is linked with the dead bolt 5. When the connecting mechanism 4 and When the UAV is connected, the dead bolt 5 is accommodated on the hoisting pulley block 2 under the pulling force of the connecting mechanism. When the connecting mechanism 4 is separated from the UAV, the dead bolt 5 resets under the action of the first torsion spring 50, and the The lifting pulley block 2 is locked on the wire, and the traction rope 3 includes a lifting sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com