Coarse krypton and xenon purification device

A krypton-xenon and mounting rack technology is applied in the field of crude krypton-xenon purification devices, which can solve the problems of hidden safety hazards, difficult equipment entry and installation, large space occupation, etc., to ensure coverage, convenient location movement, and practicality sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

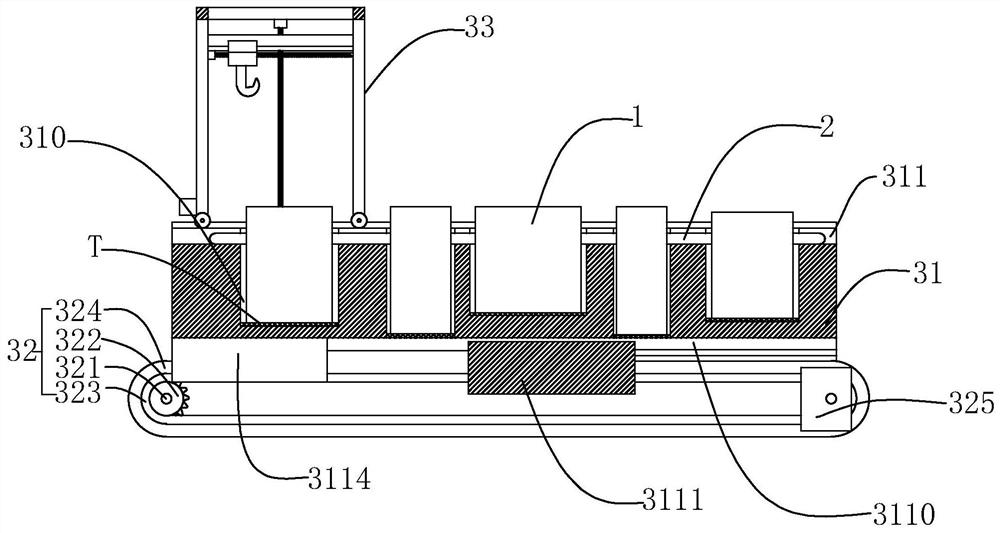

[0034] The invention discloses a crude krypton-xenon purification device, which includes a krypton-xenon purification device 1 and a connecting pipeline 2 connected to the krypton-xenon purification device 1. In the specific embodiment 1 of the present invention, the krypton-xenon purification device 1 is installed with Mounting frame 3, described mounting frame 3 comprises mounting platform 31, is located at the bottom of mounting platform 31 and is used for moving mechanism 32 of mounting frame 3 moving on the ground and is located on mounting platform 31 and is used for lifting krypton-xenon purification equipment 1 The lifting mechanism 33, the installation platform 31 is provided with a plurality of installation grooves 310 for krypton-xenon purification equipment 1 to be embedded, the installation platform 31 is provided with a guide groove 311 communicating with the installation grooves 310, and the connecting pipe The road 2 is installed in the guide groove 311 .

[00...

Embodiment 2

[0037] In Embodiment 2 of the present invention, the moving mechanism 32 includes two driving rollers 321 arranged parallel to the bottom of the installation platform 31, a sprocket 322 arranged at the end of each rotating roller 321, and respectively The transmission chain 323 disposed on the two sprockets 322 on the same side of the rotating roller 321 , the transmission cover belt 324 sleeved on the transmission chain 323 , and the first synchronous motor 325 disposed on the two transmission rollers 321 .

[0038] By adopting the above technical solution, the first synchronous motor is turned on, the output end of the first synchronous motor drives the transmission roller to rotate, the sprocket on the transmission roller rotates synchronously, and then drives the transmission chain to rotate around the sprocket, and is sleeved on the transmission The transmission covering belt on the chain rotates synchronously with the transmission chain, and then the driving covering belt...

Embodiment 3

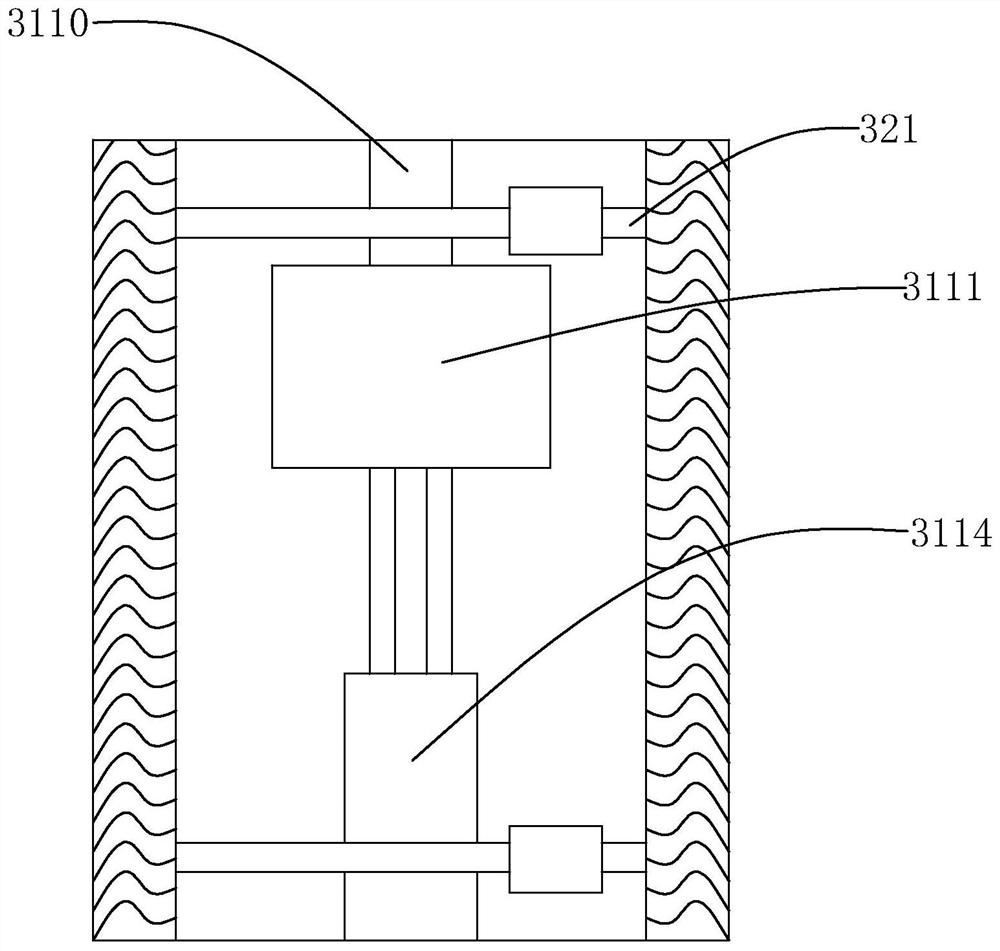

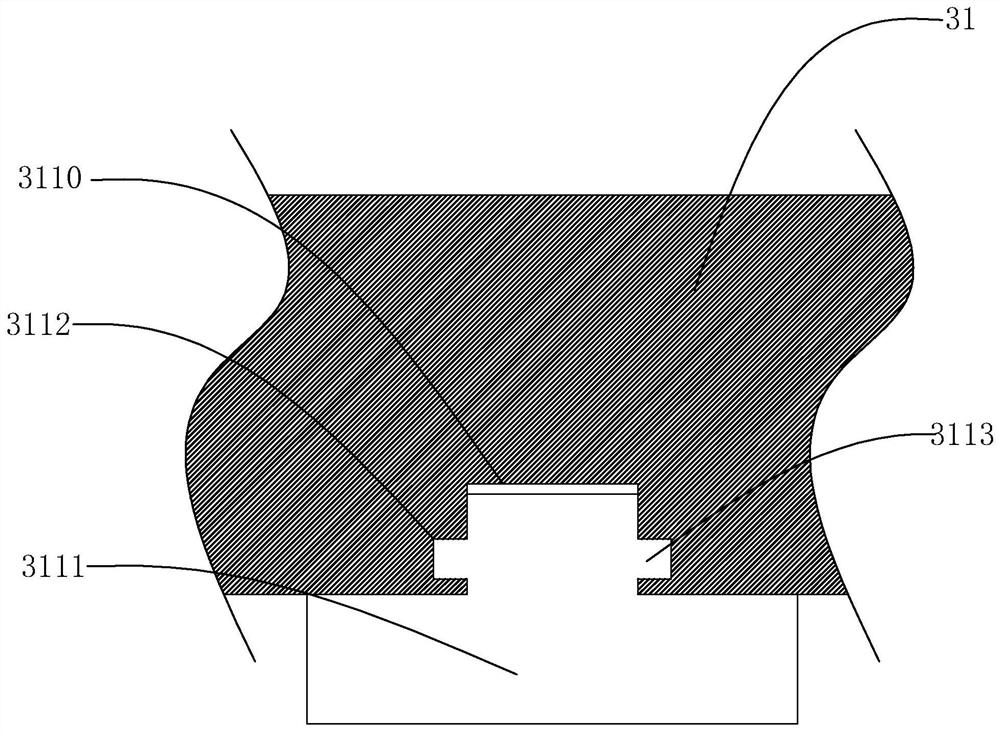

[0040] In the specific embodiment 3 of the present invention, the bottom of the installation platform 31 is provided with a slot 3110 along the length direction of the installation platform 31, and a gravity block 3111 is embedded in the slot 3110, and the gravity block 3111 is in the groove. 3110 can reciprocate along the length direction of the slot 3110, the slot wall of the slot 3110 is provided with a limit slot 3112 consistent with the length direction of the slot 3110, the side wall of the gravity block 3111 is provided with a The limit block 3113 adapted to the limit slot 3112 is fixedly provided with a first hydraulic cylinder 3114 at the end of the slot 3110 in the length direction, and the output direction of the first hydraulic cylinder 3114 is in line with the slot 3110 The length direction of the first hydraulic cylinder 3114 is fixedly connected with the gravity block 3111.

[0041] By adopting the above technical solution, the first hydraulic cylinder is opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com