Leveling equipment for train parts

A component and leveling technology, which is applied in the field of leveling equipment for train components, can solve problems such as threats to human health, inconvenient operation, and high cost, and achieve good correction effects, safe heating methods, and good stress effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

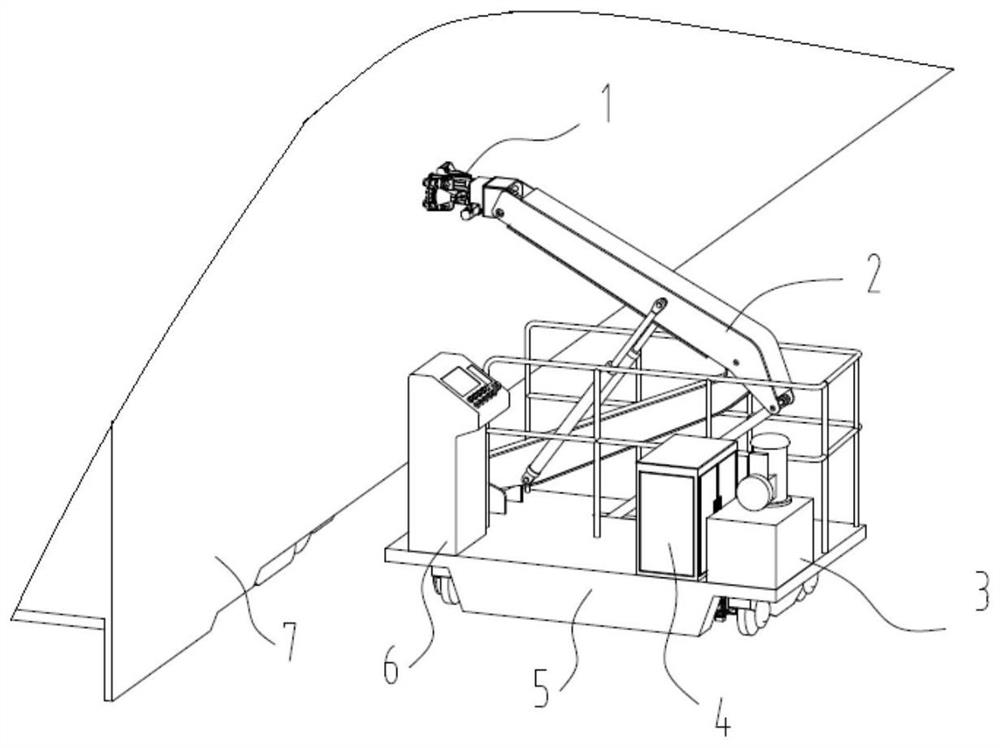

[0031] see figure 1 , a leveling equipment used for train parts, including a mobile car body 5, a lifting device arranged on the mobile car body 5, a leveling head arranged on the lifting device, a hydraulic station 3, a cooling The water tank 4 is connected to the operating table 6, the hydraulic station 3 is connected to the lifting device, and the cooling water tank 4 is connected to the induction heating tool 101 arranged on the leveling head;

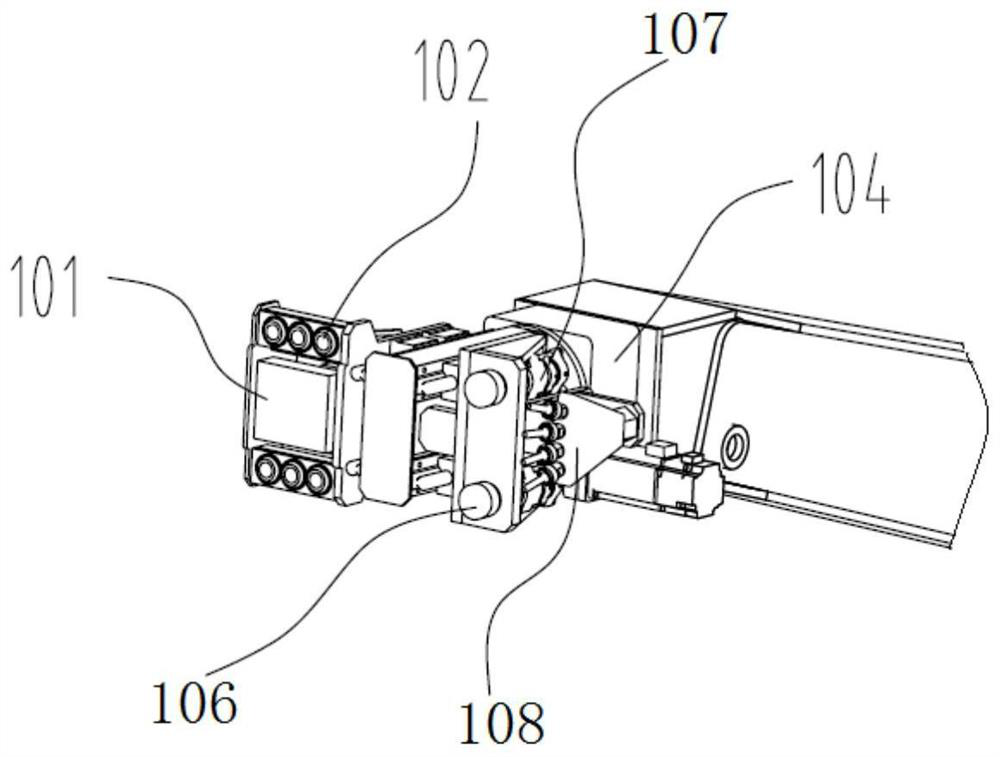

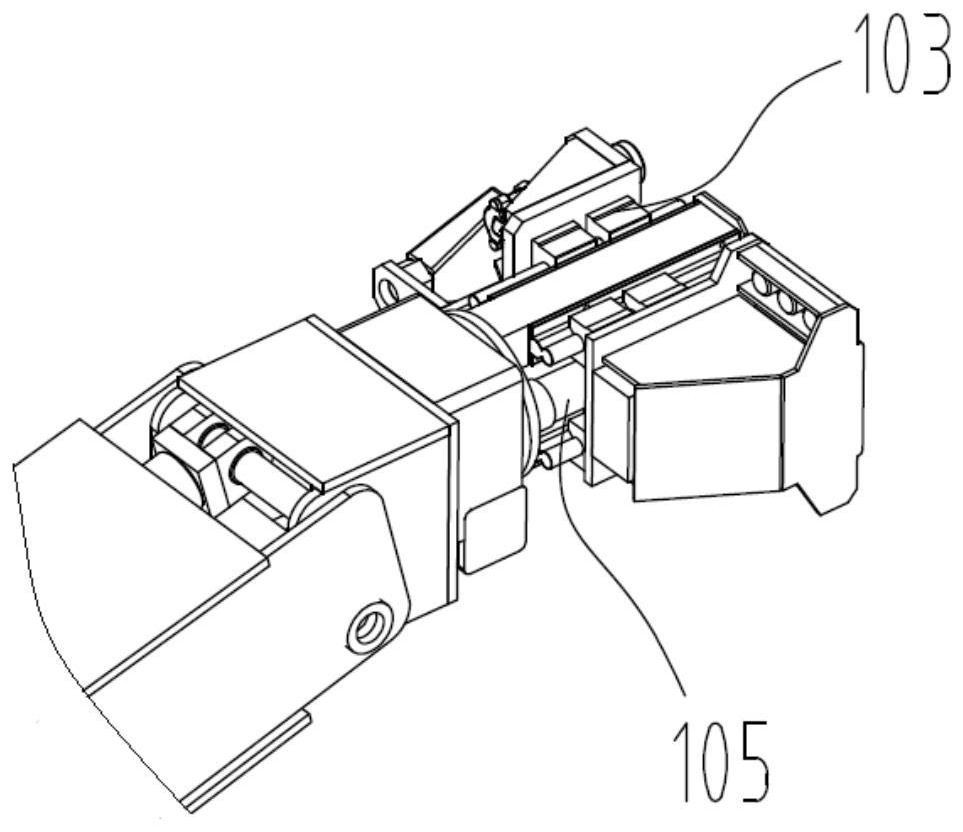

[0032] The leveling head includes an induction heating tool 101, a hammering tool 107 and a water spray assembly, and the leveling head is connected with the rotating mechanism 104 provided on the lifting device.

[0033] The leveling head can move approximately vertically along the height direction of the train car body 7 with the lifting arm, and can move linearly along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com