Rotary ultrasonic grinding machine tool and application

A rotary ultrasonic and grinding technology, which is applied to the parts of grinding machine tools, grinding workpiece supports, grinding drive devices, etc. The problem of long route and other problems can reduce grinding burns, improve processing quality and reduce grinding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further illustrate the technical solution of the present invention, the present invention will be further described below through examples.

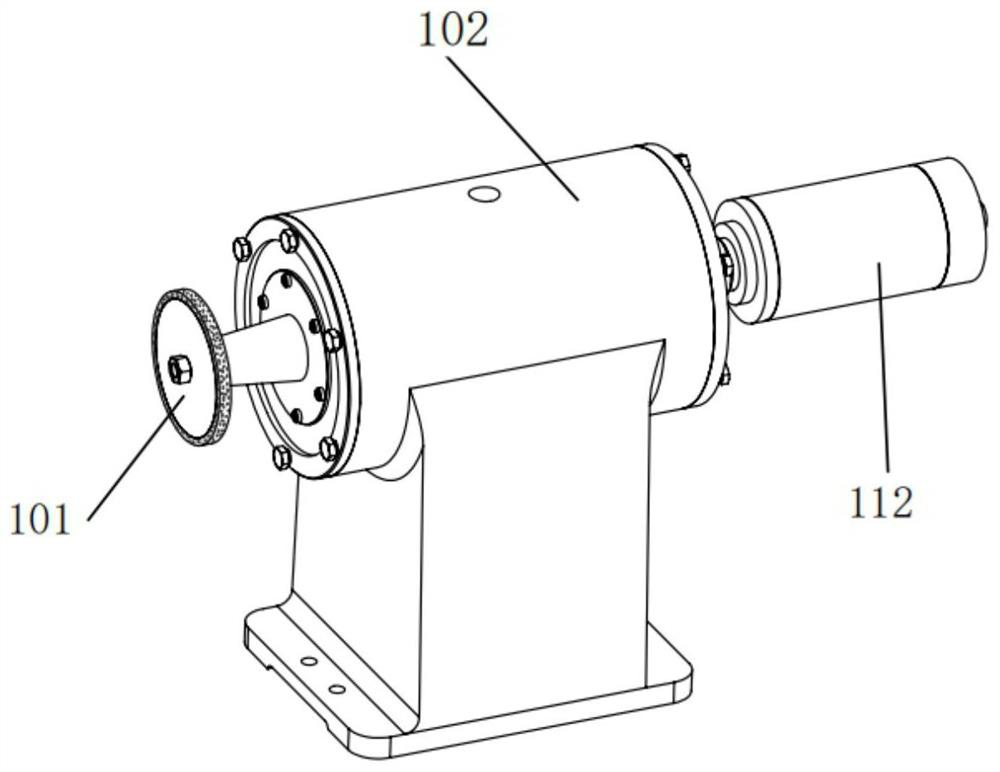

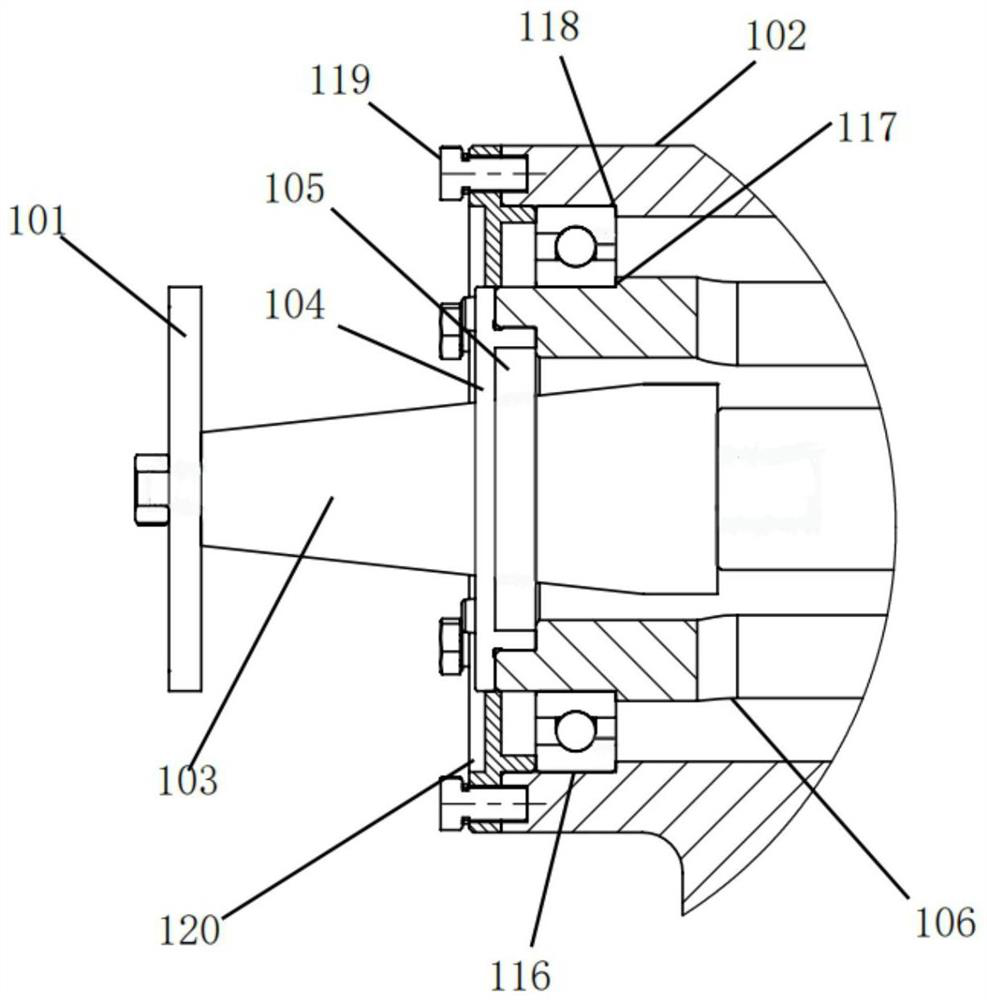

[0043] Such as Figure 1 to Figure 10 As shown, a rotating ultrasonic grinding spindle includes a grinding wheel 101, the grinding wheel 101 is installed at the output end of the horn 103, and a horn flange 104 is arranged in the middle of the horn 103, and the horn flange 104 is arranged in the middle of the horn 103. The horn flange 104 is connected with the end surface of the hollow sleeve 106 through a screw fixing assembly, and a fitting ring 105 is arranged on the right side of the horn flange 104, and the outer peripheral surface of the fitting ring 105 is connected with the hollow sleeve. The inner surface of the sleeve 106 is in contact, and the large-end mandrel of the horn 103 extends into the hollow sleeve 106 to connect with the output end surface of the transducer 107, and a copper sheet 108 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com