Microbial remediation method for heavy metal contaminated soil in retired slag yard of smelting plant

A technology for microbial remediation and contaminated soil, which is applied in the field of microbial remediation of heavy metal contaminated soil in decommissioned slag fields of smelters, and can solve the problems of secondary pollution, high operating costs, and easy redissolving of heavy metal sludge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

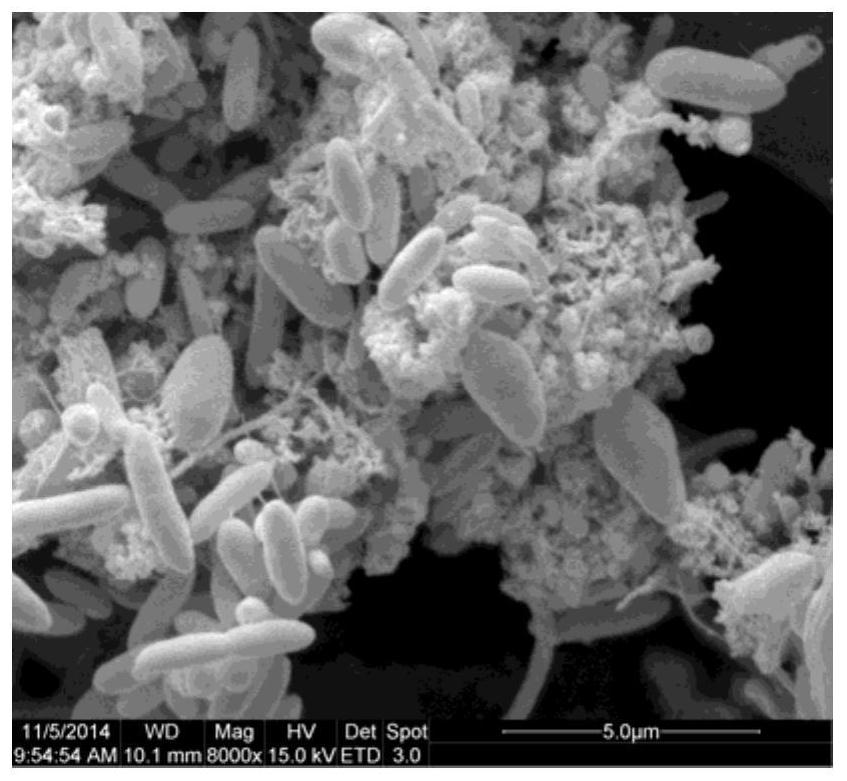

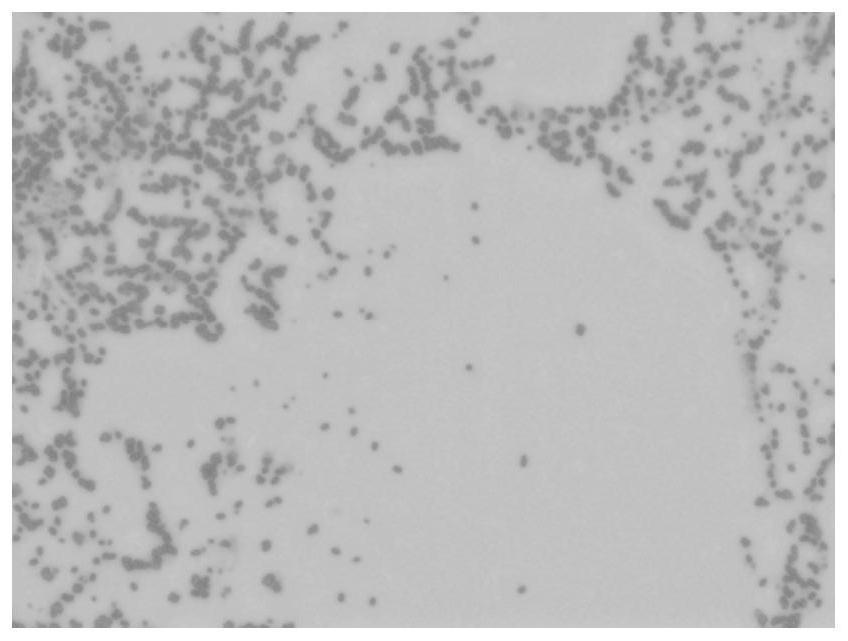

Image

Examples

Embodiment 1

[0039] Example 1: Microbial in-situ mineralization repair method for lead-zinc tailings reservoir

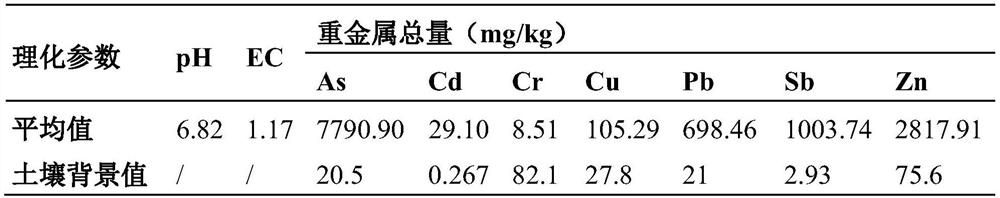

[0040] Using the above-mentioned microbial remediation technology, a lead-zinc tailings pond was used as the main demonstration area for microbial in-situ mineralization remediation. The physical and chemical properties of the tailings samples are shown in Table 1.

[0041] Table 1 Physical and chemical parameters of tailings samples

[0042]

[0043] Before the restoration of the tailings pond, it was close to desertification, and the water and soil loss was serious. After 2 months of in-situ remediation with microorganisms, the solidification of free heavy metals in the tailings, the tailings reservoir area has become biologically friendly, and a large number of bryophytes and a small amount of herbaceous plants have begun to grow. In about 6 months, the use of microbial in-situ restoration technology has been completely greened. Drilling rigs were used to drill groundwa...

Embodiment 2

[0044] Example 2 Wet detoxification chromium slag stockyard contaminated soil microbial remediation method

[0045] Take 150g of each uniformly mixed sample into a bottle, add 100mL of water, culture medium, and mixed bacteria solution, and let it stand in an incubator at room temperature for 3-4 days to determine the effect of microbial restoration.

[0046] 1) pH and Eh changes before and after restoration

[0047] The Eh of the repair group of the three samples added with the mixed bacteria solution dropped from the initial 260-300mV to -400mV--260mV, and the decrease was obvious, and the Eh of the blank control group tended to be stable (250mV-310mV); the pH of the repair group added with the mixed bacteria solution Stable at 7.5-8.5, the stable form of chromium in this pH and Eh range is Cr(OH) 3 .

[0048] 2) Microbial restoration effect

[0049] Compared with the data of the blank control group added with water and culture medium, the chromium repair effect of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com