Equipment for optocoupler packaging structure and packaging method

A packaging structure, optocoupler technology, applied in the coupling of optical waveguides, optics, light guides, etc., can solve the problem of reducing the speed of production and the number of unqualified optocoupler products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

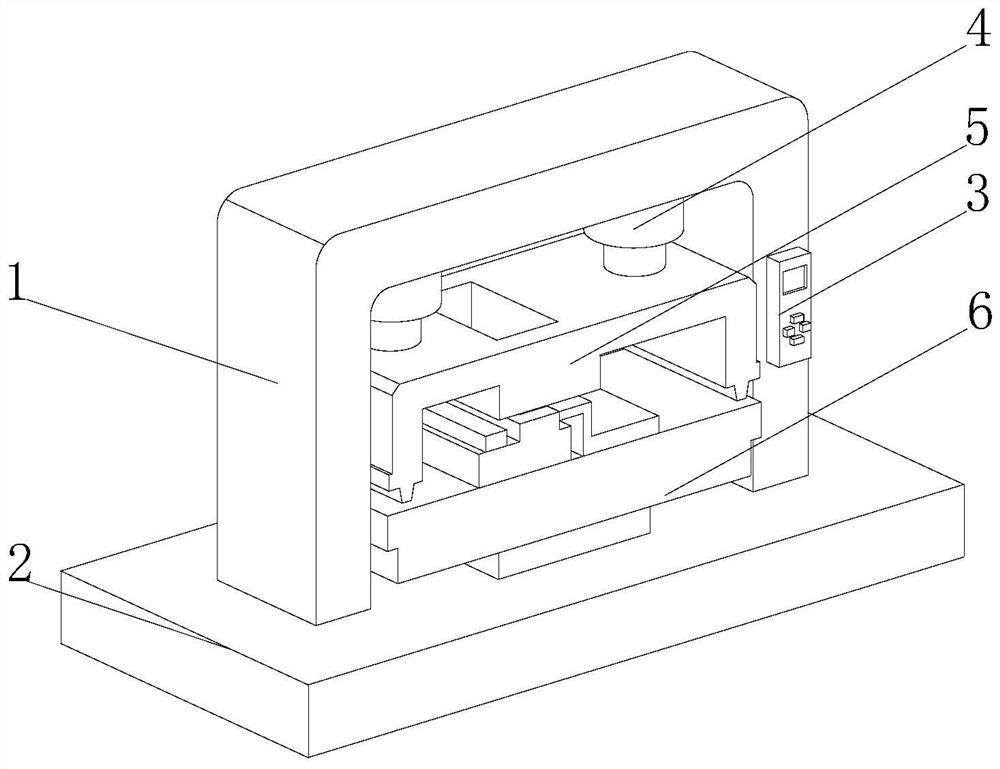

[0037] Such as Figure 2 to Figure 3 As shown, the present invention provides a technical solution: a device for optocoupler packaging structure, including a fixed shell 1 and a base 2, one end of the fixed shell 1 is fixedly connected to the top of the base 2, and the fixed shell 1 One side of the fixed shell 1 is provided with a controller 3, and one side of the fixed shell 1 is fixedly connected with a lifting device 4, and the end of the lifting device 4 away from the fixed shell 1 is fixedly connected with a moving fixture 5, and the top of the base 2 is connected to the moving fixture. The corresponding position of the fixture 5 is fixedly connected with a fixed fixture 6, and one end of the moving fixture 5 close to the fixed fixture 6 is fixedly connected with a positioning projection 7, and the two sides of the fixed fixture 6 are fixedly connected with a positioning projection at a position corresponding to the positioning projection 7. Groove 8, glass windows are pr...

Embodiment 2

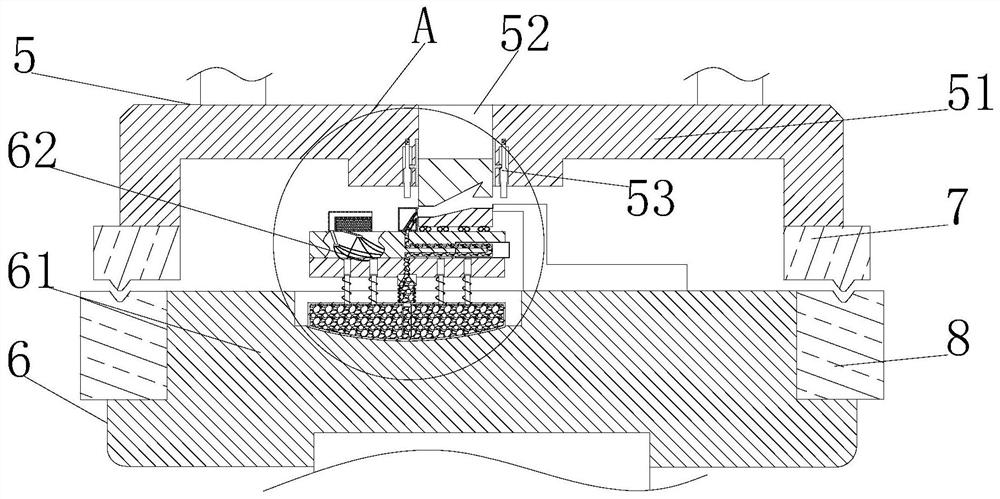

[0040] Such as Figure 3 to Figure 9 As shown, the present invention provides a technical solution on the basis of Embodiment 1: a device for an optocoupler packaging structure, the positioning adhesive mechanism 62 includes an adhesive shell 621, and the adhesive shell The top of the body 621 is fixedly connected with an air purification mechanism 622, and the middle part of the viscose shell 621 close to the air purification mechanism 622 is connected with a glue injection mechanism 623, and the air purification mechanism 622 and the glue injection mechanism 623 are far away from the glue One end of the glue shell 621 is fixedly connected with a fixed plate 624 through it, and the top of the fixed plate 624 is fixedly connected with a mounting plate 625. The plate 625 is fixedly connected, and the side of the mounting plate 625 close to the air purification mechanism 622 is fixedly connected with a glue injector 626, and the glue injector 626 communicates with the glue injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com