Tunnel construction method for breaking rocks by using high-pressure water

A technology of tunnel construction and high-pressure water, which is applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of waste of resources, abnormal damage of metal tools, and decreased efficiency of rock breaking, so as to save tool costs and solve abnormal damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

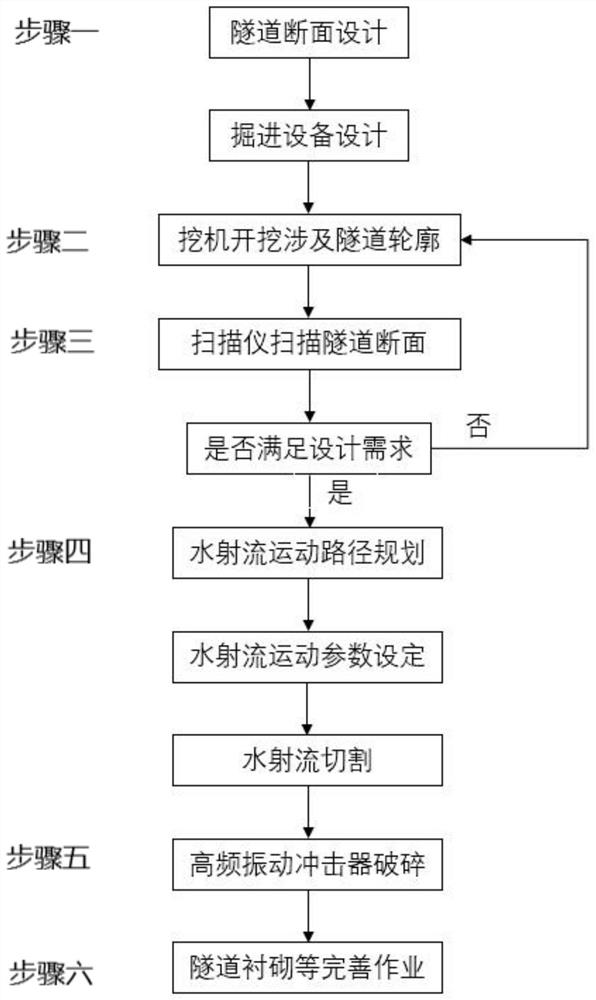

[0020] Such as figure 1 As shown, the embodiment of the present invention provides a tunnel construction method utilizing high pressure water to break rock, comprising the following steps:

[0021] Step 1. Design the section of the tunnel, and plan the trajectory of the fluidic component and the location of the vibration impactor according to the section shape of the tunnel;

[0022] Step 2, excavating the contour of the actual tunnel according to the section shape of the tunnel;

[0023] Step 3: Scan the cross-sectional shape of the actual tunnel, and compare and trim it with the cross-sectional shape of the tunnel;

[0024] Step 4: Form a water-cutting groove of a set shape on the face of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com