Inner-cooling drill bit applied to machining of through hole including step countersink

A step countersunk and drill bit technology, which is applied in metal processing equipment, drilling/drilling equipment, drill repairing, etc., can solve the problems of decreased overall tool life, reduced coolant flow, and unfavorable cooling of the main cutting edge, etc., to achieve reduction The Effect of Tool Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

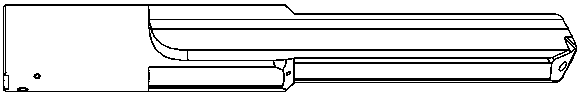

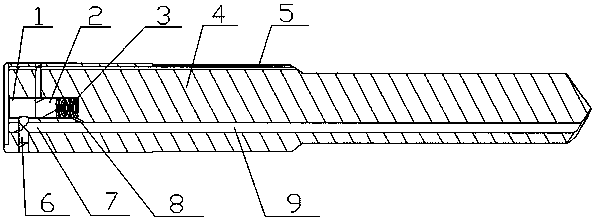

[0017] A drill bit with cooling holes for through hole processing including stepped counterbore, its overall structure is as follows figure 1 As shown, this case cites the use of carbide straight groove drill bits to process gray cast iron. Internal structure such as figure 2 As shown, its diameter is D1=14.5mm (main cutting edge part), D2=18mm (counterbore secondary cutting edge part), and its length is L1=150mm. Four cooling channels 5 and 9 are pre-cast inside (D1 / D2 each two bar), arranged according to an angle of 60 degrees, and the subsection leads to the flank of the cutting edge; the prefabricated channel of the drill bit needs to be connected with the main channel for liquid supply, and secondary processing is required. The diameter of the main channel is D5=4mm, and the depth is L2 =20mm, the diameters of the reworked Unicom holes are D3 and D4, and the main liquid supply channel is also drilled with a pressure relief hole 6 of D6=0.5mm to prevent the accumulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com