High-strength seamless line pipe and manufacturing method thereof

A seamless line pipe and high-strength technology is applied in the field of high-strength seamless line pipe and its preparation. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

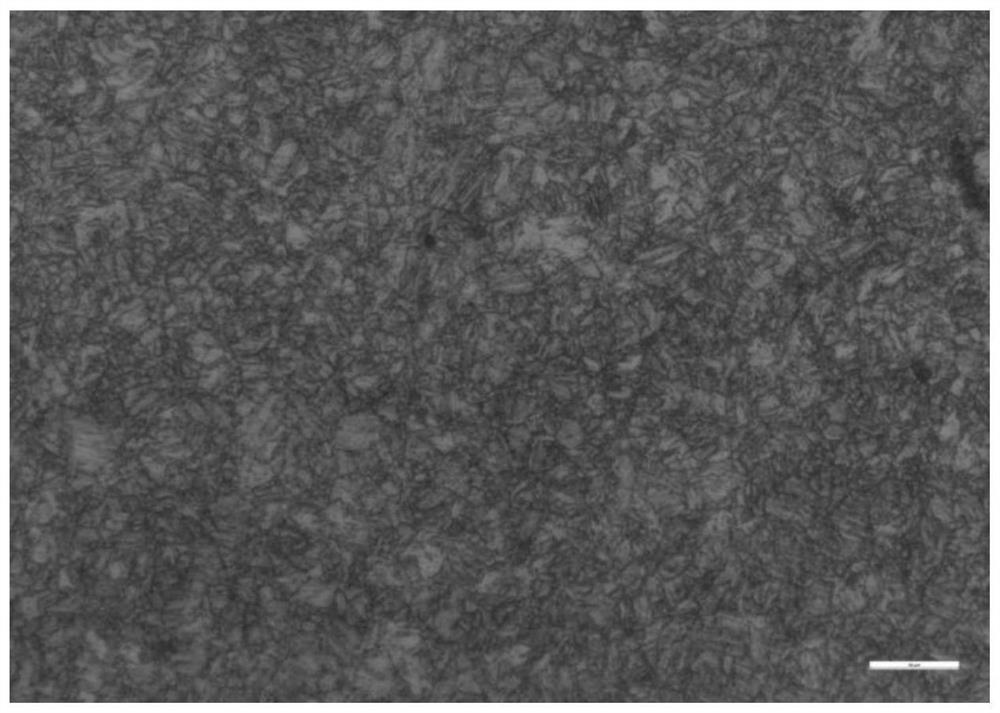

Image

Examples

Embodiment 1

[0028] The embodiment of the present invention provides a high-strength seamless line pipe, the chemical composition of which is:

[0029] C 0.06%, Si 0.35%, Mn 1.75%, Ti 0.03%, Mo 0.25%, Cr 0.48%, Mg0.001%, S 0.003%, P 0.008%, the rest is Fe and unavoidable impurities, CE Pcm 0.20%.

[0030] The preparation steps of the above-mentioned high-strength seamless line pipe are as follows:

[0031] Using scrap steel as raw material, through 80t electric arc furnace melting, ladle refining and continuous casting process, the continuous casting round billet with the same chemical composition as the above-mentioned high-strength seamless line pipe is produced; the continuous casting round billet is made by heating and perforating in the ring furnace Capillary, the capillary is rolled by a five-stand PQF unit to obtain a waste pipe, and the waste pipe is removed by a three-stand pipe removal machine, micro-tensioned, and cooled by a step-by-step cooling bed to make an outer diameter ...

Embodiment 2

[0040] The embodiment of the present invention provides a high-strength seamless line pipe, the chemical composition of which is:

[0041] C 0.08%, Si 0.25%, Mn 1.55%, Ti 0.02%, Mo 0.15%, Cr 0.55%, Mg0.0012%, S 0.005%, P 0.009%, the rest is Fe and unavoidable impurities, CE Pcm 0.20%.

[0042] The preparation steps of the above-mentioned high-strength seamless line pipe are as follows:

[0043] Using scrap steel as raw material, through 80t electric arc furnace melting, ladle refining and continuous casting process, the continuous casting round billet with the same chemical composition as the above-mentioned high-strength seamless line pipe is produced; the continuous casting round billet is made by heating and perforating in the ring furnace Capillary, the capillary is rolled by a five-stand PQF unit to obtain a waste pipe, and the waste pipe is removed by a three-stand pipe removal machine, micro-tensioned, and cooled by a step-by-step cooling bed to make an outer diameter ...

Embodiment 3

[0052] The embodiment of the present invention provides a high-strength seamless line pipe, the chemical composition of which is:

[0053] C 0.09%, Si 0.30%, Mn 1.68%, Ti 0.01%, Mo 0.20%, Cr 0.35%, Mg0.002%, S 0.008%, P 0.007%, the rest is Fe and unavoidable impurities, CE Pcm 0.22%.

[0054] The preparation steps of the above-mentioned high-strength seamless line pipe are as follows:

[0055] Using scrap steel as raw material, through 80t electric arc furnace melting, ladle refining and continuous casting process, the continuous casting round billet with the same chemical composition as the above-mentioned high-strength seamless line pipe is produced; the continuous casting round billet is made by heating and perforating in the ring furnace Capillary, the capillary is rolled by a five-stand PQF unit to obtain a waste pipe, and the waste pipe is removed by a three-stand pipe removal machine, micro-tensioned, and cooled by a step-by-step cooling bed to make an outer diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com