A kind of high-strength toughness weldable corrosion-resistant and wear-resistant steel plate and its preparation method

A corrosion-resistant and wear-resistant technology with high strength and toughness, applied in the field of corrosion-resistant and wear-resistant steel plates, can solve the problems of poor welding performance, poor wear resistance, and insufficient toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

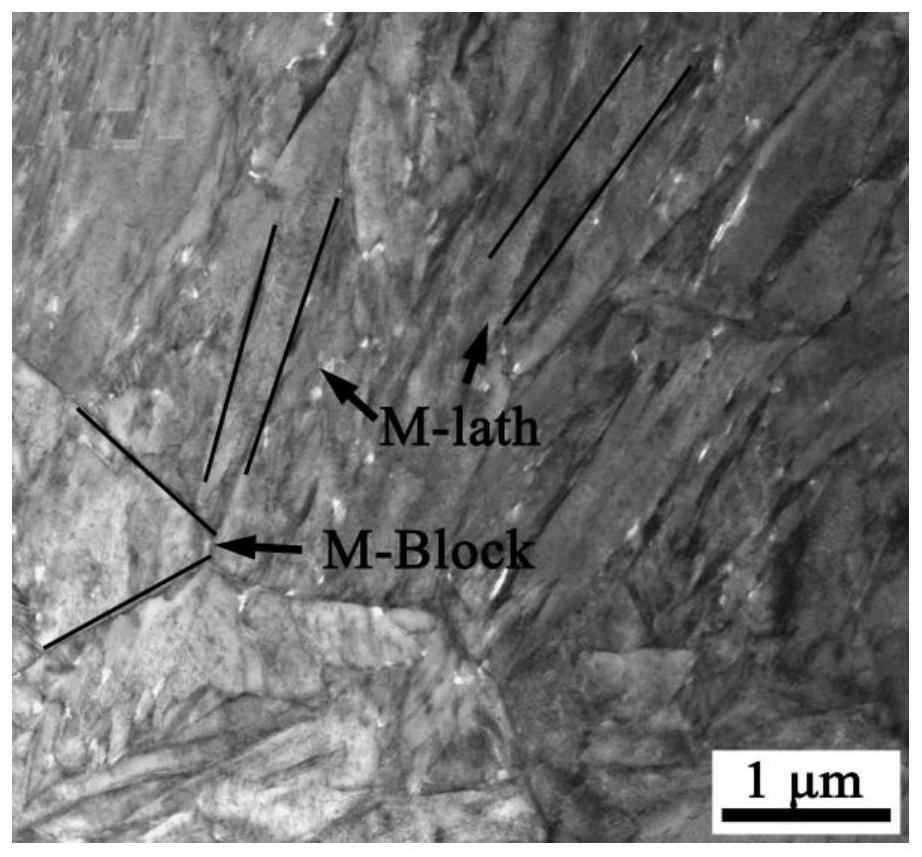

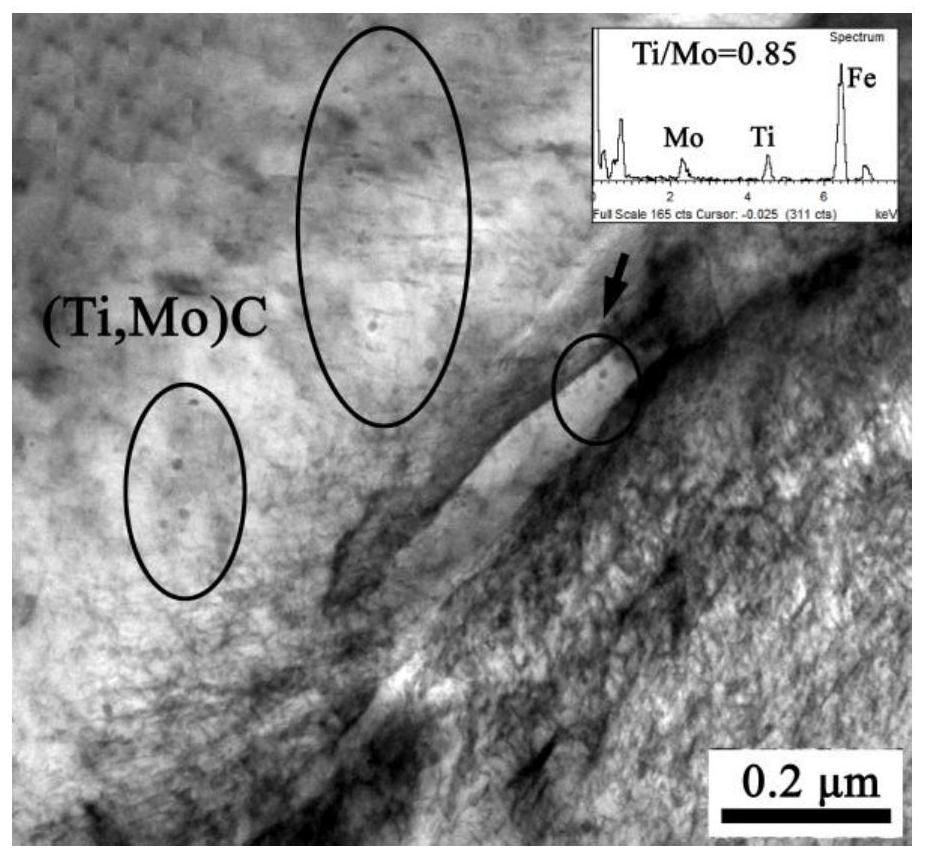

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, which is not intended to limit its protection scope.

[0047] A kind of high-strength toughness weldable corrosion-resistant and wear-resistant steel plate and its preparation method

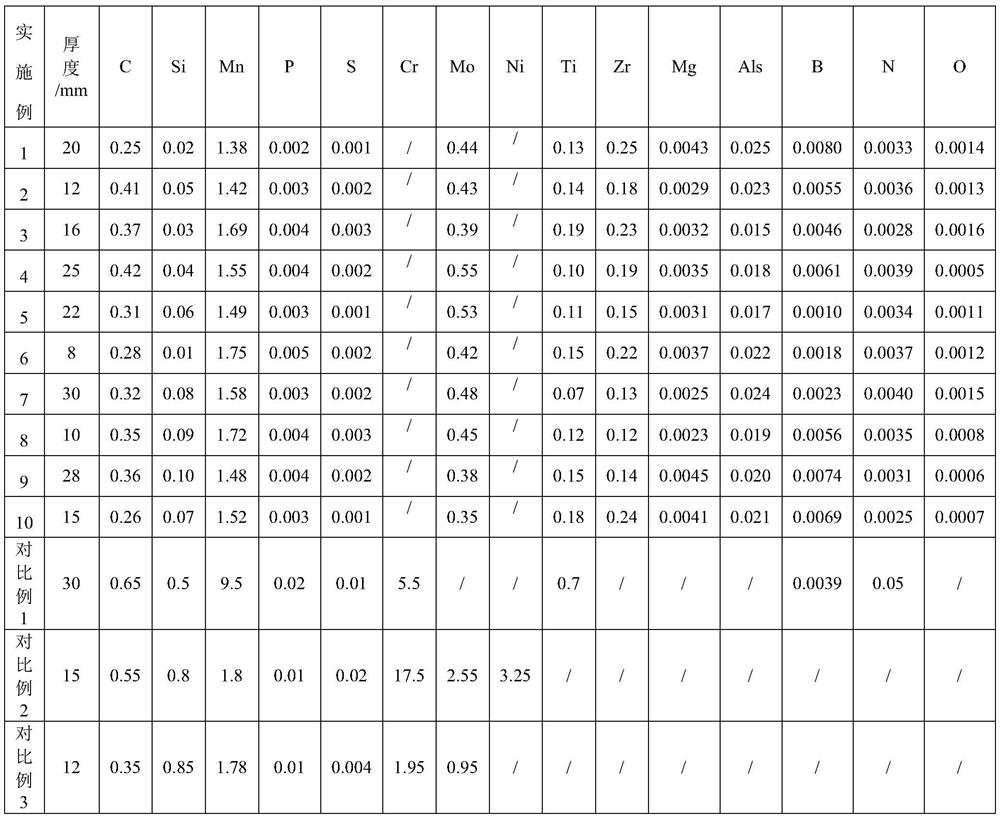

[0048] The components and contents of the high-strength toughness weldable corrosion-resistant and wear-resistant steel plate described in this specific embodiment are: C is 0.25-0.42wt%, Si is 0.01-0.10wt%, Mn is 1.35-1.75wt%, P≤0.005wt %, S≤0.002wt%, Mo is 0.35~-0.55wt%, Ti is 0.07~0.19wt%, Zr is 0.12~0.25wt%, Mg is 0.0023~0.0045wt%, Als is 0.015~0.025wt%, B 0.001-0.008wt%, N 0.0025-0.0040wt%, O 0.0005-0.0015wt%, and the rest are Fe and trace impurity elements.

[0049] Among the components and contents of the high-strength and toughness weldable corrosion-resistant and wear-resistant steel plate: Mo / Ti is 1.8-7.0, and Ti / Als is 3-13.

[0050] Preferably: the C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com