Polyacrylic acid-based self-healing elastic material as well as preparation method and application thereof

A technology of polyacrylic acid and elastic materials, which is applied in the field of self-healing elastic materials based on polyacrylic acid and its preparation, can solve the problems of elastomers being yellowish, and achieve the effect of simple preparation steps, low cost and good self-healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

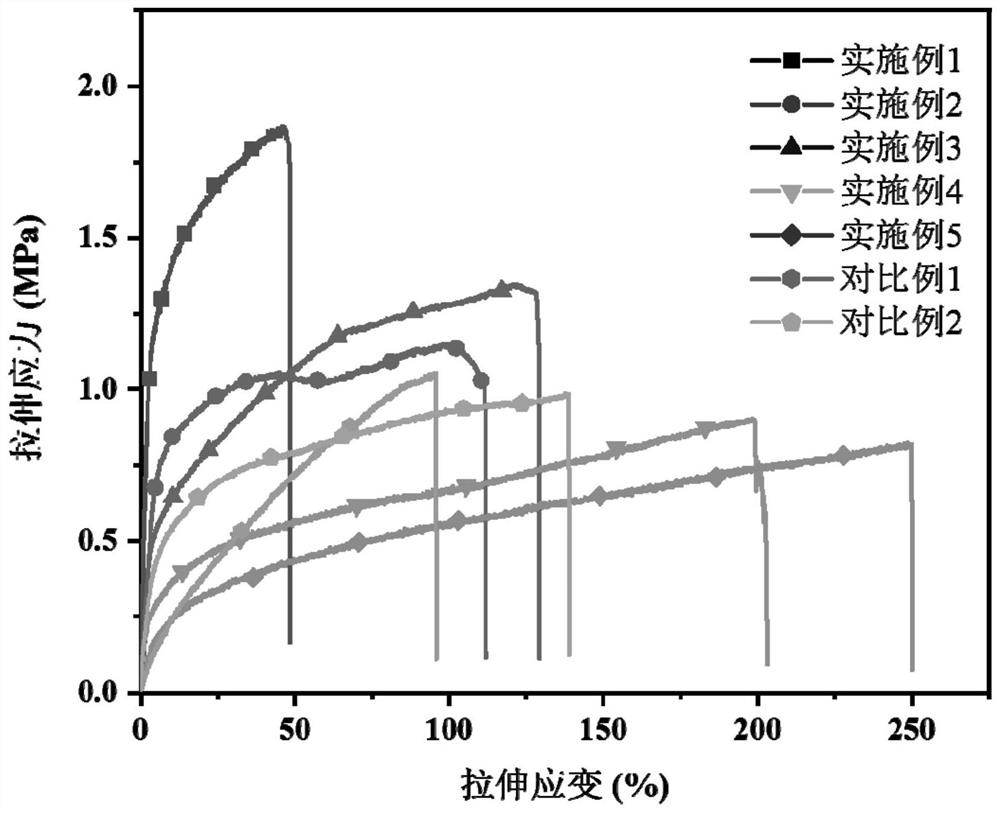

Embodiment 1

[0038] A kind of self-healing elastomer based on polyacrylic acid, its preparation method comprises the following steps:

[0039] 1) Add 4.8 g of polyacrylic acid with a weight average molecular weight of 3000 g / mol to 13 g of water and 8 g of ethanol solution, and magnetically stir at a speed of 300 r / min for 30 minutes to obtain a polyacrylic acid dispersion;

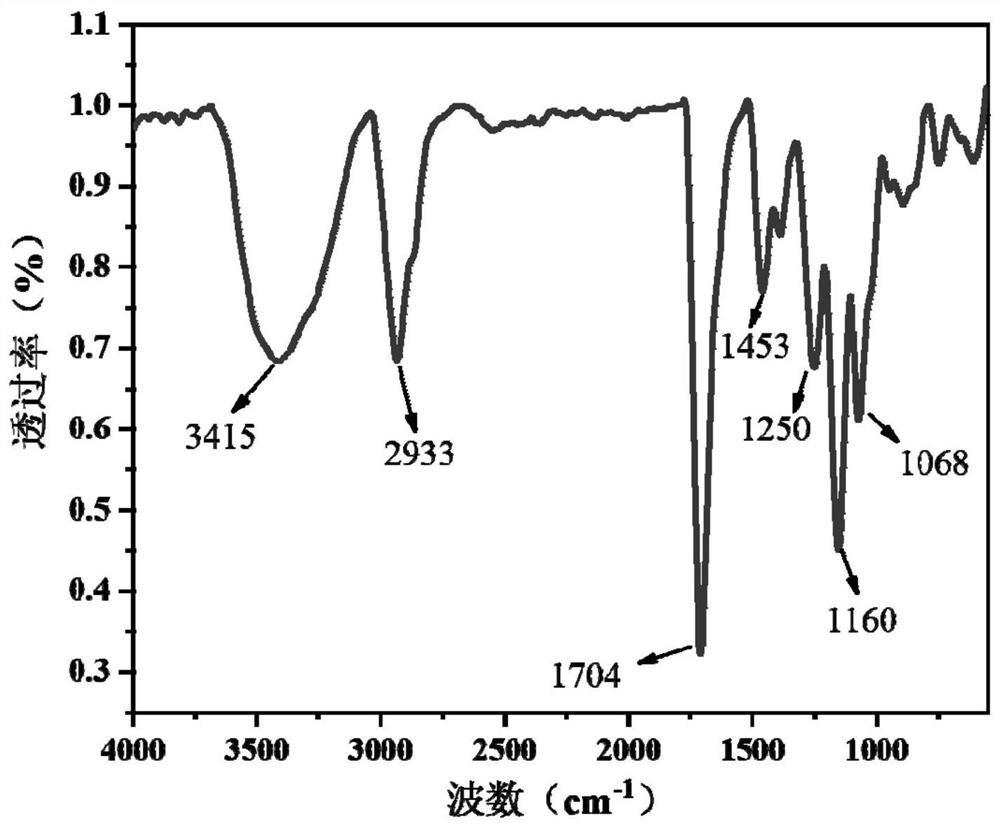

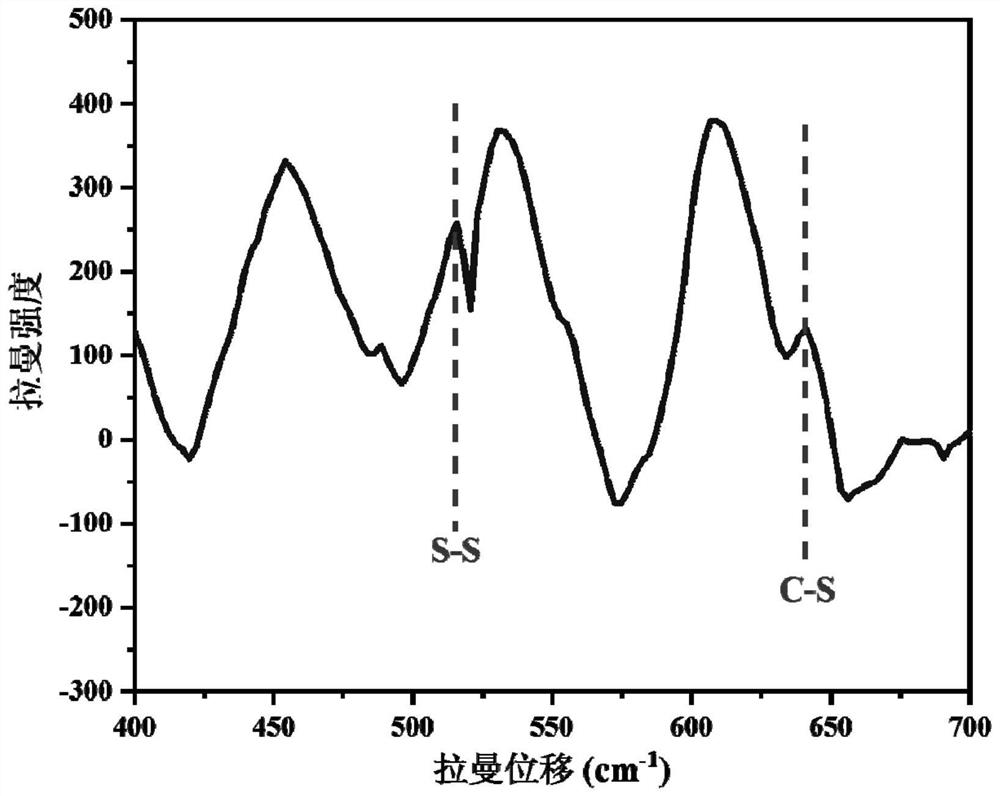

[0040] 2) 1.5g of hydroxyethyl acrylate, 3.5g of hydroxyethyl methacrylate, 1g of methacrylic acid, 0.2g of polyethylene glycol diacrylate with a number average molecular weight of 600g / mol, 0.01g of diallyl Add the 2-hydroxy-2-methylphenylpropane-1-one of base disulfide and 0.18g into the polyacrylic acid dispersion obtained in step 1), wrap the container with tinfoil to avoid light, and then 300r / min speed magnetic stirring for 60 minutes to obtain the precursor fluid;

[0041]3) Inject the precursor liquid obtained in step 2) into a polytetrafluoroethylene mold, irradiate with a UV lamp with a wavelength of 365nm...

Embodiment 2

[0043] A kind of self-healing elastomer based on polyacrylic acid, its preparation method comprises the following steps:

[0044] 1) Add 4.8 g of polyacrylic acid with a weight average molecular weight of 3000 g / mol to 13 g of water and 8 g of ethanol solution, and magnetically stir at a speed of 300 r / min for 30 minutes to obtain a polyacrylic acid dispersion;

[0045] 2) 2g of hydroxyethyl acrylate, 3g of hydroxyethyl methacrylate, 1g of methacrylic acid, 0.2g of polyethylene glycol diacrylate with a number average molecular weight of 600g / mol, 0.03g of diallyl diacrylate Add thioether and 0.18g of 2-hydroxyl-2-methylphenylpropane-1-one into the polyacrylic acid dispersion obtained in step 1), wrap the container with tin foil to avoid light, and then 300r / min Magnetic stirring at rotating speed for 60 minutes to obtain precursor fluid;

[0046] 3) Inject the precursor liquid obtained in step 2) into a polytetrafluoroethylene mold, irradiate with a UV lamp with a wavelength ...

Embodiment 3

[0048] A kind of self-healing elastomer based on polyacrylic acid, its preparation method comprises the following steps:

[0049] 1) Add 4.8 g of polyacrylic acid with a weight average molecular weight of 3000 g / mol to 13 g of water and 8 g of ethanol solution, and magnetically stir at a speed of 300 r / min for 30 minutes to obtain a polyacrylic acid dispersion;

[0050] 2) 2.5g of hydroxyethyl acrylate, 2.5g of hydroxyethyl methacrylate, 1g of methacrylic acid, 0.2g of polyethylene glycol diacrylate with a number average molecular weight of 600g / mol, 0.05g of diallyl Add the 2-hydroxy-2-methylphenylpropane-1-one of base disulfide and 0.18g into the polyacrylic acid dispersion obtained in step 1), wrap the container with tinfoil to avoid light, and then 300r / min speed magnetic stirring for 60 minutes to obtain the precursor fluid;

[0051] 3) Inject the precursor liquid obtained in step 2) into a polytetrafluoroethylene mold, irradiate with a UV lamp with a wavelength of 365n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com