Preparation method of electrochromic nickel oxide film

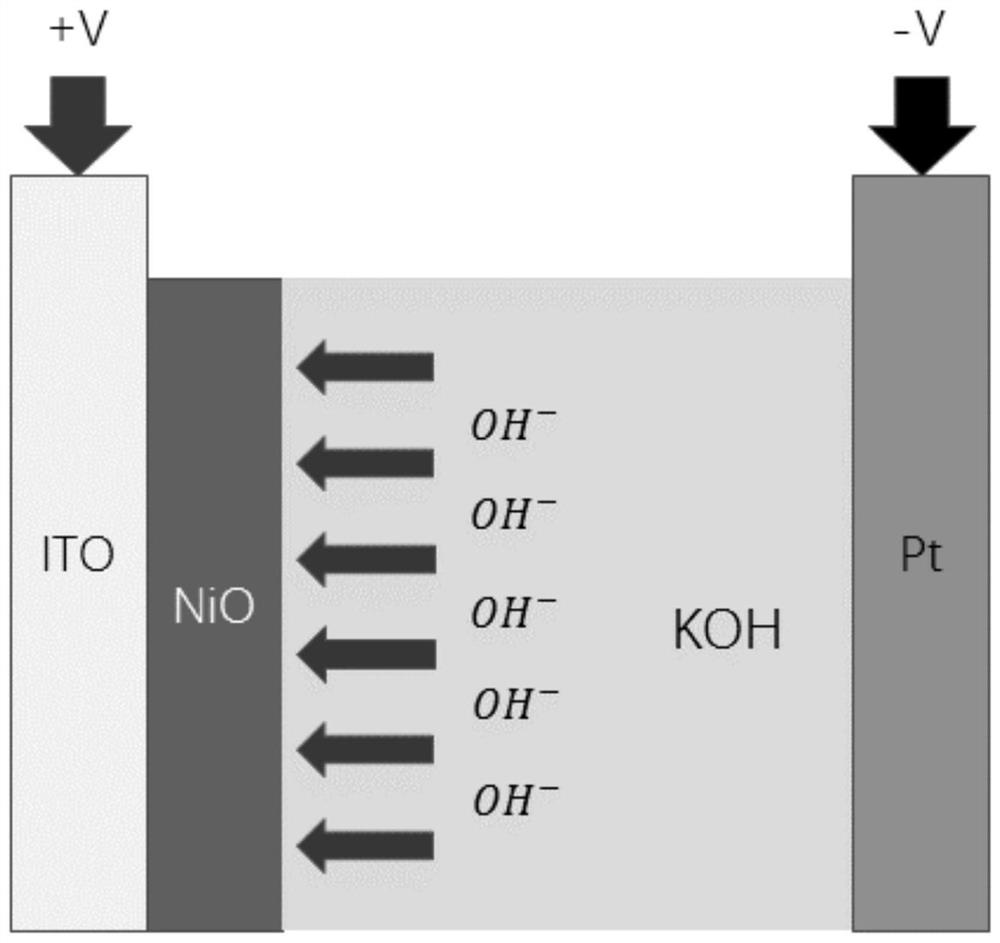

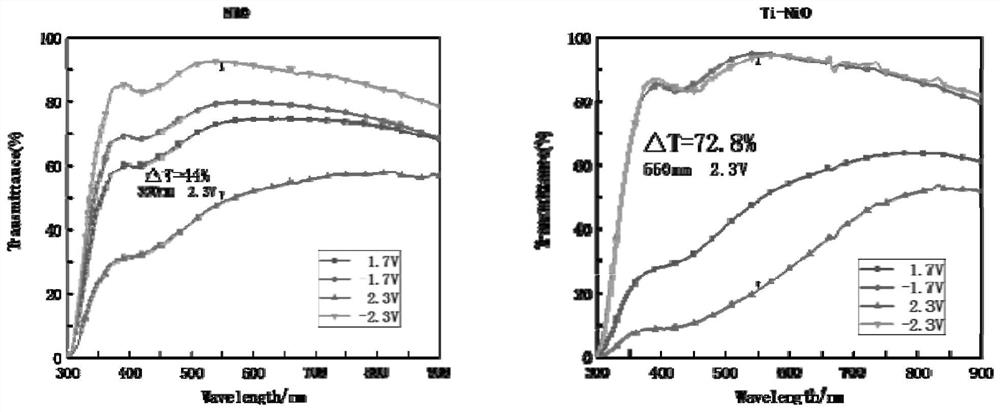

An electrochromic and nickel oxide technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of low optical modulation rate of nickel oxide film, cumbersome preparation process, complicated test method, etc., to reduce irreversible aggregation, wide application prospect, The effect of enhancing cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

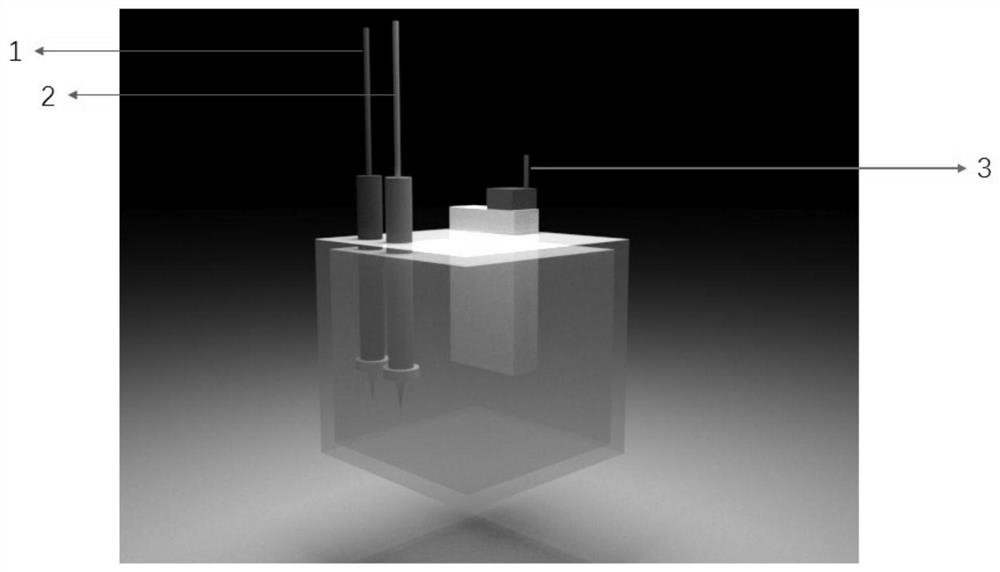

Image

Examples

Embodiment 1

[0040] This embodiment provides a method of preparing a electrochromic nickel oxide film comprising the steps of:

[0041] (1) 2.49 parts by weight of tetrahydrate acetate is added to 24.125 parts by weight of ethylene glycol methyl ether. After stirring, 0.85 parts by weight of titanate, stirred, stirred and uniform, and mixed solution, wherein nickel and titanium moisture The ratio is 4: 1, and the metal ion concentration is 0.5 mol / L.

[0042] (2) 0.632 parts by weight of monoethanolamine is added dropwise to the mixed solution obtained by adding step (1), stirring is uniform to clear the blue solution, and the molar ratio of monoethanolamine and metal ions is 1: 1;

[0043] (3) 0.1 parts by weight of the PVP powder is slowly added to the above-mentioned clear blue solution, and then stirred well, stirred in a 60 ° C water bath, resulting in a light green transparent sol;

[0044](4) The light-green transparent sol obtained by step (3) was allowed to stand for 24 h, and then ...

Embodiment 2

[0049] This embodiment provides a method of detecting a resistance to electrochromic nickel oxide film comprising the steps of:

[0050] (1) 2.074 parts by weight of tetrahydrate acetate is added to 24.125 parts by weight of ethylene glycol methyl ether. After stirring, 1.418 parts by weight of titanate tetrabutyl is added, and the mixed solution is obtained, where the mixed solution is mixed, wherein the molar of nickel and titanium. The ratio is 2: 1, the metal ion concentration is 0.5mol / L

[0051] (2) 0.632 parts by weight of monoethanolamine is added dropwise to the mixed solution obtained by adding step (1), stirring is uniform to clear the blue solution, and the molar ratio of monoethanolamine and metal ions is 1: 1;

[0052] (3) 0.1 parts by weight of the PVP powder is slowly added to the above-mentioned clear blue solution, and then stirred well, stirred in a 60 ° C water bath, resulting in a light green transparent sol;

[0053] (4) The light-green transparent sol obta...

Embodiment 3

[0058] This embodiment provides a method of detecting a resistance to electrochromic nickel oxide film comprising the steps of:

[0059] (1) 2.765 parts by weight of tetrahydrate nickel is added to 24.125 parts by weight of ethylene glycol methyl ether. After stirring, 0.473 parts by weight of titanate tetrabutyl is added, and the mixed solution is obtained, where the mixed solution is mixed, wherein nickel and titanium moisture The ratio is 8: 1, and the metal ion concentration is 0.5mol / L;

[0060] (2) 0.632 parts by weight of monoethanolamine is added dropwise to the mixed solution obtained by adding step (1), stirring is uniform to clear the blue solution, and the molar ratio of monoethanolamine and metal ions is 1: 1;

[0061] (3) 0.1 parts by weight of the PVP powder is slowly added to the above-mentioned clear blue solution, and then stirred well, stirred in a 60 ° C water bath, resulting in a light green transparent sol;

[0062] (4) The light-green transparent sol obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com