Preparation method and device of scale-like multifunctional surface microstructure

A microstructure and multi-functional technology, applied in feeding devices, spraying devices, manufacturing tools, etc., can solve the problems of high hardness surface wear, short service life, difficult heat dissipation, etc., to increase the contact area, realize anti-adhesion, reduce The effect of small friction and adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

[0033] The preparation method of fish scale-like multifunctional surface microstructure is as follows:

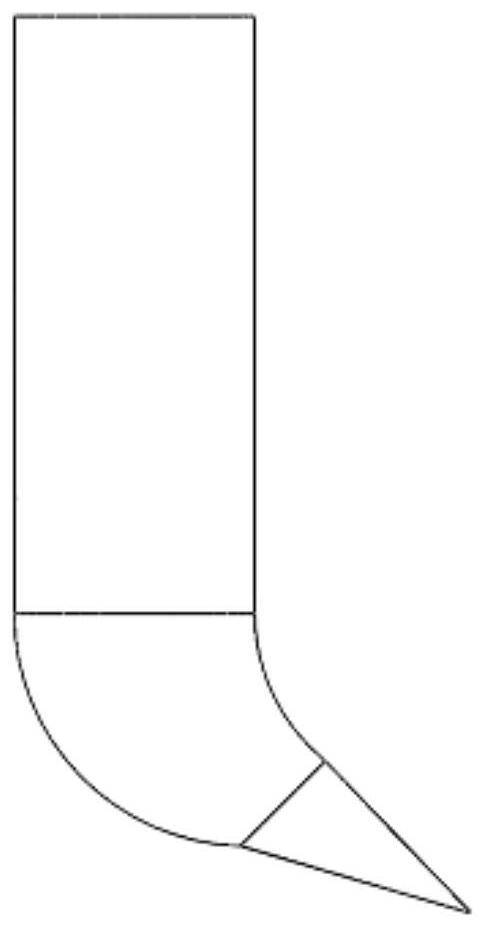

[0034] Step 1, using diamond to make a conical coulter head, such as figure 1 As shown, then the coulter head is sintered and fixed on the handle to make a plowing tool 8; the coulter head is set obliquely, and the apex of the conical shape is set obliquely downward.

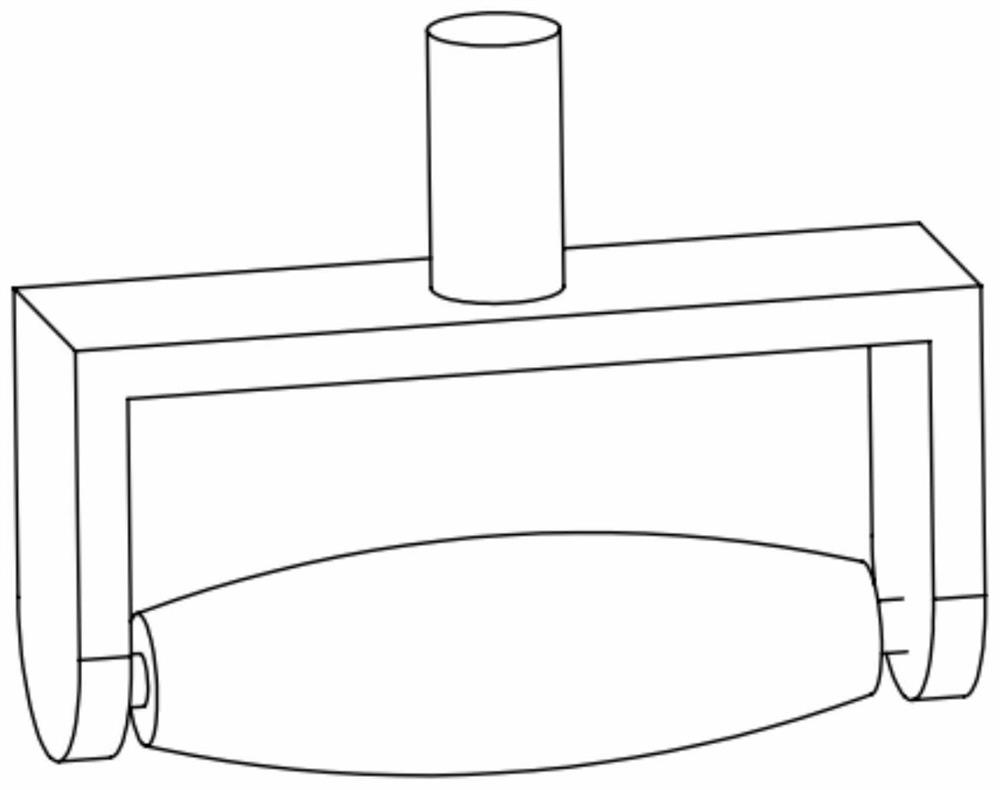

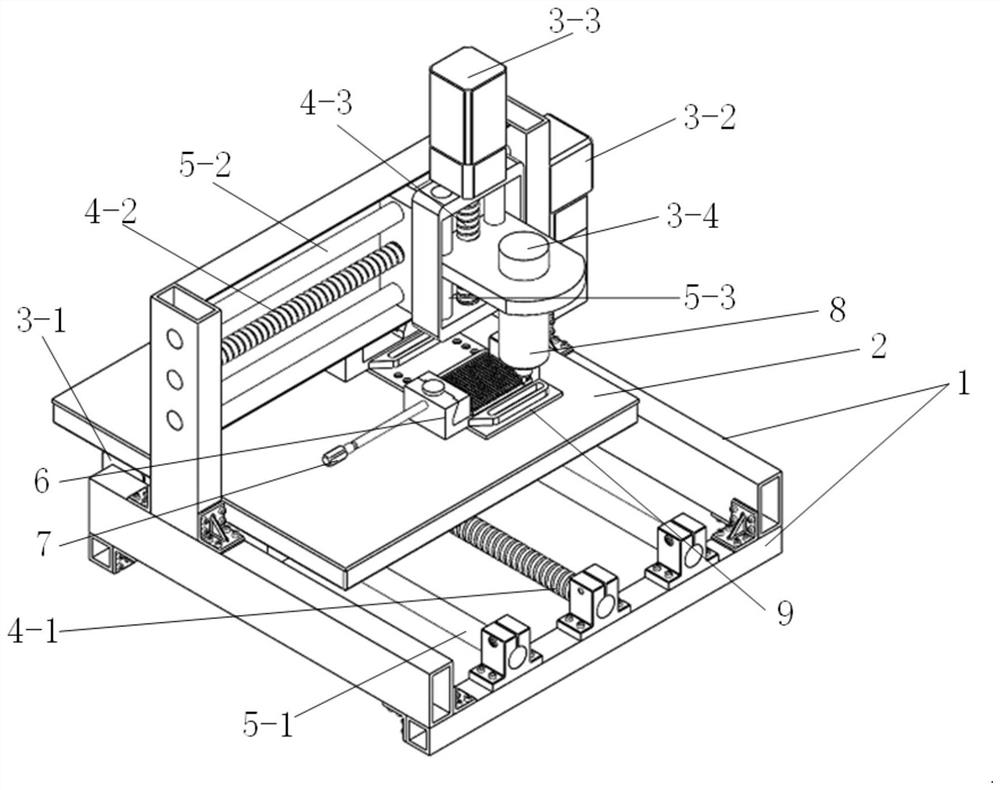

[0035] Step two, such as image 3 As shown, the tool handle of the plowing tool 8 is vertically fixed on the tool installation shaft 3-4, the tool installation shaft 3-4 is vertically fixed on the Z-axis slider, and the workpiece to be processed is clamped on the workpiece holder superior.

[0036] Step 3: drive the X-axis screw 4-1 to rotate through the X-axis transmission motor 3-1, and drive the X-axis slider, the processing plate 2, the workpiece fixture and the workpiece to move along the X-axis sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com