Anti-fouling and anti-adhesion high-strength polyester cable for deep and far seas and preparation method thereof

A high-strength polyester, anti-adhesion technology, applied in the direction of textile cables, textiles and paper, etc., can solve the problems of difficult installation and connection, insufficient strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

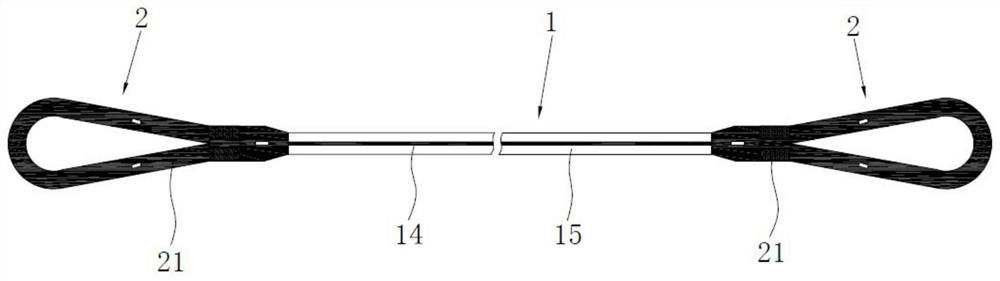

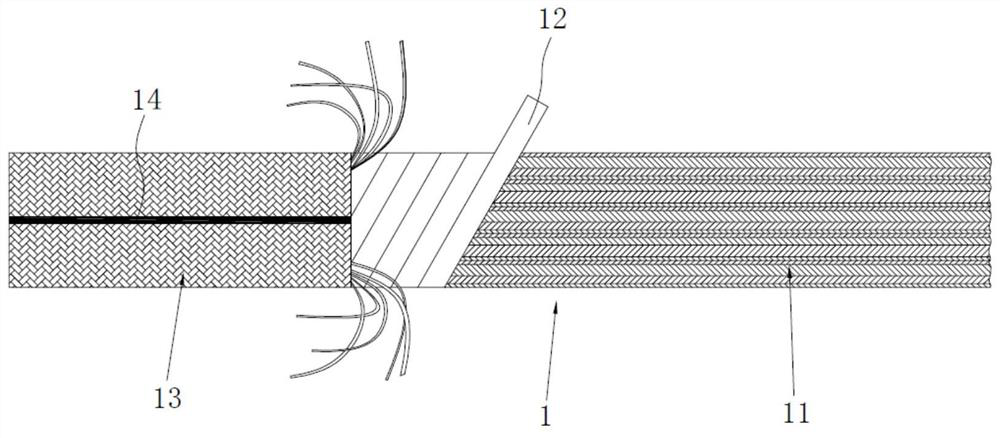

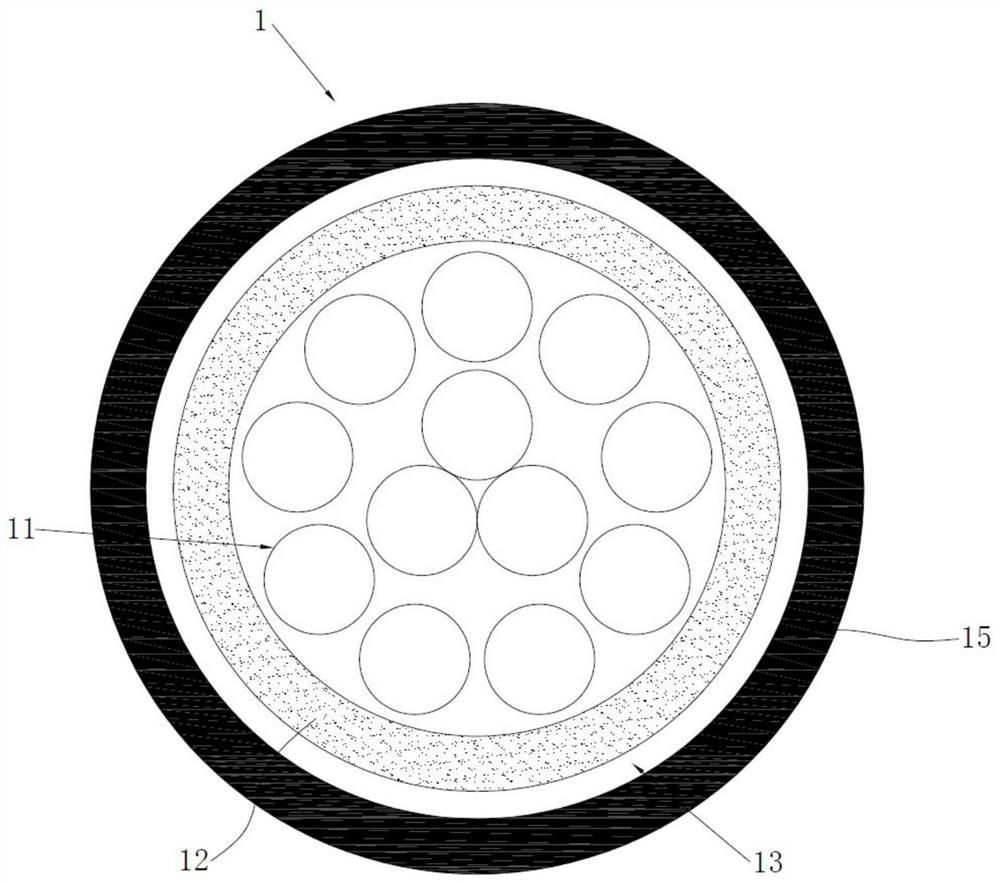

[0056] Such as Figure 1 to Figure 3 Shown is a first embodiment of the anti-fouling and anti-adhesion high-strength polyester cable used in the deep sea of the present invention. Such as figure 1 As shown, it includes a polyester rope body 1 and terminal eye rings 2 located at both ends of the polyester rope body 1. The terminal eye rings 2 are connected to both ends of the polyester rope body 1 by plug-in technology, which is convenient for connection when the cable is used. Such as figure 2 and image 3 As shown, the polyester rope body 1 includes an inner core 11, an anti-sand belt 12 and a braided overcoat 13. The inner core 11 is formed by arranging a plurality of 12-strand ropes in sequence. As an example, it can also be composed of more 12-strand sub-ropes, or more than 12 sub-ropes; the more the number of sub-ropes, the stronger the number of strands; the braided coat 13 is composed of many multi-strand strands Weaving, here weaving 48 4-strand strands with bra...

Embodiment 2

[0059] The present invention is a second embodiment of an anti-fouling and anti-adhesion high-strength polyester cable used in deep sea. Become, braided jacket 13 is woven by 60 8 strands strands.

no. 1 example

[0061] Such as Figure 4 Shown is a first embodiment of the preparation method of a polyester cable used in the deep sea according to the present invention, which specifically includes the following steps:

[0062] S1, making the inner core 11;

[0063] S11. Raw material wire drawing: Stir the raw material evenly and heat it to 250°C to melt it, and then extrude it from the spinneret to form a monofilament. Dry at 70°C and wind up for later use.

[0064] S12. Splicing to make single yarn; the single yarns are bundled into strips and hung on the grid, then pulled to the splicing machine, and the single yarn is twisted clockwise or counterclockwise by the splicing machine to form a single yarn. The single yarn is seawater-grade polyester yarn, and the performance of the single yarn is tested. Among them, during the splicing process, the tension meter on the splicing machine performs tension control to ensure that the minimum breaking load of the cable is 21437KN. In addition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com