Full-automatic poultry claw yellow skin removing machine controlled by PLC

A fully automatic poultry technology, which is applied in the program control, poultry processing, program control and other directions of the sequence/logic controller, can solve the problems of difficult to grasp the peeling time, labor-intensive, inconvenient use, etc., to save labor resources , labor saving, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

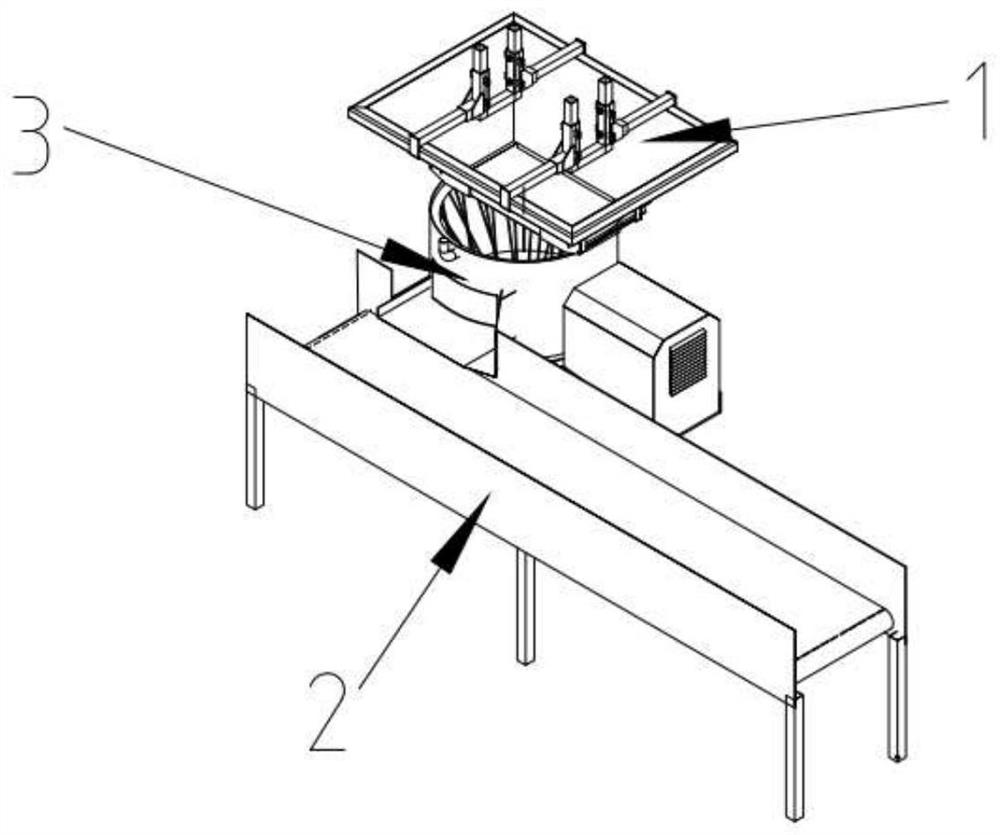

[0032] A PLC-controlled full-automatic poultry claw peeling machine, see figure 1 , including an unloading device 1, a claw machine 3, a transportation unit 2 and a PLC control unit, the PLC control unit is used to remotely control the device, the unloading device 1 is located at the top of the entire system, and there is a punching machine below it. claw machine 3, combined Figure 6 , the outer wall of one side of the claw machine 3 is also provided with a finished product outlet 33, and the outer side of the finished product outlet 33 is provided with a transportation part 2 matched with it, and the unloading device 1, the claw machine 3 and the transportation part 2 are all connected with The PLC control unit is connected to realize the automatic control of the device operation, which greatly saves labor resources, and the PLC control is more stable and reliable.

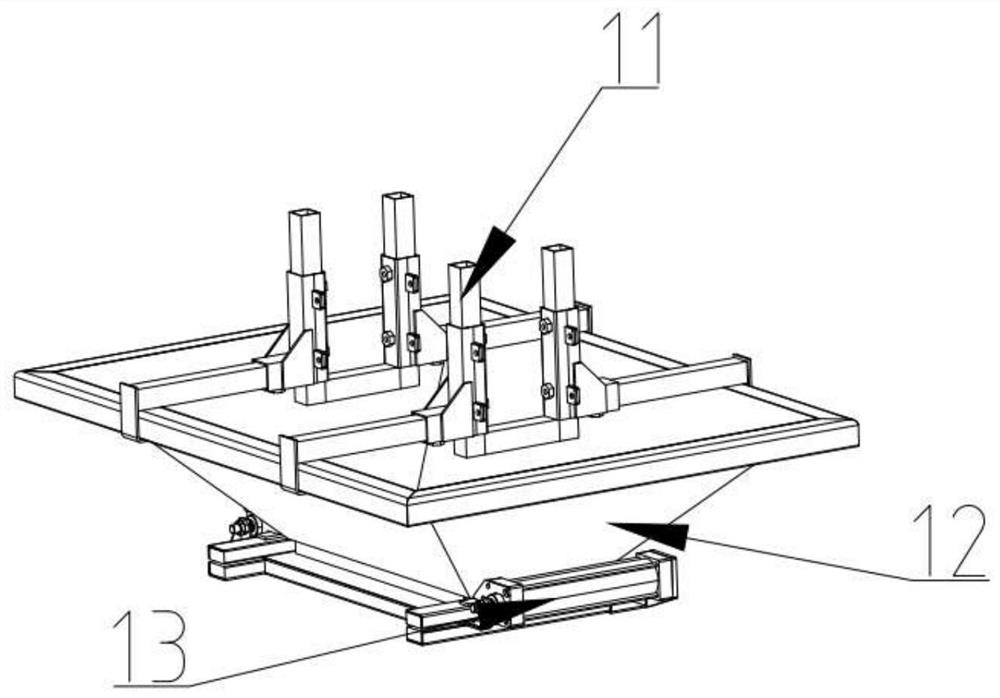

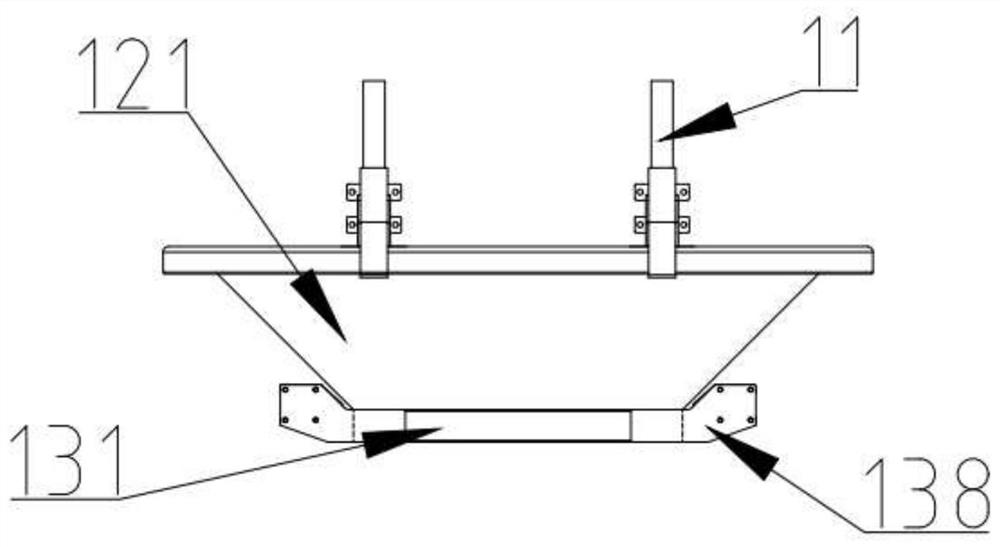

[0033] In this example, see figure 2 , the unloading device 1 includes a hanger 11, a discharge hopper 12 ...

Embodiment 2

[0051] In order to prevent poultry claws from being stuck, the automatic feeding device 13 described in Embodiment 1 needs to set the distance between the baffle plate 134 and the mounting plate 122 to be 15mm. This embodiment provides a new solution without having to reserve a distance.

[0052] see Figure 7 , Figure 8 , in this embodiment, the inner side of the inclined wall 121 on the side close to the installation plate 122 of the discharge hopper 12 is provided with a claw stop plate 127, and the inclined wall 121 is provided with a slot 125, and the outer side of the inclined wall 121 is provided with A power element, the transmission end of the power element is connected with a push-pull rod 126, and the push-pull rod 126 passes through the slot 125 and is connected to the rear of the pawl plate 127, the power element is a push-pull cylinder 124, and the push-pull The gas port of the cylinder 124 is connected to the gas storage tank through a control valve, the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com