Preparation method and application of electrochemical sensor for detecting transgenic soybeans based on double-signal output of gene editing technology

A technology of genetically modified soybeans and gene editing, which is applied in the fields of biochemical equipment and methods, electrochemical variables of materials, and analysis by making materials undergo chemical reactions. High, selective, and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

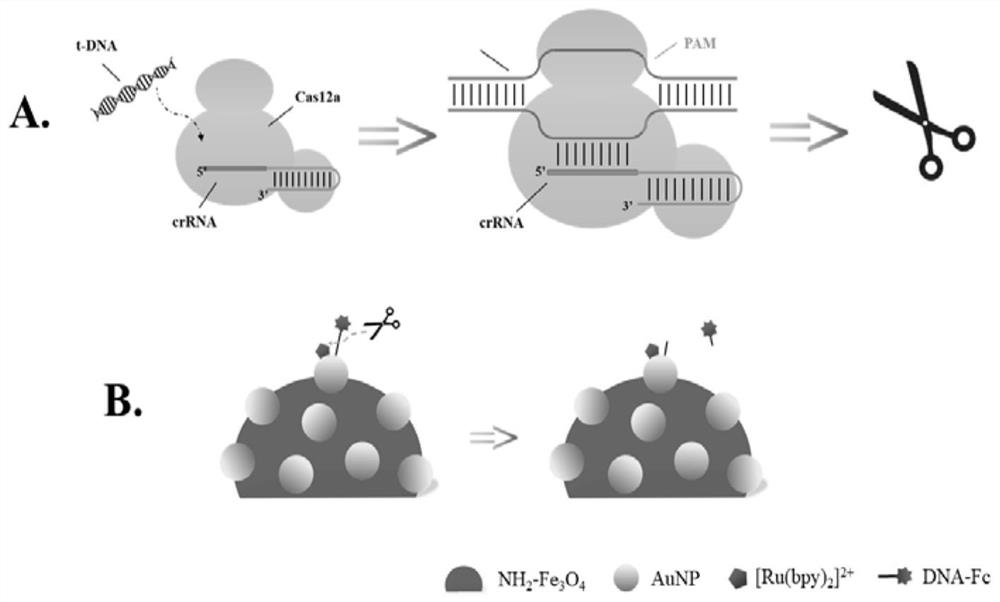

[0038] A method for preparing an electrochemical sensor for detecting transgenic soybeans based on gene editing technology with dual signal output, such as figure 1 shown, including the following steps:

[0039] 1. Magnetic material Fe 3 o 4 Synthesis of @AuNPs

[0040] (1) Add 2.8 g FeCl 3 ·6H 2 O, 7.8 g NH 4 Ac and 0.8 g of sodium citrate were dissolved in 135 mL of ethylene glycol, stirred vigorously at 155 °C for 1 h under nitrogen protection, then transferred to a Teflon-lined stainless steel autoclave, heated at 200 °C for 15 h, and then naturally Cool to room temperature to obtain magnetic beads, wash the magnetic beads with ethanol and ultrapure water several times, and disperse them in 50 mL of ethanol to obtain ferric oxide nanoparticles Fe 3 o 4 NPs;

[0041] (2) Add 45 mL Fe 3 o 4 NPs were mixed with 0.5 mL 3-aminopropyltriethoxysilane (APTES), sonicated for 0.5 hours, stirred at room temperature for 7 hours, magnetically separated, washed, and redispers...

Embodiment 2

[0051]With above-mentioned embodiment 1, its difference is:

[0052] Step 1 Magnetic Material Fe 3 o 4 @AuNPs is synthesizing:

[0053] (1) Add 2.5g FeCl 3 ·6H 2 O, 7.5 g NH 4 Ac and 0.5 g of sodium citrate were dissolved in 150 mL of ethylene glycol, stirred vigorously at 140 °C for 1 h under nitrogen protection, then transferred to a Teflon-lined stainless steel autoclave, heated at 200 °C for 14 h, and then Naturally cool to room temperature to obtain magnetic beads, wash the magnetic beads with ethanol and ultrapure water several times, and disperse them in 50 mL of ethanol to obtain ferric oxide nanoparticles Fe 3 o 4 NPs;

[0054] (2) Add 40 mL Fe 3 o 4 NPs were mixed with 0.4 mL of 3-aminopropyltriethoxysilane (APTES), sonicated for 0.5 hours, stirred at room temperature for 5 hours, magnetically separated, washed, and redispersed in 50 mL of water to obtain aminated Fe 3 o 4 NPs;

[0055] (3) Add 0.6 mL of 0.3 mol / L NaOH solution and 0.5 mL of 80 wt% tetrak...

Embodiment 3

[0061] With above-mentioned embodiment 1, its difference is:

[0062] Step 1 Magnetic Material Fe 3 o 4 @AuNPs is synthesizing:

[0063] (1) Add 3.0 g FeCl 3 ·6H 2 O, 8.0 g NH 4 Ac and 1.0 g of sodium citrate were dissolved in 150 mL of ethylene glycol, stirred vigorously at 170 °C for 1 h under nitrogen protection, then transferred to a Teflon-lined stainless steel autoclave, heated at 200 °C for 16 h, and then Naturally cool to room temperature to obtain magnetic beads, wash the magnetic beads with ethanol and ultrapure water several times, and disperse them in 50 mL of ethanol to obtain ferric oxide nanoparticles Fe 3 o 4 NPs;

[0064] (2) Add 50 mL Fe 3 o 4 NPs were mixed with 0.6 mL 3-aminopropyltriethoxysilane (APTES), sonicated for 0.5 hours, stirred at room temperature for 8 hours, magnetically separated, washed, and redispersed in 50 mL of water to obtain aminated Fe 3 o 4 NPs;

[0065] (3) Add 1.0 mL of 0.1 mol / L NaOH solution and 0.7 mL of 80 wt% tetrahy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com