Engineering blasting foundation detonator capable of improving safety

A basic detonator and safety technology, applied in blasting cylinders, offensive equipment, fuzes, etc., can solve the problems of less safety considerations, improve the intrinsic safety of engineering detonators, and hidden safety hazards, and improve anti-interference and safety. , The effect of improving anti-explosion characteristics and improving storage life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing of description, the present invention will be further described.

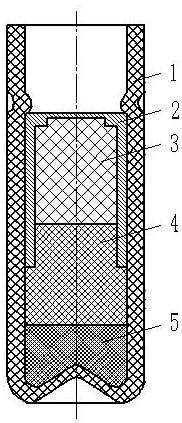

[0013] combine figure 1 , a basic detonator for engineering blasting with improved safety, which is used to make an engineering electric detonator after being assembled with an electric ignition head or used alone as an engineering flame detonator, including a tube shell 1, a reinforcing cap 2, a priming charge 3, and a first-stage blasting detonator. Explosives 4 and secondary high explosives 5, one end of the reinforced cap 2 is closed as the input end of the detonator, and the other end is open. and the primary high explosive 4 are sequentially loaded in the shell 1 from bottom to top, and the reinforcing cap 2 suppressing the primary explosive 3 is reassembled into the shell 1, so that the top of the primary high explosive 4 is pressed into the cavity of the reinforcing cap 2 , and in contact with the priming charge 3, and then the reinforcing cap 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com