Post-processing treatment device for environment-friendly fabric and method for drying environment-friendly fabric through post-processing treatment device

A processing device and fabric technology, applied in the direction of dry cargo handling, dry solid materials, dry gas arrangement, etc., can solve the problems of inability to arrange fibers, poor fabric processability, etc., to improve flow speed, reduce waste, improve The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

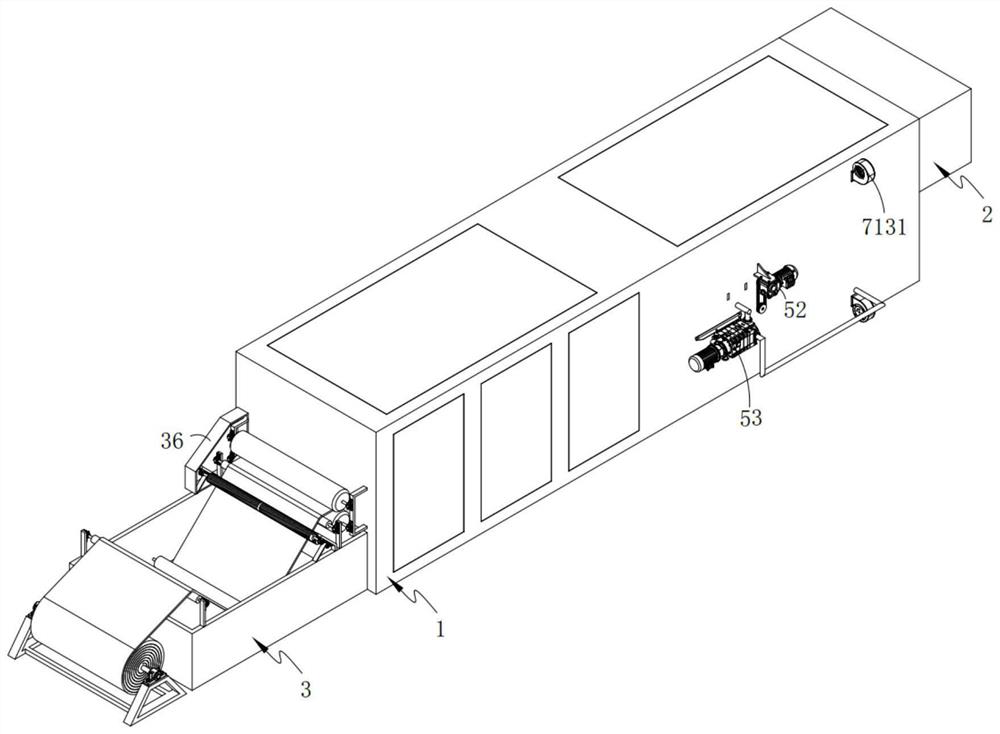

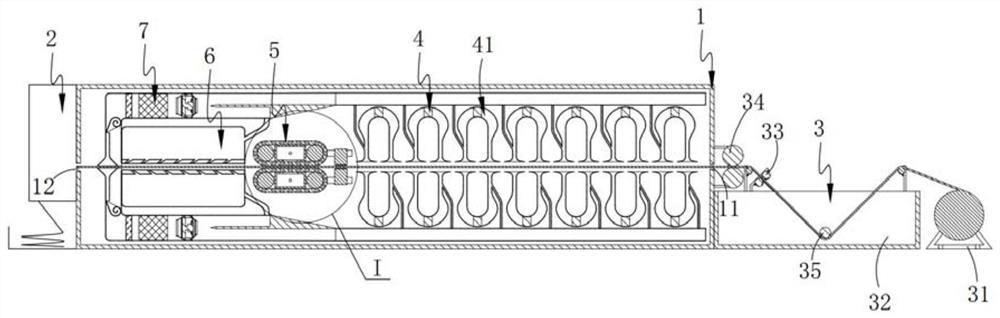

[0061] Such as Figure 1-5 As shown, a post-processing device for environmentally friendly fabrics includes a box body 1, a traction system 2 located at one end of the box body 1, and a sizing system 3 located at the other end of the box body 1, and the two ends of the box body 1 are respectively set There is a feed port 11 and a discharge port 12, and the traction system 2 includes a drive motor, a drive chain and some discharge rollers; it also includes:

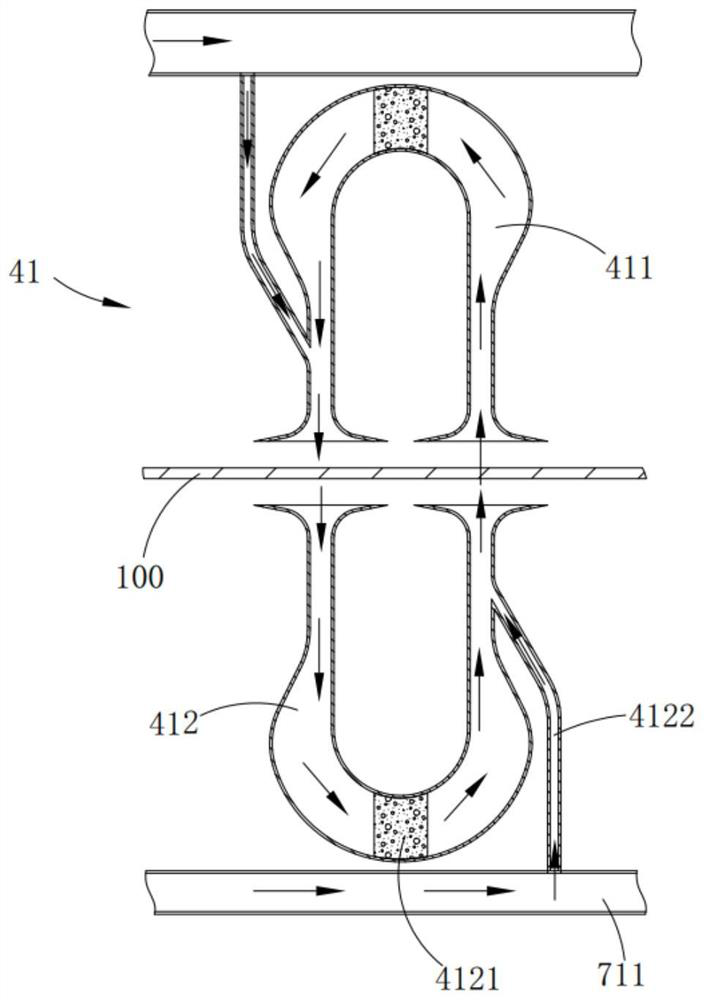

[0062] A pre-drying system 4, the pre-drying system 4 is arranged at one end of the feed port 11 in the box body 1, and includes multiple sets of linearly arranged pre-drying units 41, the pre-drying units 41 include The upper drying channel 411 and the corresponding lower drying channel 412, the upper drying channel 411 and the lower drying channel 412 form a circular loop; the fabric 100 passes between the upper drying channel 411 and the lower drying channel 412 between;

Embodiment 2

[0093] The method for drying an environmentally-friendly fabric by using a post-processing device for an environmentally-friendly fabric described in the technical solution of the first embodiment above includes the following steps:

[0094] Step 1, the fabric 100 reel is fixed, the fabric 100 reel to be sized is fixed on the unwinding support 31, and the traction system 2 is used to pull the fabric 100 forward;

[0095] Step 2, sizing, when the fabric 100 passes through the sizing tank 32, the surface of the fabric 100 is subjected to sizing treatment; the fabric 100 is flattened by the flattening roller 331, and the fabric 100 is extruded by the squeeze roller arranged behind the flattening roller 331 Apply excess size while pressing fiber debris into the fabric 100 to form fiber nubs;

[0096] Step 3, pre-drying treatment, the sized fabric 100 passes through the pre-drying system 4, and uses the circuit-shaped pre-drying unit 41 to quickly remove 70%-80% of the moisture in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com