Method for controlling main steam desuperheating water of unit

A control method and technology of desuperheating water, which are applied in the control of superheated temperature, steam superheating, steam generation, etc., can solve the problems of overheating of the main steam temperature and the failure of automatic tracking of the desuperheating water valve, so as to avoid the tripping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

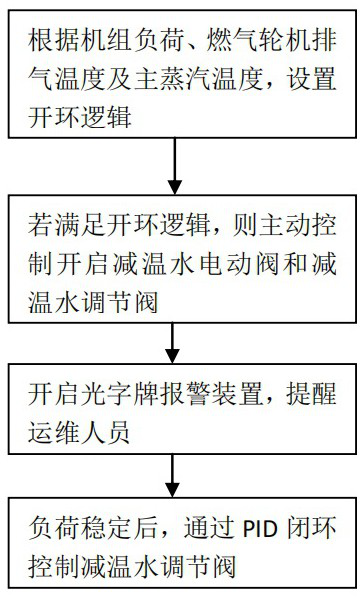

[0030] Such as figure 1 As shown, a control method of the main steam desuperheating water of the unit, the control method of the main steam desuperheating water of the unit includes the following steps:

[0031] S1: When the unit starts, set the open-loop logic according to the unit load, gas turbine exhaust temperature and main steam temperature;

[0032] S2: Determine whether the condition of the unit meets the open-loop logic, and if so, actively control the desuperheating water electric valve and desuperheating water regulating valve according to the open-loop logic;

[0033] S3: After triggering the open-loop logic, turn on the light plate alarm device to remind the operation and maintenance personnel;

[0034] S4: After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com