Four-foot hollow square block with inclined side walls and construction method thereof

A hollow block and hollow technology, applied in coastline protection and other directions, can solve the problems of block jumping instability, waste of resources, affecting the safety of project operation, etc., so as to improve the ability to resist wind and waves, avoid waste of resources, and avoid jumping and instability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings.

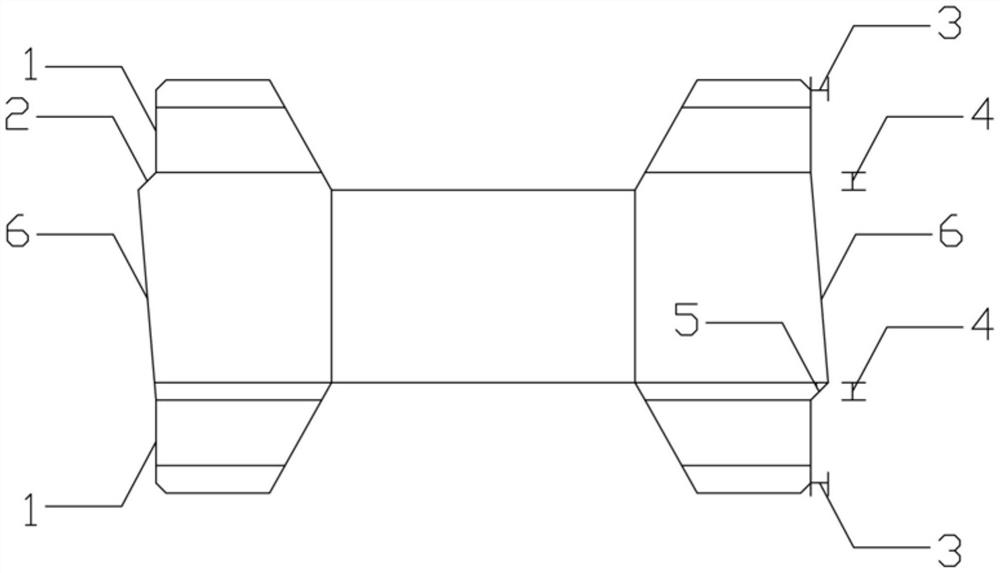

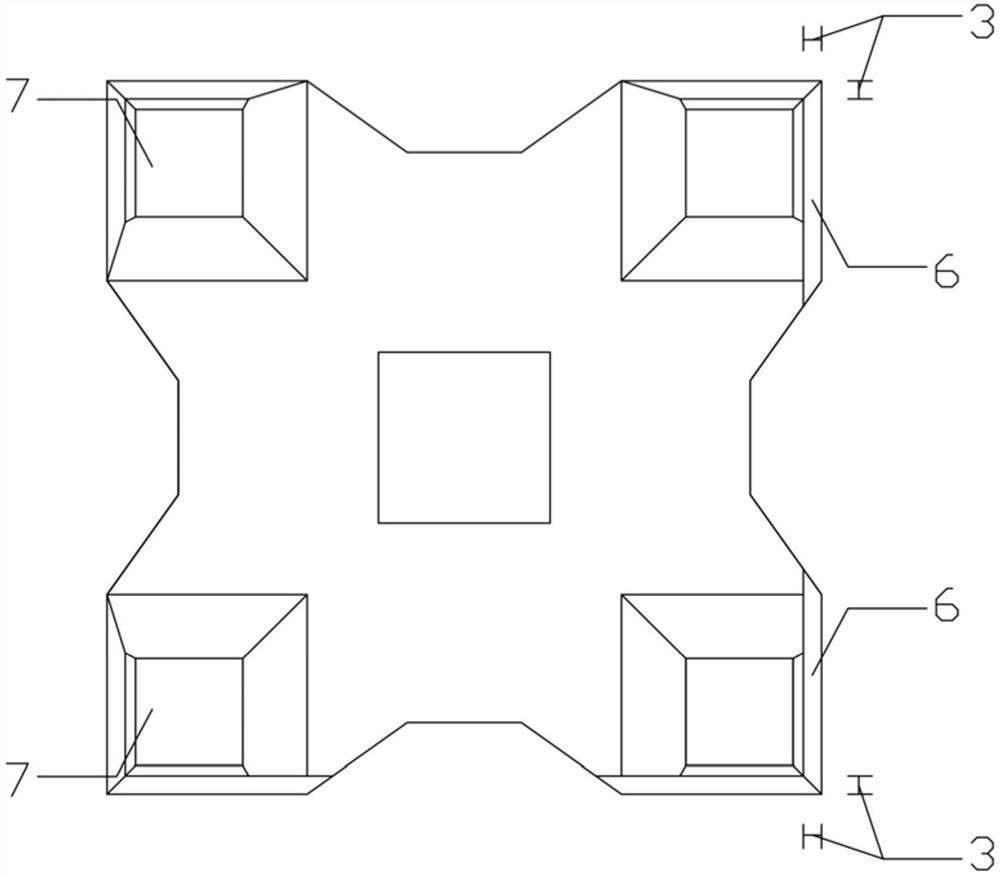

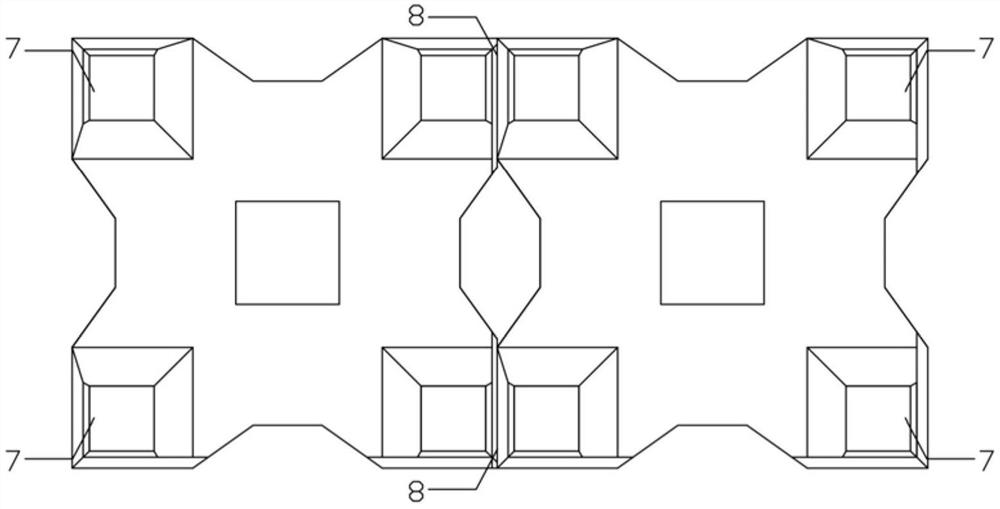

[0027] Refer Figure 1 ~ 8 One side wall is inclined with a four-foot hollow square, including a block, and the central portion of the block is provided with a venting hole of the upper and lower communication, and the square is concave, and the following four angles in the block. There is a suspended foot 7, each of which is provided with an outer side of the adjacent block, and the outer side is provided with an inner segment 1, and the adjacent two four-foot hollow squares At the time, the inside of the two four-foot hollow squares is formed to prevent the protective gap 8 for preventing the crushing of the flush. The sidewall of the projection of the projection of the block is made into a slope or a beveled surface or a slope 6 including a slope.

[0028] Further, the lower section of the outer side is downwards 2, and the upper section of the outer side is an internal se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com