A kind of generator set fuel heating start control system and method

A start-up control and generator set technology, which is applied in the direction of engine start-up, charging system, engine components, etc., can solve the problems of low operating efficiency, poor stability, flexibility and reliability, difficulty in use and maintenance of power generation operations, etc., and achieve improvement Stability and environmental adaptability, low cost of equipment operation and maintenance, and the effect of reducing energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the construction of the technical means, creation features, achievement goals and effects of the present invention, the present invention will be further described below with reference to specific embodiments.

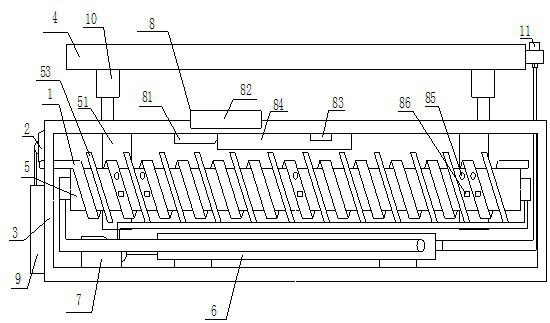

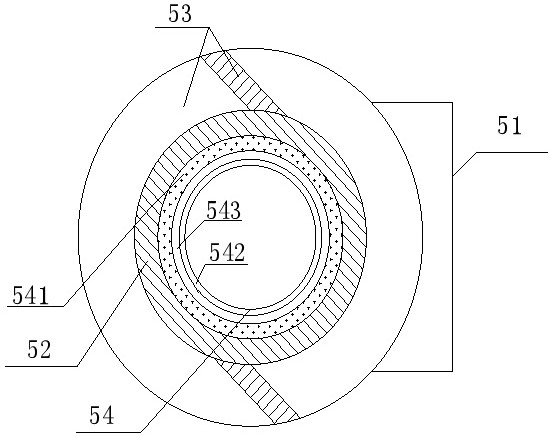

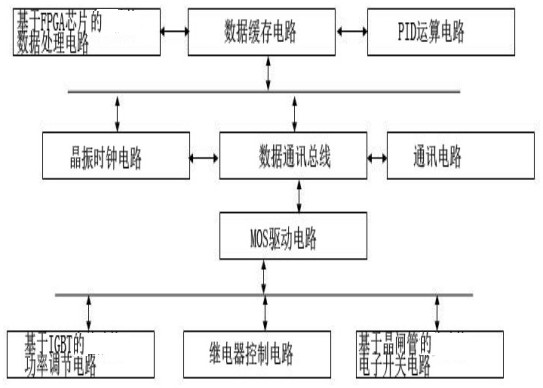

[0026] see figure 1, a fuel heating start control system for a generator set, comprising a fuel supply pipe 1, a booster pump 2, a load frame 3, a load bracket 4, a heat exchange tube 5, an air vortex tube 6, a booster fan 7, a start control Circuit 8, wherein the bearing frame 3 is a frame structure with a rectangular axial section, the bearing bracket 4 is a plate-shaped structure whose axis is parallel to the axis of the bearing frame 3, and is connected to the upper end surface of the bearing frame 3, and the heat exchange tube 5 is embedded in the bearing frame 3 and distributed coaxially with the bearing frame 3, at least one fuel supply pipe 1 covers the outside of the heat exchange tube 5 and is distributed along the axis of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com