A kind of composite modifier for deep modification of eutectic silicon and preparation method thereof

A composite modifier and composite modification technology, applied in the field of cast aluminum alloys, can solve the problems of no obvious eutectic silicon morphology, limiting the improvement of the plasticity of Al-Si alloy cast aluminum alloys, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

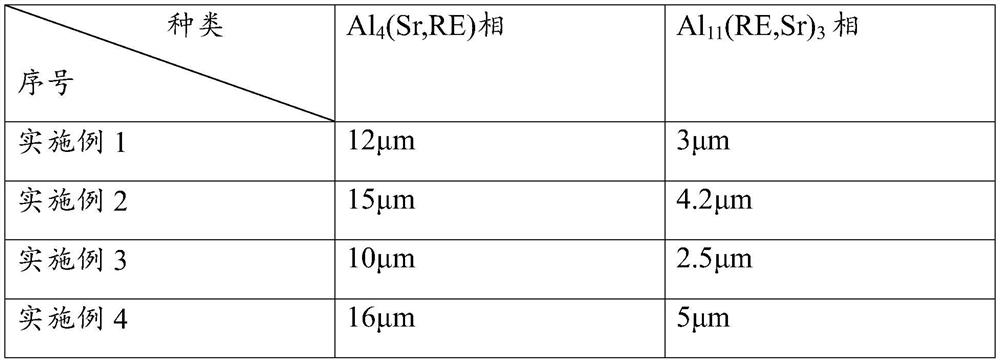

Embodiment 1

[0039] This implementation provides a composite modifier for deep modification of eutectic silicon, which includes 5.0% Sr, 9.0% Ce and 86.0% Al in terms of mass percentage, and inevitable impurity elements;

[0040] The compound modificator is prepared by the following method:

[0041] S1: put commercially pure aluminum into the melting furnace, raise the temperature to 750°C, and after it is completely melted, add a covering agent of 0.02% of the mass of the melt, and then press Al-10Sr and Al-20Ce into the melt with a bell jar made of Ti;

[0042] S2: Raise the temperature to 850°C. After the raw materials are completely melted, take a sample to test the components; then pass high-purity argon gas with a purity of 99.99% into the melt for 10 minutes;

[0043] S3: After the melt is left to stand for 30 minutes, the slag is removed, and cast to a semi-continuous casting machine to prepare a cylindrical ingot with a diameter of 110 mm;

[0044] S4: After the cast ingot is coo...

Embodiment 2

[0046] This implementation provides a composite modifier for deep modification of eutectic silicon, which includes 8.0% Sr, 15% La and 77.0% Al in terms of mass percentage, and unavoidable impurity elements;

[0047] The compound modificator is prepared by the following method:

[0048] S1: put commercially pure aluminum into the melting furnace, raise the temperature to 800°C, after it is completely melted, add 0.02% covering agent of the mass of the melt, and then use a bell jar made of Ti to press metal Sr and metal La into the melt;

[0049] S2: Raise the temperature to 900°C, and after the raw materials are completely melted, take samples to test the components; then pass high-purity argon gas with a purity of 99.99% into the melt for 10 minutes;

[0050] S3: After the melt is left to stand for 15 minutes, the slag is removed, and cast to a semi-continuous casting machine to prepare a cylindrical ingot with a diameter of 210 mm;

[0051] S4: After the ingot is cooled, th...

Embodiment 3

[0053] This implementation provides a composite modifier for deep modification of eutectic silicon, which includes 6.5% of Sr, 6.0% of Ce, 6.0% of La and 86.0% of Al in terms of mass percentage, and unavoidable impurity elements ;

[0054] The compound modificator is prepared by the following method:

[0055] S1: put industrial pure aluminum into the melting furnace, raise the temperature to 750°C, after it is completely melted, add a covering agent of 0.02% of the mass of the melt, and then use a bell jar made of Ti to press metal Sr, Al-20Ce, Al-15La into the melt middle;

[0056] S2: The temperature is raised to 880° C., and after the raw materials are completely melted, the components are sampled and tested; then high-purity argon gas with a purity of 99.99% is introduced into the melt for 15 minutes;

[0057] S3: After the melt was allowed to stand for 20 minutes, the slag was removed, and cast into a semi-continuous casting machine to prepare a cylindrical ingot with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com