Glaze firing process method for ceramic ware

A process method and glaze firing technology, applied in the field of ceramic ware processing, can solve the problems of lack of health care performance and poor use experience, and achieve high glaze gloss, good use experience, good wear resistance and thermal shock resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

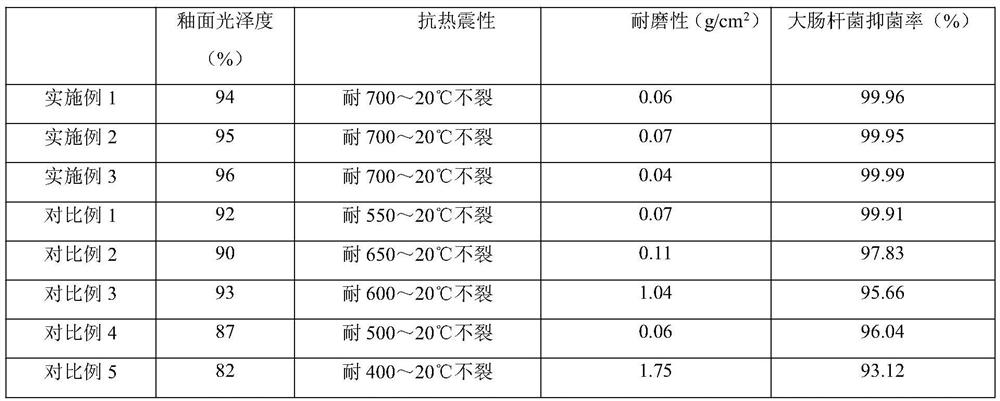

Examples

Embodiment 1

[0033] A ceramic vessel glaze firing process method, firstly apply the bottom glaze on the surface of the ceramic green body, glaze firing at 1100°C for 140 minutes, then apply top glaze on the surface of the bottom glaze, and glaze firing at 700°C for 70 minutes; wherein, the bottom glaze It is obtained by ball milling the following components: 100kg of silicon dioxide, 30kg of coal gangue powder, and 25kg of potassium fluoroaluminate; the surface glaze is prepared by the following method:

[0034] (1) First add 1kg tourmaline powder, 0.1kg gallium nitride powder and 3kg heat-treated liquid polyacrylonitrile into 5kg solvent, stir and mix well, and calcinate at 1800°C for 6 hours under nitrogen atmosphere to obtain composite graphene;

[0035] (2) Carry out polyacrylamide modification to composite graphene then, obtain modified composite graphene;

[0036] (3) 14kg of medical stone powder is modified by gamma-(2,3-epoxypropoxy)propyltrimethoxysilane to obtain modified medical...

Embodiment 2

[0051] A ceramic vessel glaze firing process method, firstly apply the bottom glaze on the surface of the ceramic green body, glaze firing at 1200°C for 120 minutes, then apply top glaze on the surface of the bottom glaze, and glaze firing at 750°C for 50 minutes; wherein, the bottom glaze It is obtained by mixing and ball milling the following components: 100kg of silicon dioxide, 35kg of coal gangue powder, and 20kg of potassium fluoroaluminate; the surface glaze is prepared by the following method:

[0052] (1) First add 1kg tourmaline powder, 0.2kg gallium nitride powder and 2kg heat-treated liquid polyacrylonitrile into 7kg solvent, stir and mix well, and calcinate at 1700°C for 8 hours under nitrogen atmosphere to obtain composite graphene;

[0053] (2) Carry out polyacrylamide modification to composite graphene then, obtain modified composite graphene;

[0054] (3) 12kg of medical stone powder is modified by gamma-(2,3-epoxypropoxy)propyltrimethoxysilane to obtain modif...

Embodiment 3

[0069] A ceramic vessel glaze firing process method, firstly apply the bottom glaze on the surface of the ceramic green body, glaze firing at 1150°C for 130 minutes, then apply top glaze on the surface of the bottom glaze, and glaze firing at 720°C for 60 minutes; wherein, the bottom glaze It is obtained by mixing and ball milling the following components: 100kg of silicon dioxide, 32kg of coal gangue powder, and 22kg of potassium fluoroaluminate; the surface glaze is prepared by the following method:

[0070] (1) First add 1kg tourmaline powder, 0.15kg gallium nitride powder and 2.5kg heat-treated liquid polyacrylonitrile into 6kg solvent, stir and mix well, and calcinate at 1750°C for 7 hours under nitrogen atmosphere to obtain composite graphene ;

[0071] (2) Carry out polyacrylamide modification to composite graphene then, obtain modified composite graphene;

[0072] (3) 13kg of medical stone powder is modified by gamma-(2,3-epoxypropoxy)propyltrimethoxysilane to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com