A cooling method for controlling side bending deformation of marine L-shaped steel after rolling

A cooling method and technology on the control side, applied in the direction of metal rolling, metal rolling, temperature control, etc., to achieve the effects of simple operation, improved uniformity, and good achievability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Cooling method for controlling the deformation of the side bend after marine L-shaped steel, including the steps of:

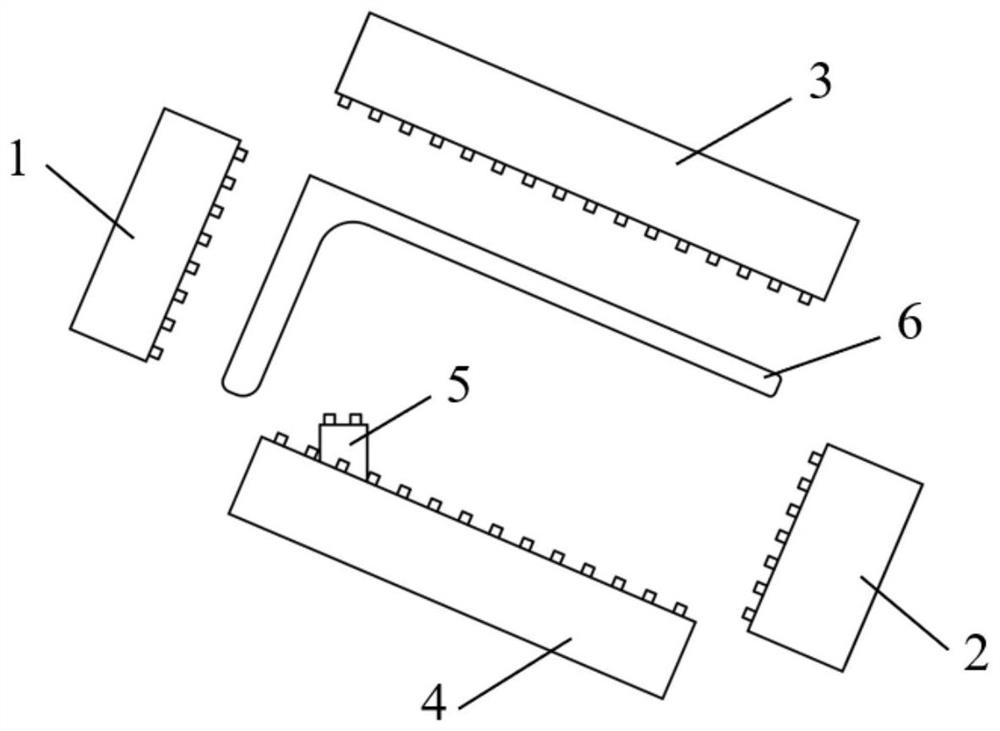

[0022] Step 1: After the billet L-type steel blank is completed by the billet, the ferrule L-type steel 6 after the final rolling is obtained, and the rapid cooling treatment is subsequently cooled, and different intensities are applied to the three parts of the end-rolled ship L-steel 6. Cool, such as figure 1 As shown, the nozzle of the I No. 1 and II water box 2 is water-cooled on both sides of the panel, and the nozzle of the III water box 3 and IV water tank 4 is water-cooled to water cooling on both sides of the web, using the V-tank 5 The nozzle is water-cooled to the R angular position, the cooling strength of: the cooling strength of the R angle position> The cooling strength of the position of the panel is positioned> The cooling strength of the position of both sides of the web, the overall cooling rate of the marine L-steel is 62 ° C / s, coolin...

Embodiment 2

[0032] Cooling method for controlling the deformation of the side bend after marine L-shaped steel, including the steps of:

[0033] Step 1: After completing the finished rolling, after the billet is finished, it is obtained from the end-rolled marine L-steel, which is subsequently cooled, and different intensity cooling is applied to the three parts of the end-rolled ship L-type steel. The cooling mode is in Example 1, the cooling strength of: the cooling strength of the R angular position> The cooling strength of both sides of the panel> The cooling strength of both sides of the web, the overall cooling rate of the marine L-steel is 50 ° C / s, cooling time For 6S, the cold temperature is 620 ° C, which is obtained from the end of the ship.

[0034] Step 2: After the end of the boat L-shaped steel, the temperature of the return temperature is 711 to 719 ° C, and then the L-type steel enters the cold bed and cold to room temperature.

[0035] The chemical composition of the marin...

Embodiment 3

[0043] Cooling method for controlling the deformation of the side bend after marine L-shaped steel, including the steps of:

[0044]Step 1: After completing the finished rolling, after the billet is finished, it is obtained from the end-rolled marine L-steel, which is subsequently cooled, and different intensity cooling is applied to the three parts of the end-rolled ship L-type steel. The cooling mode is in Example 1, the cooling strength of: the cooling intensity of the C-angle position> The cooling strength of the position of the panel, the cooling strength of both sides of the web, the overall cooling rate of the marine L-steel is 70 ° C / s, cooling time For 3s, the cold temperature is 670 ° C, which is obtained from the end of the ship.

[0045] Step 2: After the end of the endless ship L-type steel, the temperature of the return temperature is 754 to 765 ° C, and then the L-steel enters the cold bed and cools to room temperature.

[0046] The chemical composition of the mar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com