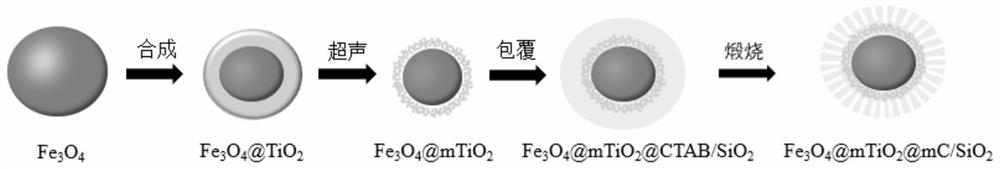

Preparation method and application of magnetic mesoporous titanium dioxide composite material

A technology of mesoporous titanium dioxide and composite materials, applied in chemical instruments and methods, oxidized water/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as mechanical instability and inconvenient recycling of catalysts , to achieve the effects of promoting adsorption and enrichment, good stability and durability, and increasing the generation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

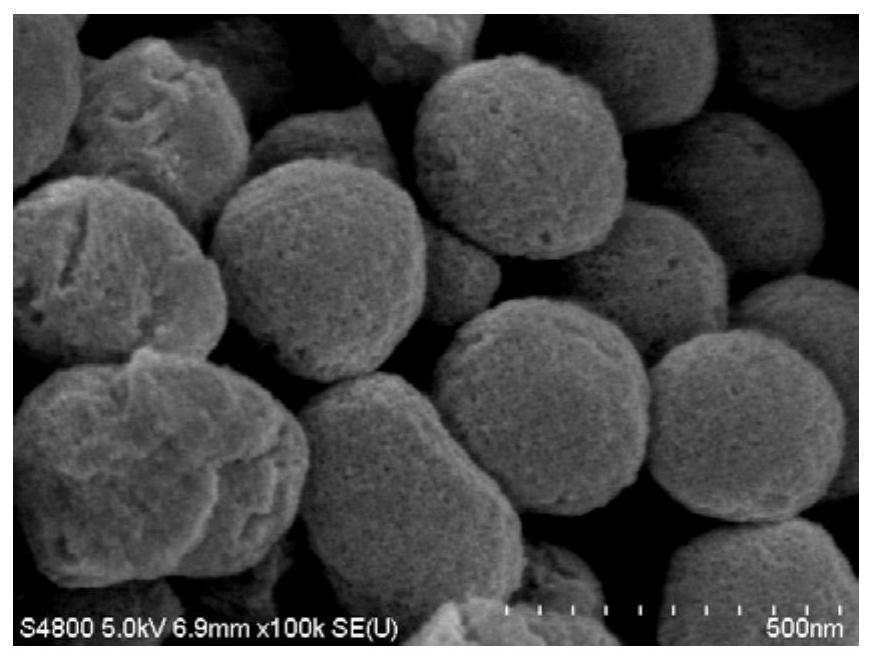

Embodiment 1

[0086] 3.25g of FeCl 3 ·6H 2 The sodium acetate (NaAc) of O, 6.0g and the sodium citrate of 1.3g are dissolved in the ethylene glycol solution of 80mL, after sonication 1h, obtain the FeCl-containing 3 The solution. will contain FeCl 3 The solution was poured into a Teflon-lined stainless steel autoclave with a capacity of 100 mL, heated at 200 °C for 10 h, and then cooled to room temperature to obtain Fe 3 o 4 Magnetite particles. Will Fe 3 o 4 The magnetite particles were washed three times with deionized water and ethanol, respectively, and dispersed in 50 mL of ethanol to obtain Fe 3 o 4 Ethanol dispersion of particles.

[0087] Dilute 3.0mL to a concentration of 0.05gmL -1 Fe 3 o 4 The ethanol dispersion of the particles was added into a three-neck round bottom flask, and the concentration of 100mL of ethanol and 0.4mL of ammonia water of 28wt% was added successively to obtain an Fe-containing 3 o 4 solution of particles. Then, in the state of magnetic stir...

Embodiment 2

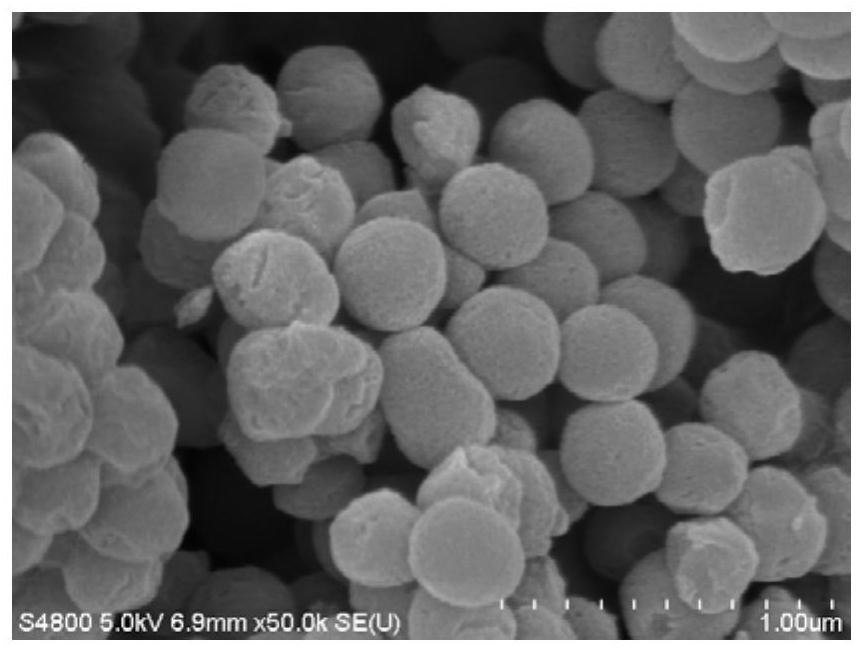

[0092] 3.25g of FeCl 3 ·6H 2 The sodium acetate (NaAc) of O, 6.0g and the sodium citrate of 1.3g are dissolved in the ethylene glycol solution of 80mL, after sonication 1h, obtain the FeCl-containing 3 The solution. will contain FeCl 3 The solution was poured into a Teflon-lined stainless steel autoclave with a capacity of 100 mL, heated at 200 °C for 10 h, and then cooled to room temperature to obtain Fe 3 o 4 Magnetite particles. Will Fe 3 o 4 The magnetite particles were washed three times with deionized water and ethanol, respectively, and dispersed in 50 mL of ethanol to obtain Fe 3 o 4 Ethanol dispersion of particles.

[0093] Dilute 3.0mL to a concentration of 0.05gmL -1 Fe 3 o 4 The ethanol dispersion of the particles was added into a three-neck round bottom flask, and the concentration of 100mL of ethanol and 0.4mL of ammonia water of 28wt% was added successively to obtain an Fe-containing 3 o 4 solution of particles. Then, in the state of magnetic stir...

Embodiment 3

[0098] 3.25g of FeCl 3 ·6H 2 The sodium acetate (NaAc) of O, 6.0g and the sodium citrate of 1.3g are dissolved in the ethylene glycol solution of 80mL, after sonication 1h, obtain the FeCl-containing 3 The solution. will contain FeCl 3 The solution was poured into a Teflon-lined stainless steel autoclave with a capacity of 100 mL, heated at 200 °C for 10 h, and then cooled to room temperature to obtain Fe 3 o 4 Magnetite particles. Will Fe 3 o 4 The magnetite particles were washed three times with deionized water and ethanol, respectively, and dispersed in 50 mL of ethanol to obtain Fe 3 o 4 Ethanol dispersion of particles.

[0099] Dilute 3.0mL to a concentration of 0.05gmL -1 Fe 3 o 4 The ethanol dispersion of the particles was added into a three-neck round bottom flask, and the concentration of 100mL of ethanol and 0.4mL of ammonia water of 28wt% was added successively to obtain an Fe-containing 3 o 4 solution of particles. Then, in the state of magnetic stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com