Conveyor belt longitudinal damage vibration sensing method based on infrared computer vision

A technology of computer vision and conveyor belts, applied in computer parts, calculation, neural learning methods, etc., can solve the problems of easy interference of mathematical models, semi-contact, poor practicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

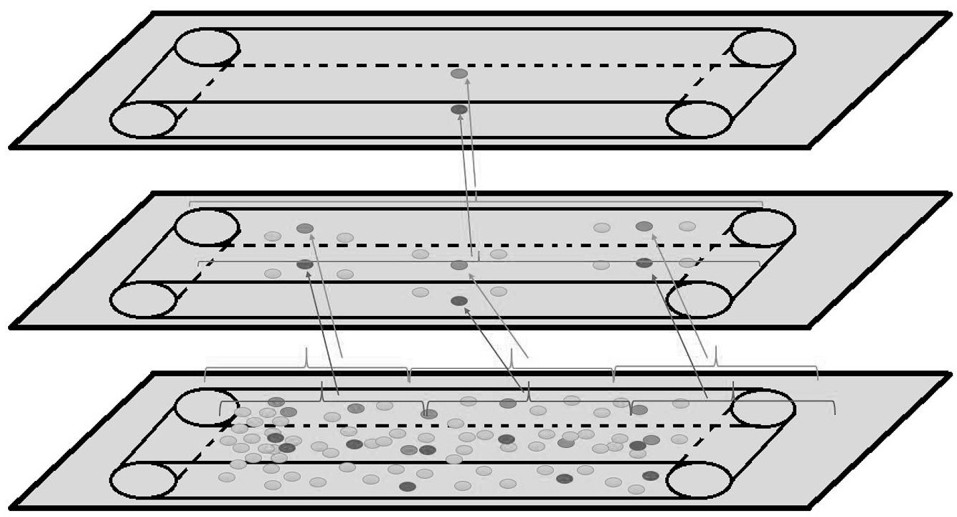

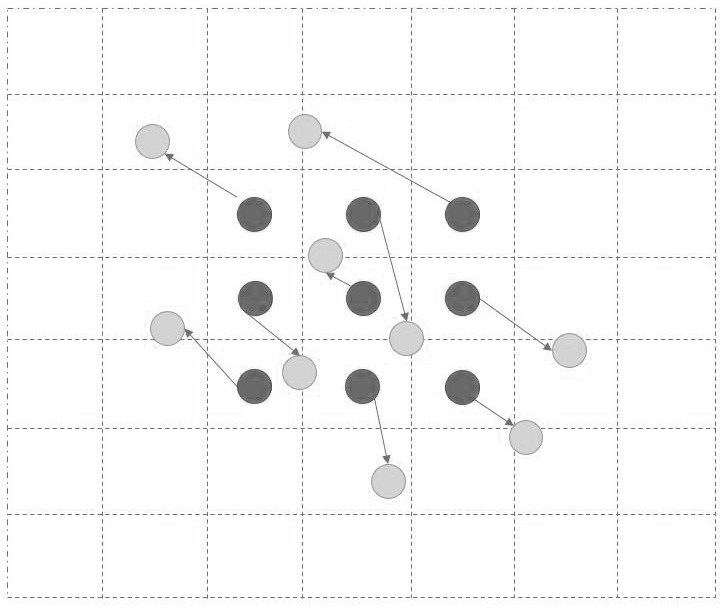

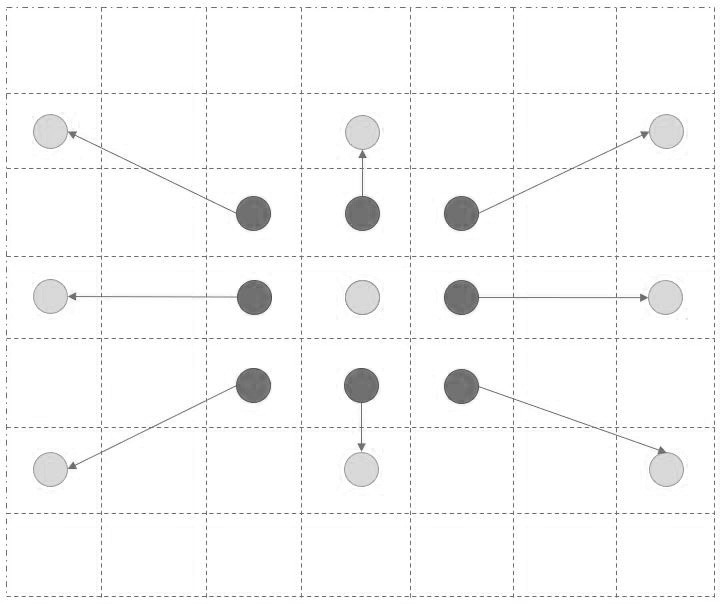

[0029] Such as Figure 1 to Figure 7 Shown, the present invention a kind of conveyer belt longitudinal damage vibration perception method based on infrared computer vision, comprises the following steps:

[0030] Step 1: Build an image data set: set up a high-speed camera above the mine conveyor belt to collect tiny vibration images of the conveyor belt in the normal state, wear state, scratch state, and tear state, and store them on the tower server. The data set is used to initially train the convolutional neural network, and another part of the data set is used to further train the convolutional neural network;

[0031] Step 2: Use the convolutional neural network with variable convolution kernel to train and test the vibration frequency signals of the mining conveyor belt in the normal state, worn state, scratched state, and torn state respectively, and obtain the initially trained convolutional neural network. The internet;

[0032] Step 3: Apply the initially trained c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com