Internet of Things monitoring method and system for agricultural machinery manufacturing

A network monitoring and agricultural mechanism technology, applied in transmission systems, electrical components, etc., can solve problems such as intelligence, low automation, energy waste, and environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] In view of the shortcomings in the prior art, one or more embodiments of the present disclosure provide an IoT monitoring method for agricultural machinery manufacturing, which applies IoT technology to the agricultural machinery manufacturing industry. According to the process requirements and data characteristics of the agricultural machinery manufacturing industry, Collect and process the real-time data of the agricultural machinery manufacturing Internet of Things, carry out the Internet of things monitoring of agricultural machinery manufacturing, and realize the online monitoring and management of the agricultural machinery production process through the collection and analysis of real-time production data.

[0083] According to an aspect of one or more embodiments of the present disclosure, there is provided an IoT monitoring method for agricultural machinery manufacturing.

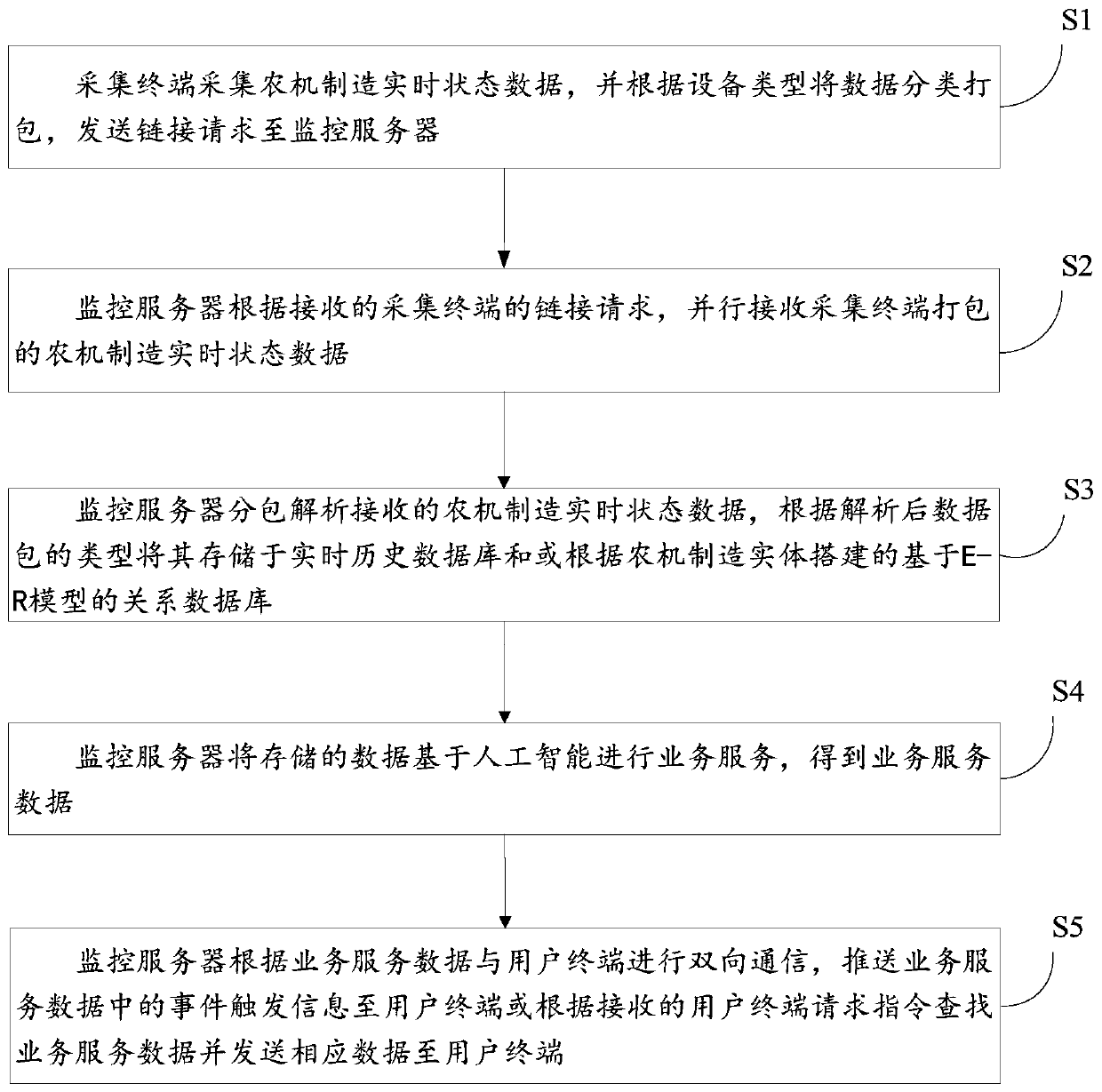

[0084] Such as figure 1 As shown, an IoT monitoring method for agricultural machinery manufact...

Embodiment 2

[0110] According to an aspect of one or more embodiments of the present disclosure, an IoT monitoring system for agricultural machinery manufacturing is provided.

[0111] Such as Figure 7 As shown, an agricultural machinery manufacturing Internet of Things monitoring system, which is based on the described agricultural machinery manufacturing Internet of Things monitoring method, includes: a perception layer, a data layer, a service layer, and an application layer connected in sequence;

[0112] The perception layer is used to collect real-time status data of agricultural machinery manufacturing by using a collection terminal, classify and package the data according to the equipment type, and send a link request to the data layer;

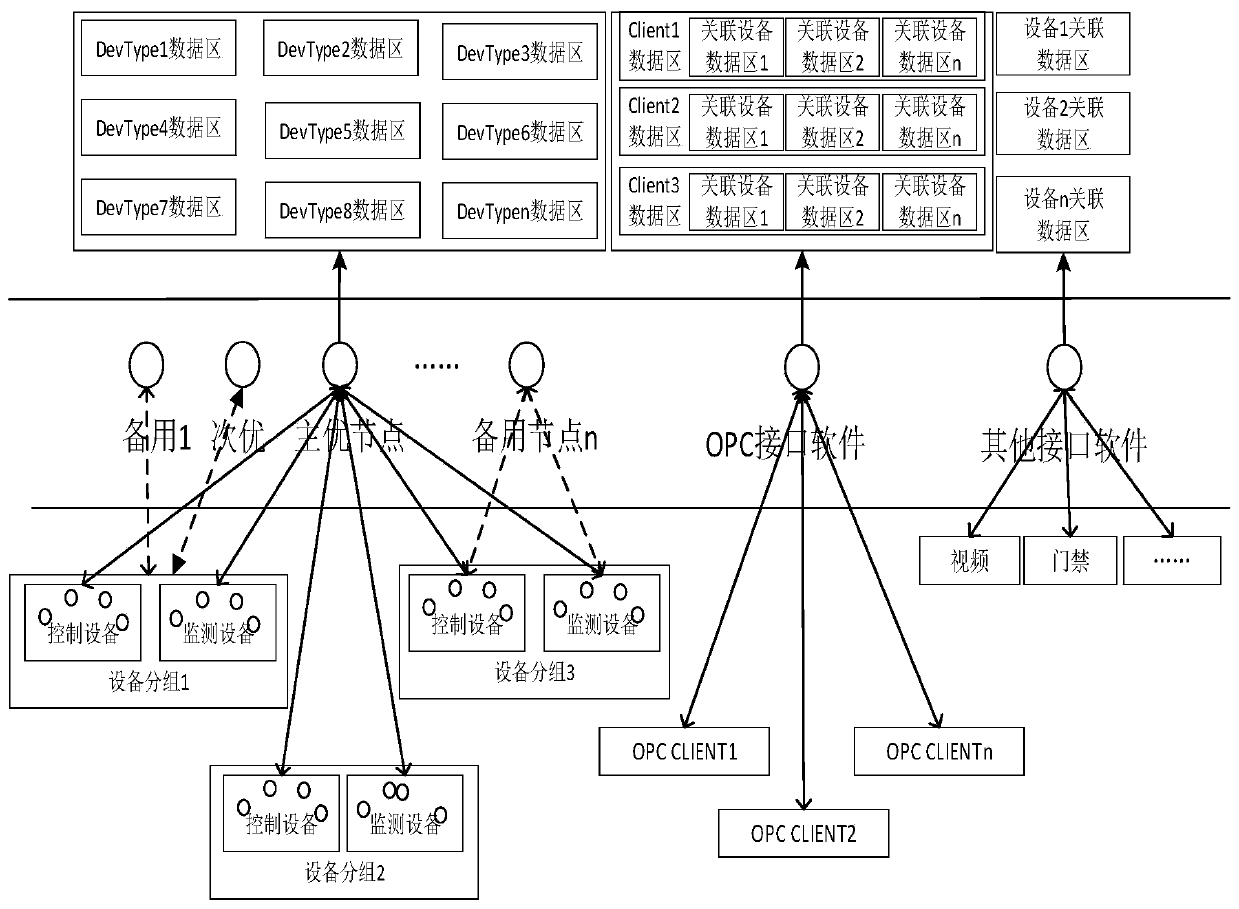

[0113] The data layer is used to use the monitoring server to receive the real-time status data of agricultural machinery manufacturing packaged by the collection terminal in parallel according to the received link request of the collection terminal; sub...

Embodiment 3

[0140] According to an aspect of one or more embodiments of the present disclosure, there is provided an IoT monitoring method for agricultural machinery manufacturing.

[0141] A monitoring method for the Internet of Things in agricultural machinery manufacturing, which is implemented in a monitoring server, and includes:

[0142] Receive the link request of the collection terminal, and receive the real-time status data of agricultural machinery manufacturing packaged by the collection terminal according to the equipment type according to the link request of the collection terminal;

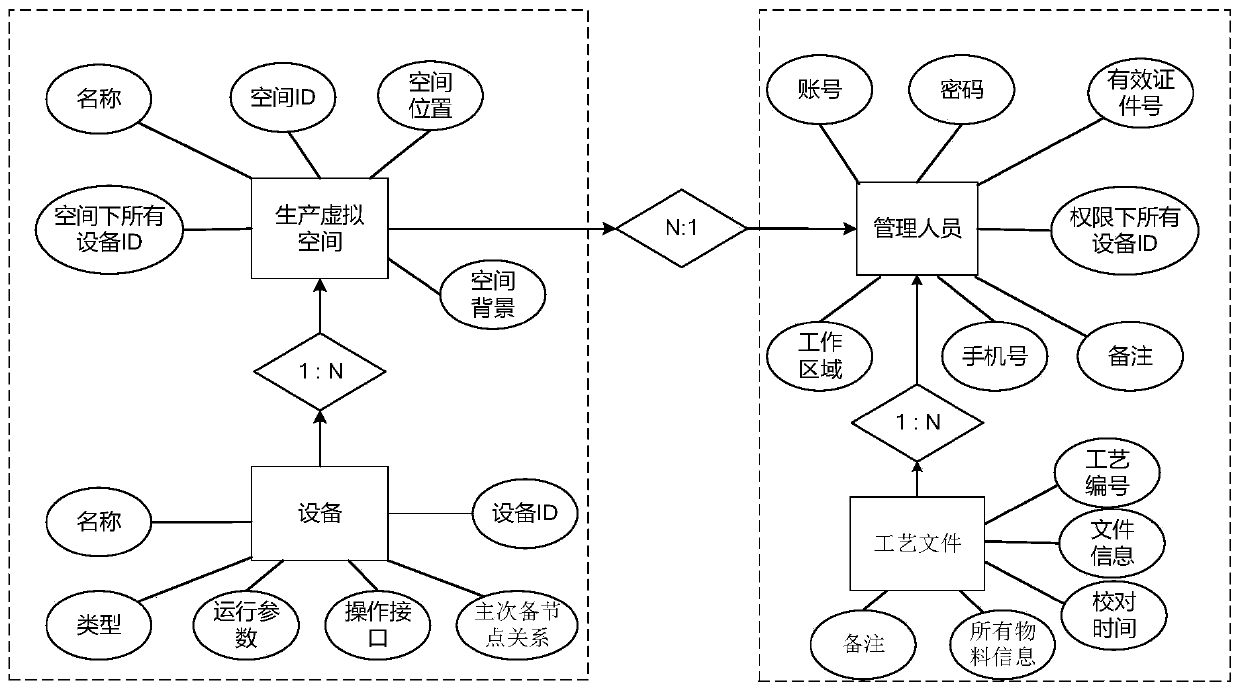

[0143] Subcontract analysis of the received real-time status data of agricultural machinery manufacturing, and store it in real-time database, historical database or relational database based on E-R model built according to the entity of agricultural machinery manufacturing according to the type of the analyzed data packet;

[0144] Perform business services on the stored data based on artificial intelli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com