Method for connecting intermittent discrete steel structure pipe joints jacked in batches and tunnel portal

A connection method and technology for steel structures, which are applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of long time, difficult to guarantee the construction quality of the tunnel ring beam, and limited leakage plugging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

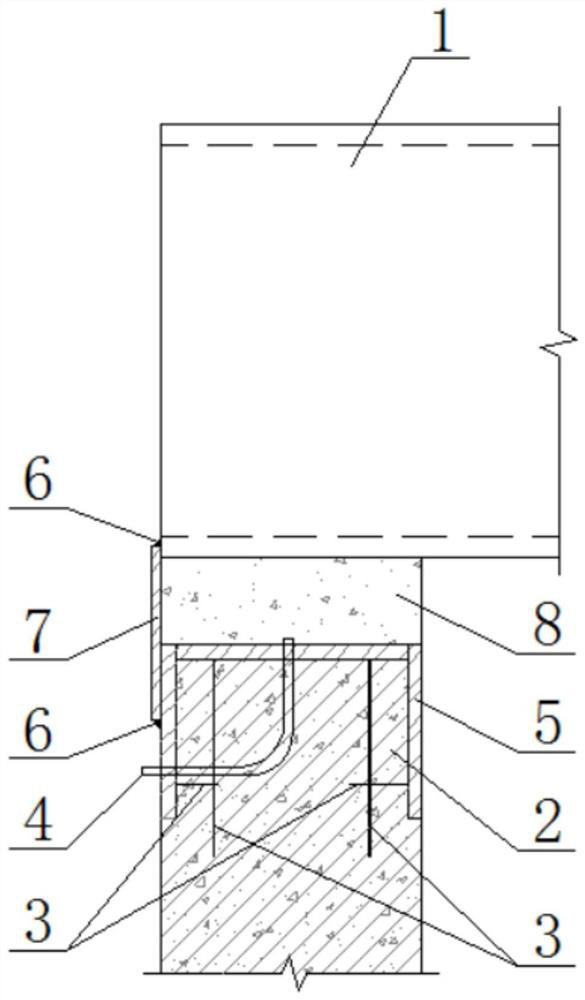

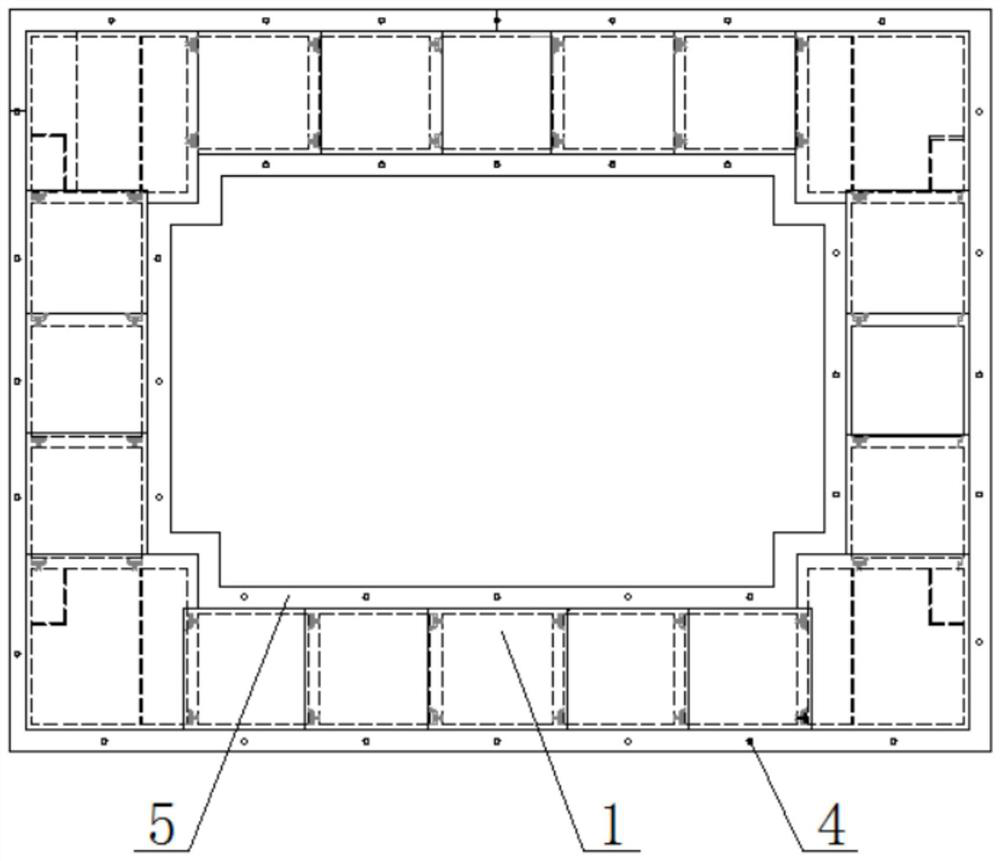

[0029] Such as Figure 1-Figure 2 As shown, a specific embodiment of a method for connecting discrete steel structure pipe joints and portals with gaps for jacking in batches according to the present invention includes the following steps:

[0030] Step 1. Before the steel pipe section 1 is jacked, pre-compose the steel pipe section 1 to prepare for construction;

[0031] Step 2, pre-embed the anchor bar 3 and the door ring 5 on the inner lining side wall 2, the anchor bar 3 and the door ring 5 are welded and connected, and the door ring 5 is made of a steel plate;

[0032] Step 3, pre-embed the grouting pipe 4 in the inner lining side wall 2, the grouting pipe 4 is a seamless steel pipe with internal threads at both ends;

[0033] Step 4: Jacking of the steel pipe section 1, after the completion of the jacking of the steel pipe section 1, the gap between the lining side wall 2 and the steel pipe section 1 is sealed with concrete 8 through the grouting pipe 4;

[0034] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com