Integral rotary precession type rock roadway cutting machine

A cutting machine, rock technology, applied in tunnels, shaft equipment, mining equipment, etc., can solve problems such as inability to construct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

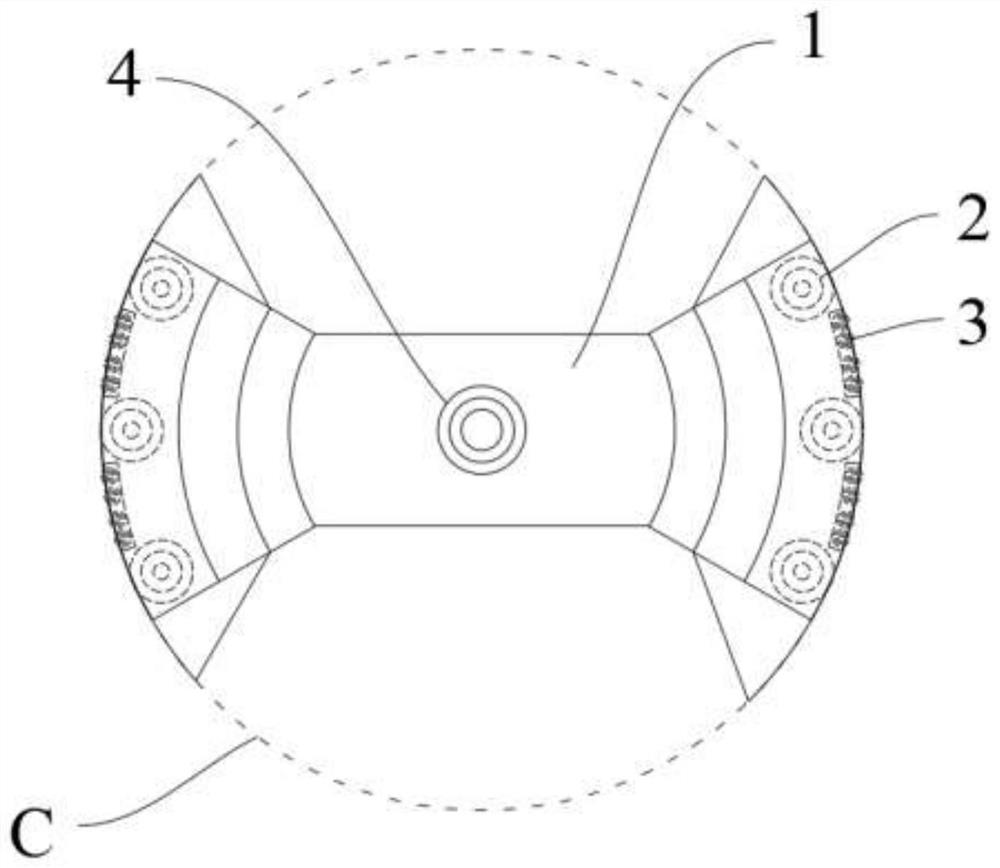

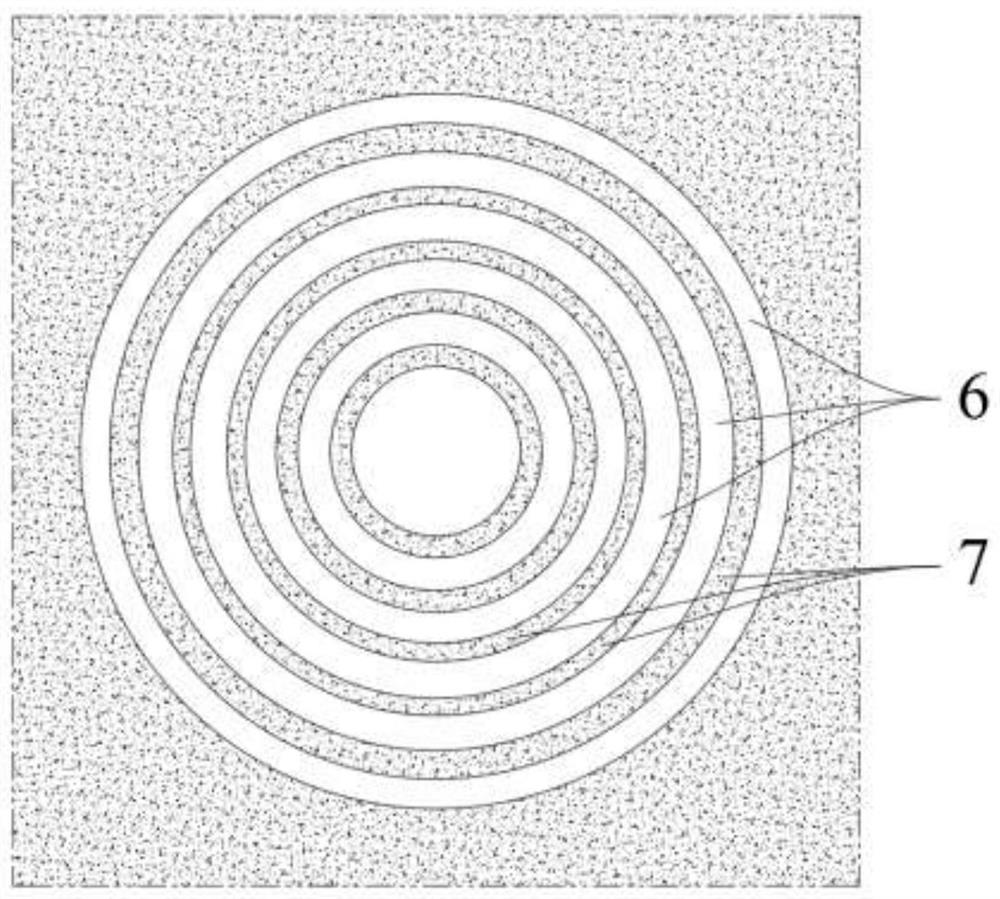

[0038] Such as Figures 1 to 6 As shown, this embodiment provides an integral rotary rotary rock roadway cutting machine, including a rotary cutting platform 1; the outer peripheral side of the rotary cutting platform 1 is provided with a first drive mechanism 2, the first drive mechanism 2 is used to Drive the rotary cutting platform 1 to rotate and drill or retract in the axial direction; the front side of the rotary cutting platform 1 is provided with multiple sets of cutter sets 5; the cutter sets 5 include at least a first cutter 51 and a second cutter 52; The first cutter 51 is used to form the annular drill groove 6, and the second cutter 52 is used to expand the rear end of the annular drill groove in the radial direction; between the annular drill grooves formed by adjacent tool groups 5 Form the thin-walled rock ring 7; the cutter set 5 also includes a third cutter 53 for cutting the thin-walled rock ring 7; wherein, each annular drilling groove 6 corresponds to at l...

Embodiment 2

[0044] The difference between the overall rotary rotary rock roadway cutting machine of this embodiment and the first embodiment is that the distribution range of the conductive slip ring 4 is located in the middle area from the axis center to the outer periphery of the rotary cutting platform 1, specifically as Figure 7 As shown, the drilling groove cut by a kind of integral rotary rotary rock roadway cutting machine of the present embodiment is as follows Figure 8 shown; it should be noted that, Figure 7 The reference sign C in represents the maximum cutting line of the cutter located at the front side of the rotary cutting platform 1 .

Embodiment 3

[0046] An integral rotary rotary rock roadway cutting machine in this embodiment differs from the first embodiment in that: the distribution range of the conductive slip ring 4 is located near the outer peripheral area of the rotary cutting platform 1, specifically as follows Figure 9 shown.

[0047] Embodiment 2 and Embodiment 3 provide different designs of conductive slip ring 4 and rotary cutting platform 1 from Embodiment 1.

[0048] It should be noted, Figure 9 The reference sign C in represents the maximum cutting line of the cutter located at the front side of the rotary cutting platform 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com