Basic mode jaw self locking speed differential gear

A differential and jaw-type technology, which is applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of unreasonable attachment of a single blocking ring, and the use performance and manufacturing process have not been improved. Or solve problems, to achieve the simple effect of eliminating collision wear phenomenon, separation blocking and fitting reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Necessary Note: In the text of this manual and all drawings, the same or similar components and their characteristic parts use the same symbols, and they are only given detailed descriptions when they appear for the first time, and will not be repeated when they appear again. Give repeated elaborations.

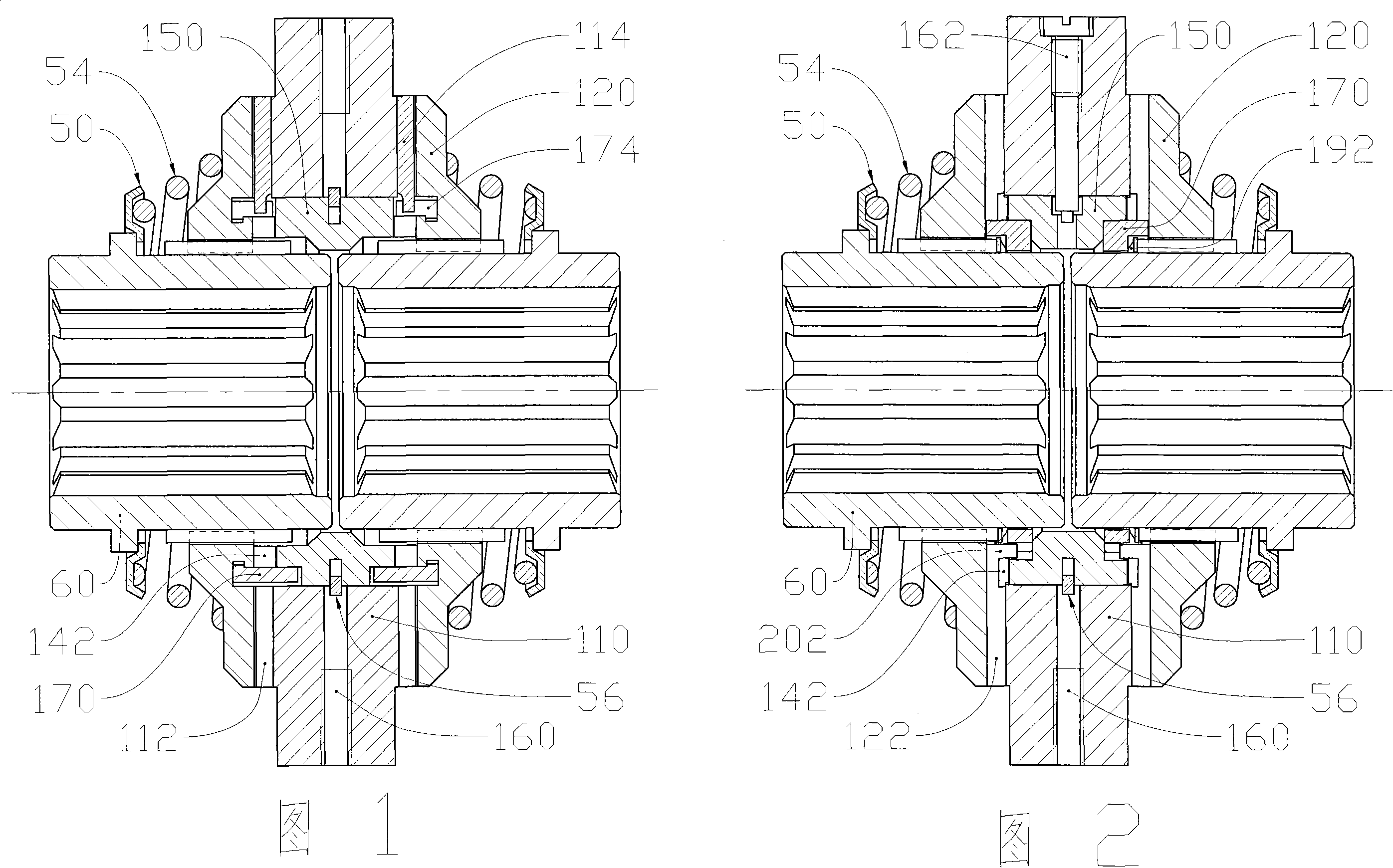

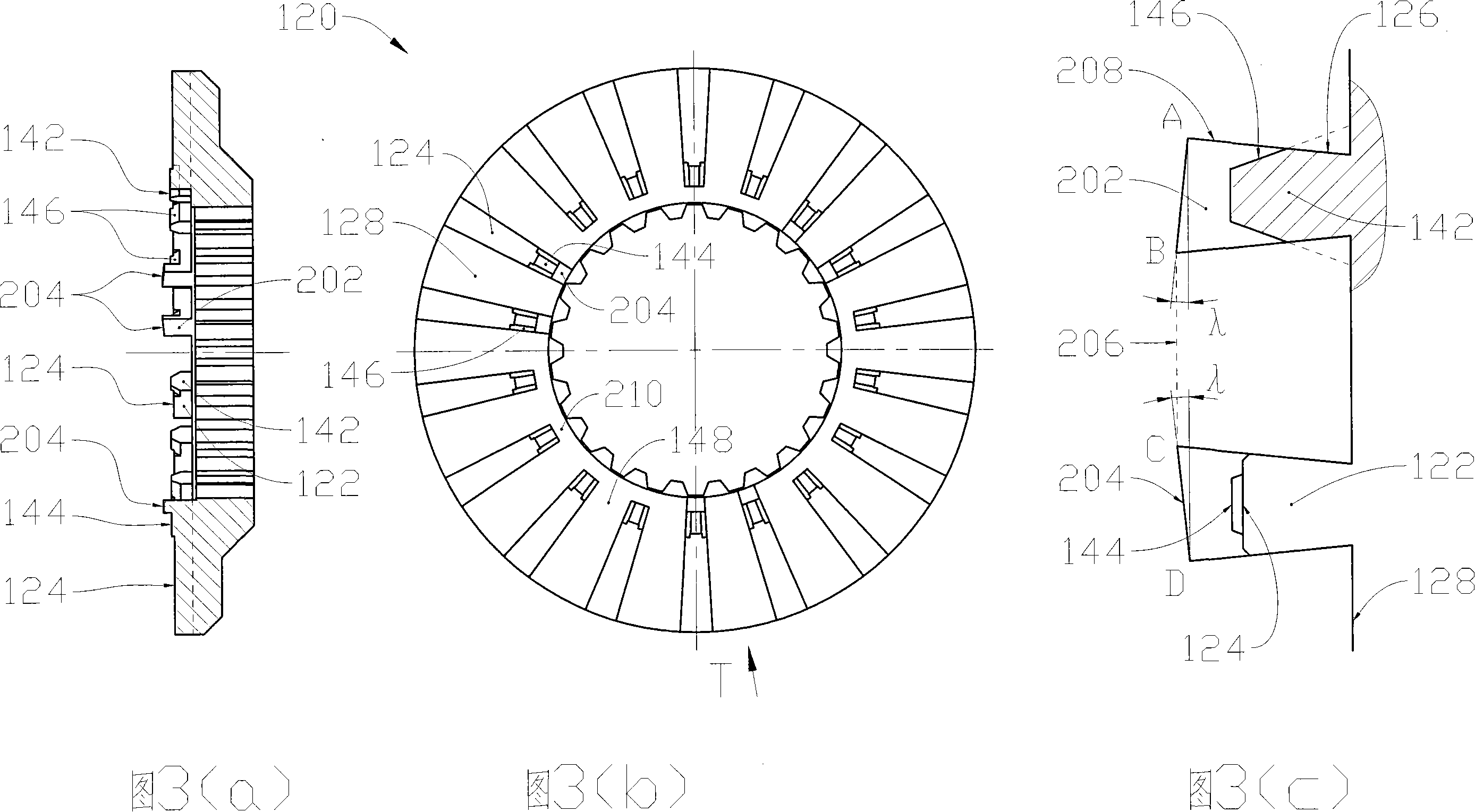

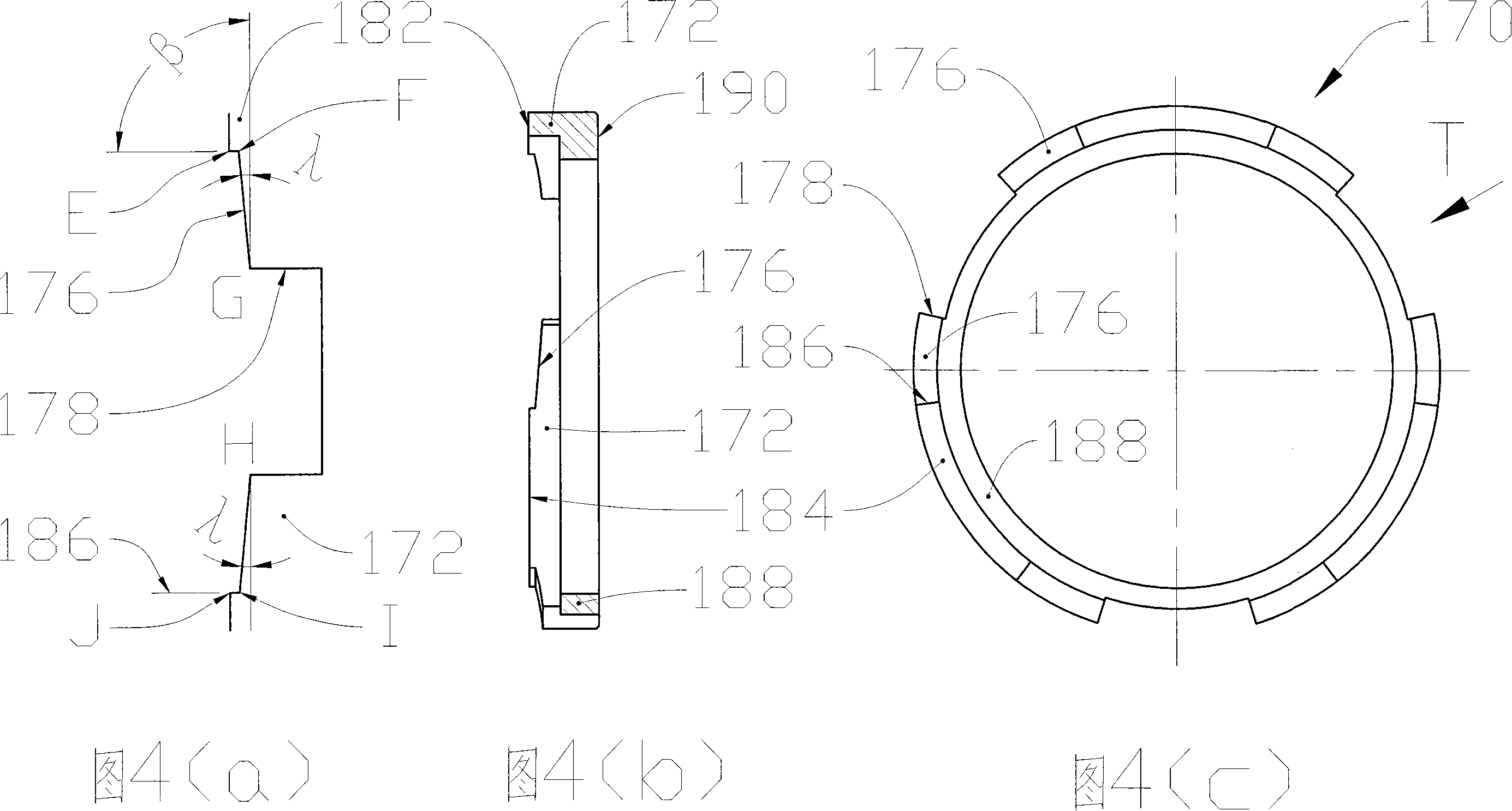

[0063] 2 to 5 show the first embodiment of the present invention, that is, the preferred embodiment of the present invention. The central ring 150 is embedded in the inner hole of the driving ring 110 and is axially fixed by the snap ring 56. The two driven rings 120 are installed at both ends of the driving ring 110. The mating end faces of the four rings face each other to form two force transmission inserts. One mechanism and two separate fitting mechanisms. The two springs 54 respectively press the driven ring 120 from both ends to ensure continuous presence of the fitting pressure, and the outer ends of the two springs 54 are supported by the two spring seats 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com