Self-adhesive polymer modified asphalt waterproof coiled material and preparation method thereof

A technology of modified asphalt and waterproof membrane, which is applied in the direction of asphalt material adhesive, adhesive type, oil/fat/wax adhesive, etc. It can solve the problems of insufficient waterproof performance and insufficient peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

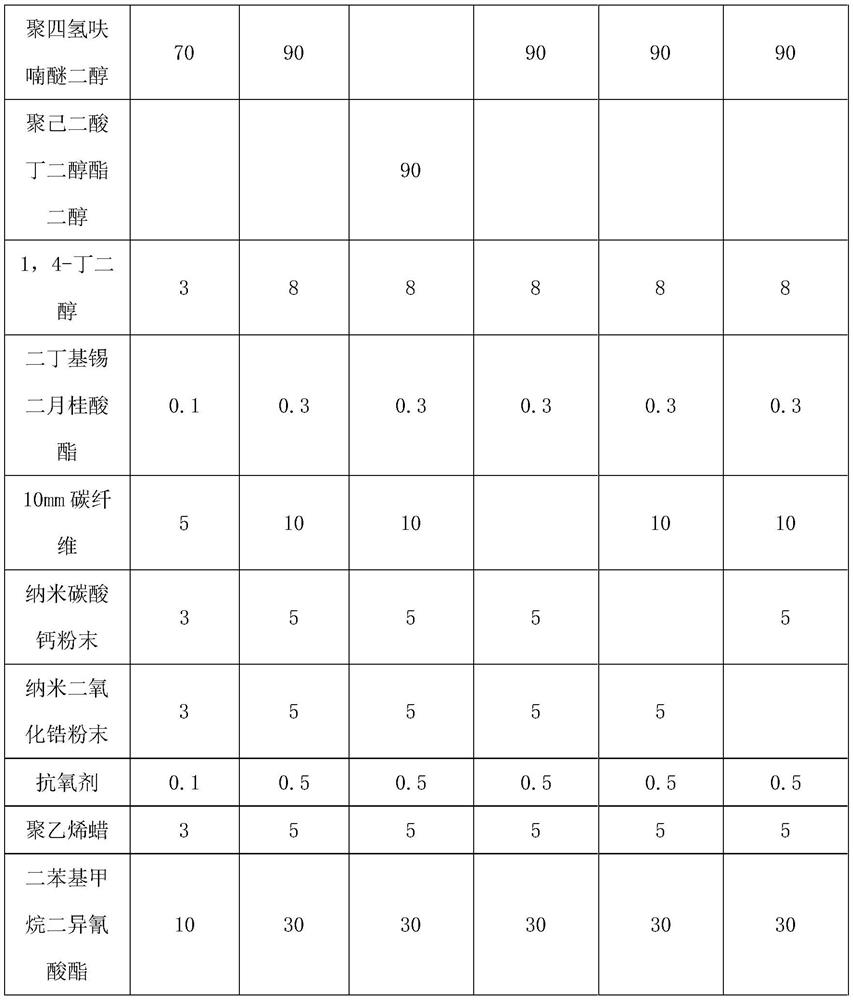

[0058]Example 1, Example 2, and Comparative Examples 1 to 6 The preparation method of the waterproof coiled material samples is as follows: the upper and lower surfaces of the base layer are uniformly coated with modified asphalt to obtain a three-layer structure, and then in the three-layer structure The upper and lower surfaces are covered with isolation layers to obtain a waterproof membrane;

[0059] Wherein, the preparation method of the modified asphalt is as follows: adding the mixed asphalt into the reactor, controlling the temperature of the reactor at 170° C., starting the stirring, and slowly adding the stabilizer, thermoplastic polyurethane resin, SBS resin, tackifying resin, (3, 3-dimethylbutyl) triethoxysilane, after being stirred uniformly, the material is discharged to obtain the modified asphalt.

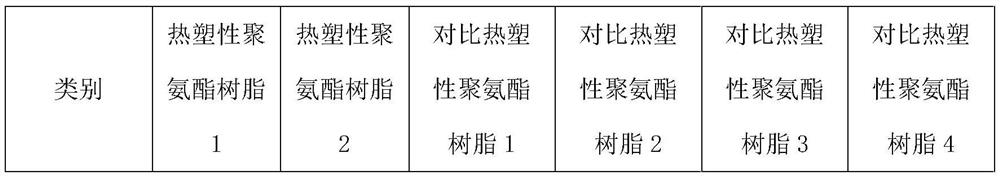

[0060] The types and amounts of raw materials used to prepare modified asphalt in Example 1, Example 2, and Comparative Examples 1-6 are listed in Table 2, in terms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com