A liquid fully degradable mulch film and its preparation method

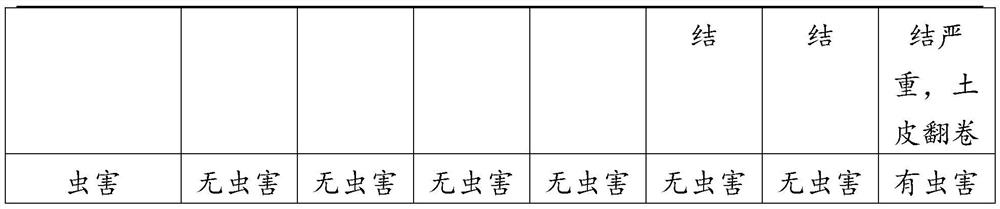

A fully degradable, mulching technology, used in biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve problems such as soil compaction, soil erosion, crop yield decline, etc. The effect of hardening and preventing pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of the liquid fully degradable mulch film, comprising the following steps:

[0038] (1) Fermenting, drying and refining after mixing corn stalks and fermentation bacteria to obtain organic materials;

[0039] (2) mixing carboxymethyl cellulose, silica sol, surfactant and water to obtain a mixed solution;

[0040] (3) Mix organic material, mixed solution, lignin sulfonate and plant extract to obtain the liquid fully degradable mulch film.

[0041] In the present invention, the fermentation temperature in the step (1) is preferably 70-80°C, more preferably 72-78°C, more preferably 74-76°C; the fermentation time is preferably 15-25 days, More preferably, it is 16 to 24 days, and more preferably, it is 18 to 22 days.

[0042] In the present invention, the drying temperature is preferably 50-60°C, more preferably 52-58°C, more preferably 54-56°C; the finer particle size is preferably 300-400nm, more preferably 320nm ...

Embodiment 1

[0049] Configure liquid fully degradable mulch film raw materials according to the following standards:

[0050]70 parts of corn stalks, 4 parts of yeast, 20 parts of carboxymethyl cellulose, 10 parts of silica sol, 35 parts of calcium lignosulfonate, 20 parts of Tween 60, 12 parts of plant extracts, and 250 parts of water.

[0051] The mass concentration of the silica sol is 35 wt %, and the mass ratio of eugenol, picralin and azadirachtin in the plant extract is 1:0.5:0.25.

[0052] Prepare the liquid fully degradable mulch film according to the following method:

[0053] Mix corn stalks and yeasts and ferment at 75°C for 20 days. After the fermentation, dry at 60°C until the water content is 8%, and then refine them. The particle size after refinement is 320nm to obtain organic materials;

[0054] Carboxymethyl cellulose, silica sol, Tween 60 and water were stirred at 800 rpm for 60 min to obtain a mixed solution;

[0055] Stir the organic material, mixed solution, calciu...

Embodiment 2

[0058] Configure liquid fully degradable mulch film raw materials according to the following standards:

[0059] 60 parts of corn stalks, 3 parts of lactic acid bacteria, 25 parts of carboxymethyl cellulose, 8 parts of silica sol, 32 parts of sodium lignosulfonate, 15 parts of Span 20, 5 parts of plant extracts, 200 parts of water.

[0060] The mass concentration of the silica sol is 30 wt %, and the mass ratio of eugenol, picralin and azadirachtin in the plant extract is 1:0.45:0.28.

[0061] Prepare the liquid fully degradable mulch film according to the following method:

[0062] Mix corn stalks and lactic acid bacteria and ferment at 80°C for 15 days. After the fermentation, dry at 50°C until the water content is 7%, and then refine them. The particle size after refinement is 350nm to obtain organic materials;

[0063] Stir carboxymethyl cellulose, silica sol, Span 20 and water at 900 rpm for 50 min to obtain a mixed solution;

[0064] Stir the organic material, mixed so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com