Production process of cationic curing agent

A cationic curing agent and production process technology, applied in the direction of inorganic chemistry, antimony compounds, chemical instruments and methods, etc., can solve the problems of complex impurity removal process, high cost of raw materials, low purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

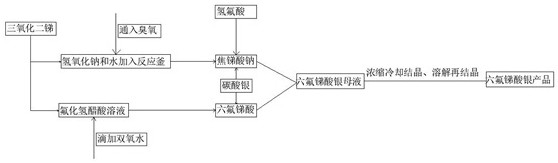

[0028] Such as figure 1 Shown a kind of cationic curing agent production process, concrete production process is as follows:

[0029] S1: Preparation of sodium pyroantimonate: Add sodium hydroxide and water to the reaction kettle, then add antimony trioxide, and react at a constant temperature of 80-120°C for 2 hours; cool down to 30-50°C, and inject ozone while stirring to carry out Oxidation reaction for 5 hours; then heat up to 100°C, stand for crystallization, centrifuge, and dry to obtain sodium pyroantimonate;

[0030] S2: Preparation of hexafluoroantimonic acid: at 60-120°C, mix antimony trioxide with acetic acid solution containing hydrogen fluoride, then add hydrogen peroxide dropwise at a rate of 5mL / min while stirring, and obtain hexafluoroantimony after the reaction is complete acid solution;

[0031] S3: Preparation of silver hexafluoroantimonate mother liquor: under the condition of 60-120°C, equimolar amounts of sodium pyroantimonate solid and silver carbonate...

Embodiment 2

[0038] Such as figure 1 Shown a kind of cationic curing agent production process, concrete production process is as follows:

[0039] S1: Preparation of sodium pyroantimonate: Add sodium hydroxide and water to the reaction kettle, then add antimony trioxide, and react at a constant temperature of 80-120°C for 3 hours; cool down to 50°C, and introduce ozone while stirring to carry out oxidation reaction 6 hours; then heat up to 100°C, stand for crystallization, centrifuge, and dry to obtain sodium pyroantimonate;

[0040] S2: Preparation of hexafluoroantimonic acid: at 60-120°C, mix antimony trioxide with acetic acid solution containing hydrogen fluoride, then add hydrogen peroxide dropwise at a rate of 15mL / min while stirring, and obtain hexafluoroantimony after the reaction is complete acid solution;

[0041] S3: Preparation of silver hexafluoroantimonate mother liquor: under the condition of 60-120°C, equimolar amounts of sodium pyroantimonate solid and silver carbonate so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com