An embedded two-way welding process for steel pipes

A welding process, built-in technology, applied in the direction of welding equipment, welding medium, welding equipment, etc., can solve the problems of reduced welding strength and easy fracture of two steel pipes, achieve high welding strength, dense and stable welding layer, and improve welding quality. intensity effect

Active Publication Date: 2022-06-03

河北方泉管道装备有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

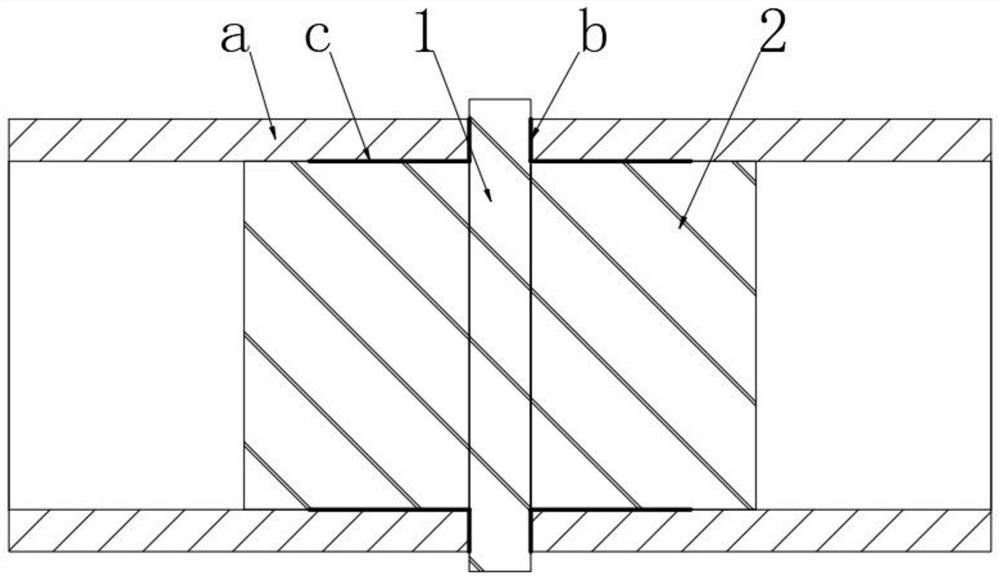

[0004] Regarding the welding of two steel pipes, in the prior art, the two steel pipes are usually welded at the cross section close to each other, and the connection is only realized through this place, but in this way, one welding in the radial direction leads to a decrease in the overall welding strength, When cracks occur in the weld, the two steel pipes are easily broken

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

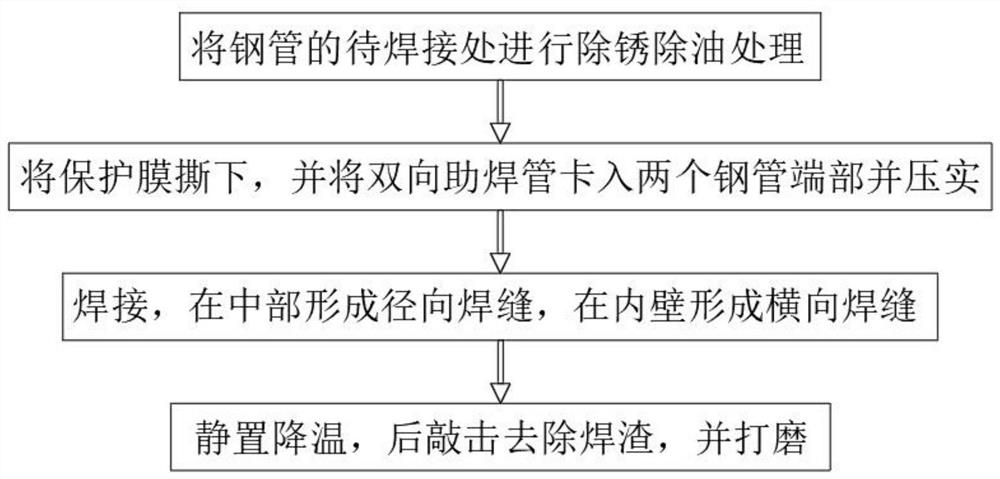

[0055] S4, stand and cool down, the rear knock removes the welding slag, and grinds to complete the welding.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

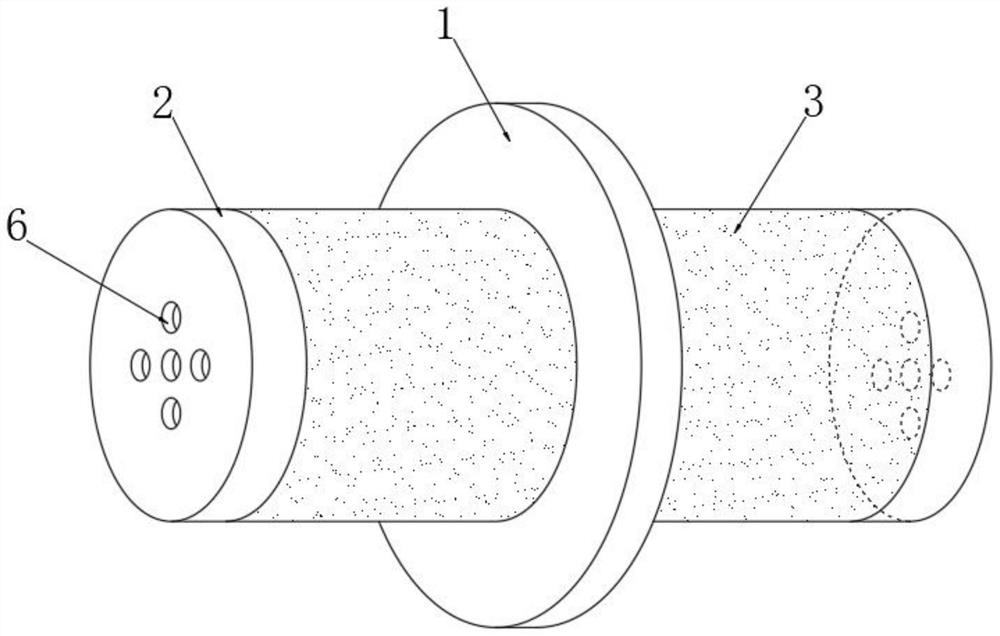

The invention discloses a steel pipe embedded two-way welding process, which belongs to the field of welding. A steel pipe embedded two-way welding process, through the arrangement of two-way welding aid pipes, during high-temperature welding, the outer welding sheet can be formed on the cross-section of two steel pipes Radial welding seam, after heating, the inner welding powder block melts and contacts with the inner wall of the steel pipe, and can form a transverse weld seam inside. Compared with the radial weld seam in the prior art, the welding strength is significantly improved, and the welded steel pipe is not easy to weld. Cracking and breaking, and at the same time, in conjunction with the temporarily sealed environment in the horizontal welded pipe, the high thermal conductivity gas expands after being heated. On the one hand, the molten inner welding powder is pushed by the metal shrapnel, so that the welding layer formed by the molten inner welding powder and the inner wall of the steel pipe is more dense. It is stable and further improves the welding strength. On the other hand, the high thermal conductivity gas pushes the hollow pre-sealed ball to separate it from the horizontal welded pipe and contact the sealing performance of the horizontal welded pipe, effectively preventing the high thermal conductivity gas from expanding and causing the transverse welded pipe to burst due to excessive expansion.

Description

A kind of steel pipe embedded two-way welding process technical field [0001] The present invention relates to the field of welding, and more particularly, to a steel pipe embedded bidirectional welding process. Background technique Welding, also known as welding, is the joining of metals or other thermoplastic materials by means of heat, high temperature, or high pressure. The manufacturing process and technology of materials such as plastics. [0003] There are many sources of energy for modern welding, including gas flame, arc, laser, electron beam, friction and ultrasonic Wait. In addition to being used in factories, welding can be performed in a variety of environments, such as in the field, underwater, and in space. wherever Wherever welding is possible, it may bring danger to the operator, so appropriate protective measures must be taken when welding. welding to people Possible injuries to the body include burns, electric shock, visual impairment, inhalation...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K31/02B23K35/00B23K35/02B23K37/00

CPCB23K31/02B23K35/00B23K35/0255B23K37/00

Inventor 丘永梅

Owner 河北方泉管道装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com