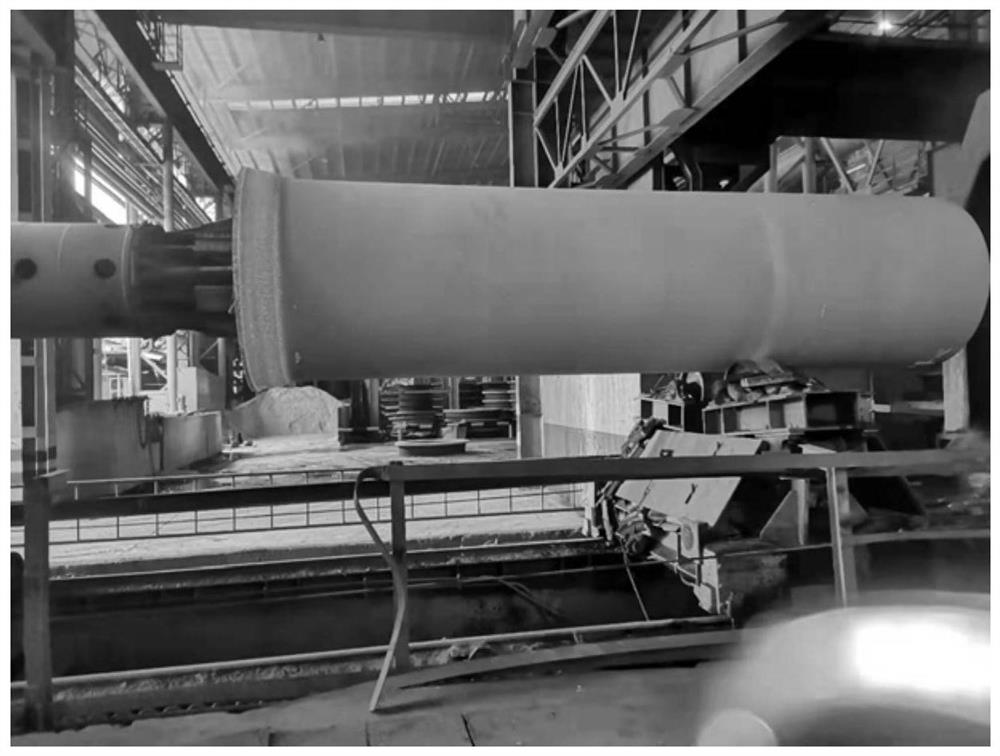

Large-diameter nodular cast iron pipe die coating and preparation method and application thereof

A nodular cast iron pipe and large-diameter technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of small bulk density, low refractive index, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0045] 1. Preparation of large diameter ductile iron pipe mold coating

[0046] The present invention provides a kind of preparation method of large diameter ductile iron pipe mold coating, comprises the following steps:

[0047] (1) Preparation of composite suspending agent

[0048] 1. In parts by weight, weigh 100 parts of rectorite and add it to 1000 parts of water, stir evenly, add 6 parts of amino-containing silane compound (KH550) after heating up to 80°C, react for 12 hours, and filter to obtain amino-modified retort stone;

[0049] 2. Add the amino-modified rectorite and succinic anhydride obtained in step 1 into the solvent according to the molar ratio of carboxyl and amino groups of 1:1, adjust the pH value to 4.0 and react for 6 hours, then filter and dry to prepare carboxylated rectorite ;

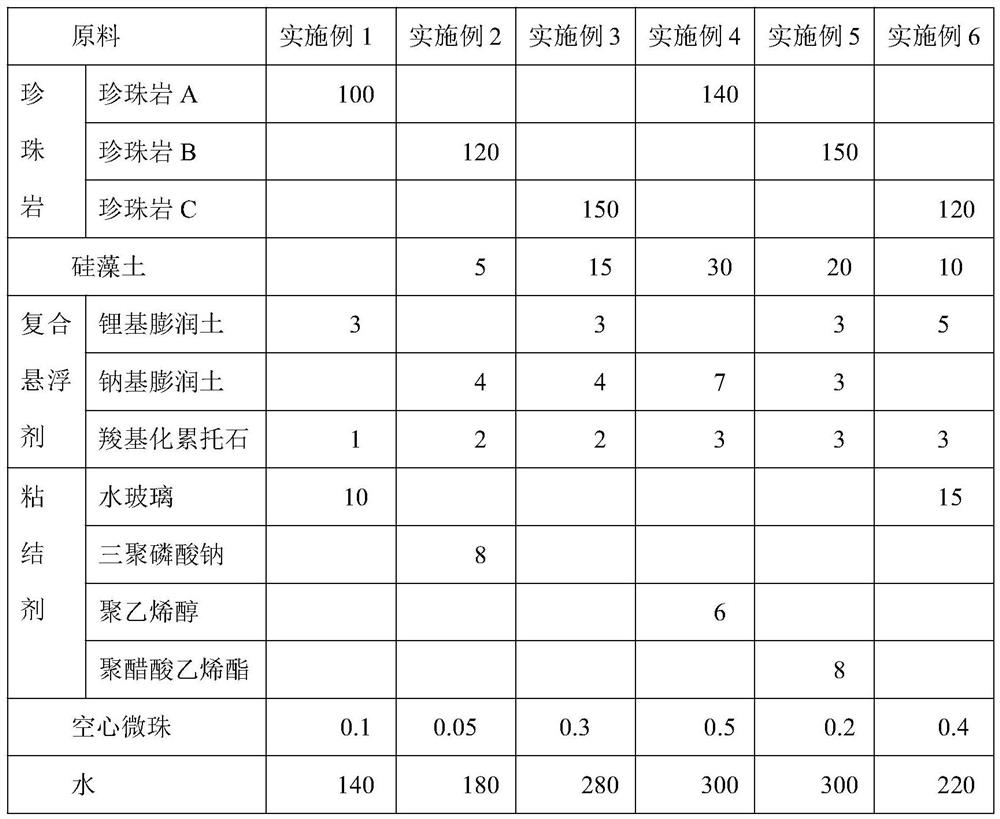

[0050] 3. The carboxylated rectorite obtained in step 2 is mixed with sodium bentonite and / or lithium bentonite according to the formulation amount in Table 1 to prepare a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com