Dodecahedral monatomic iron Fenton catalyst, and preparation and application thereof

A dodecahedron, iron catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as harmless and difficult to achieve antibiotic degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

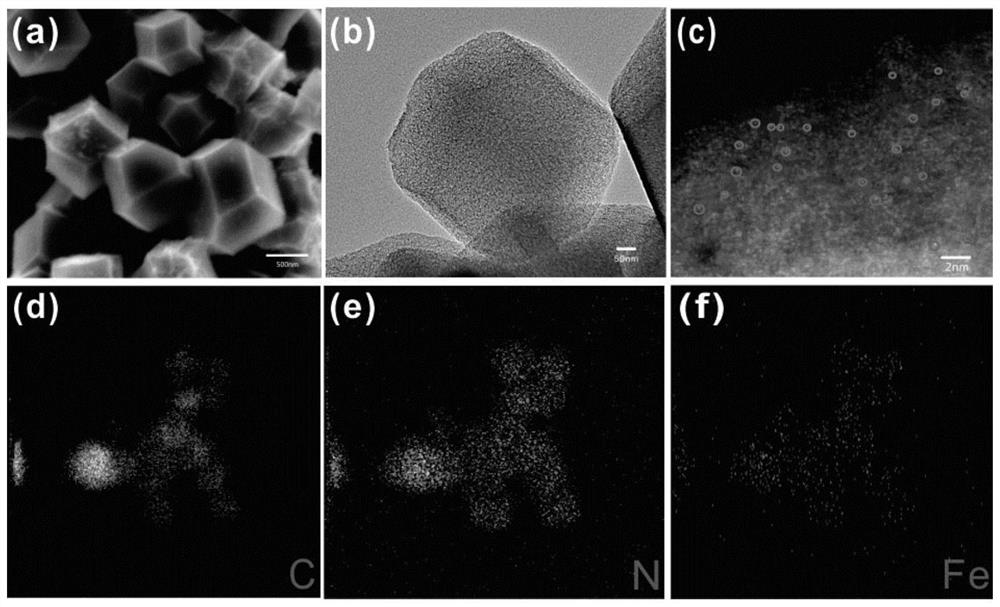

[0027] Step 1: Iron acetylacetonate, zinc nitrate hexahydrate, and dimethylimidazole were dissolved in 60 mL of methanol, wherein the molar concentration of dimethylimidazole was 0.4 mol / L; the molar concentration of zinc nitrate hexahydrate was 0.1 mol / L; The molar concentration of iron acetylacetonate was 0.01mol / L, sonicated for 15min, and stirred for 1h to obtain a brown-red solution.

[0028] Step 2: Transfer the above-mentioned brown-red solution to a 100 mL reactor and put it into an oven for solvothermal reaction for 4 hours at a reaction temperature of 120°C.

[0029] Step 3: The solution obtained from the above reaction was centrifuged, washed three times with methanol and N, N dimethylformamide, and dried in vacuum at 60°C for 12 hours to obtain the MOFs-loaded precursor material.

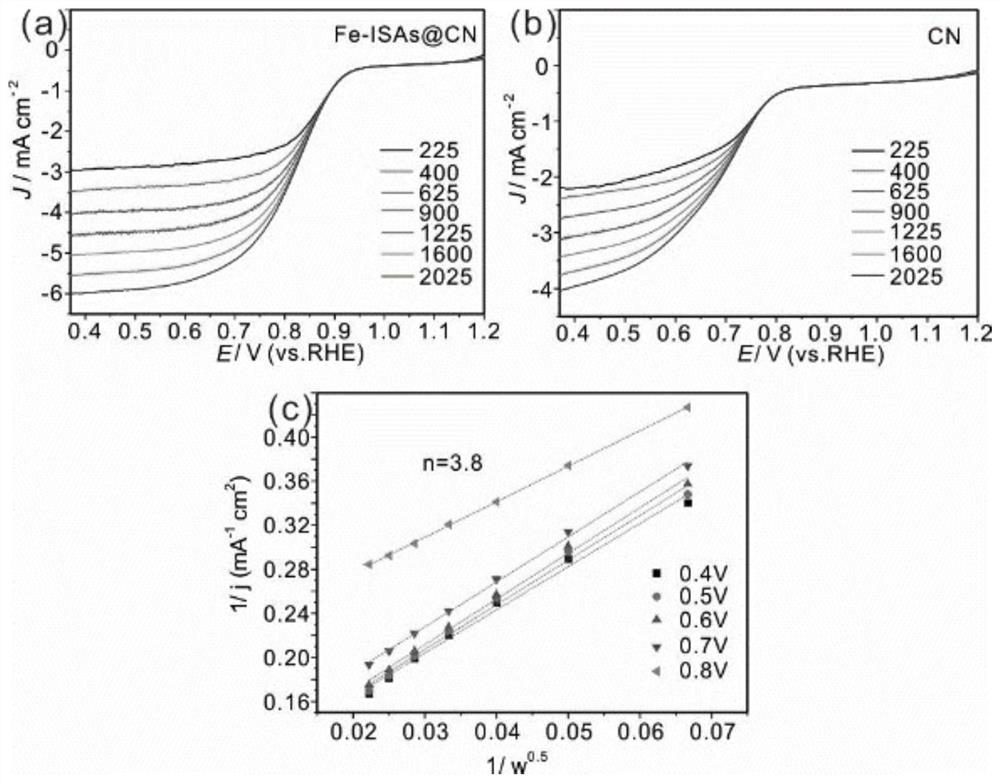

[0030] Step 4: Grind the obtained precursor into powder and put it into a tube furnace. Under the protection of argon atmosphere, after calcination at a high temperature of 930°C for 3 h...

Embodiment 2

[0035] Step 1: Iron acetylacetonate, zinc nitrate hexahydrate, and dimethylimidazole were dissolved in 60 mL of methanol, wherein the molar concentration of dimethylimidazole was 0.4 mol / L; the molar concentration of zinc nitrate hexahydrate was 0.1 mol / L; The molar concentration of iron acetylacetonate was 0.01 mol / L, sonicated for 15 minutes, and stirred for 1 hour to obtain a brown-yellow solution.

[0036] Step 2: Transfer the above-mentioned brown-red solution into a 100mL reactor and put it into an oven for solvothermal reaction for 4 hours at a reaction temperature of 120°C.

[0037] Step 3: The solution obtained from the above reaction was centrifuged, washed three times with methanol and N, N dimethylformamide, and dried in vacuum at 60°C for 12 hours to obtain the MOFs-loaded precursor material.

[0038] Step 4: Grind the obtained precursor into powder and put it into a tube furnace. Under the protection of argon atmosphere, calcinate at a high temperature of 900°C f...

PUM

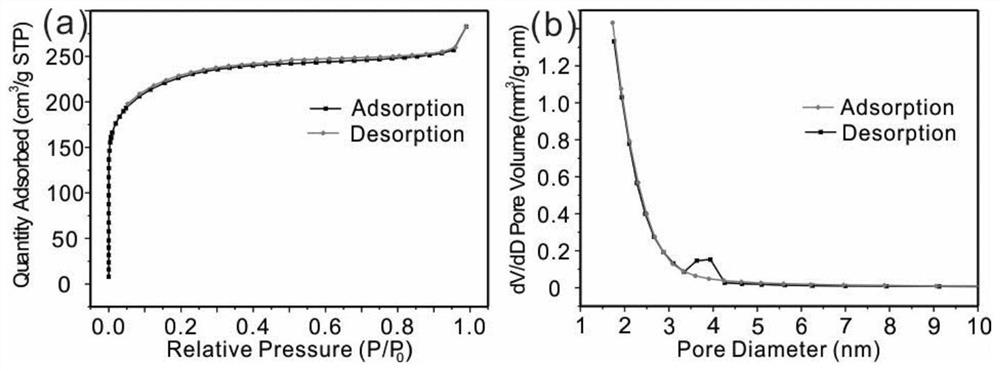

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com