Camellia blend oil capable of enhancing immunity and processing method thereof

A processing method and oil blending technology, which is applied in the fields of edible oil/fat, fat oil/fat production, fat oil/fat refining, etc., and can solve problems such as insufficient moisture, coking of raw materials, and increase of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

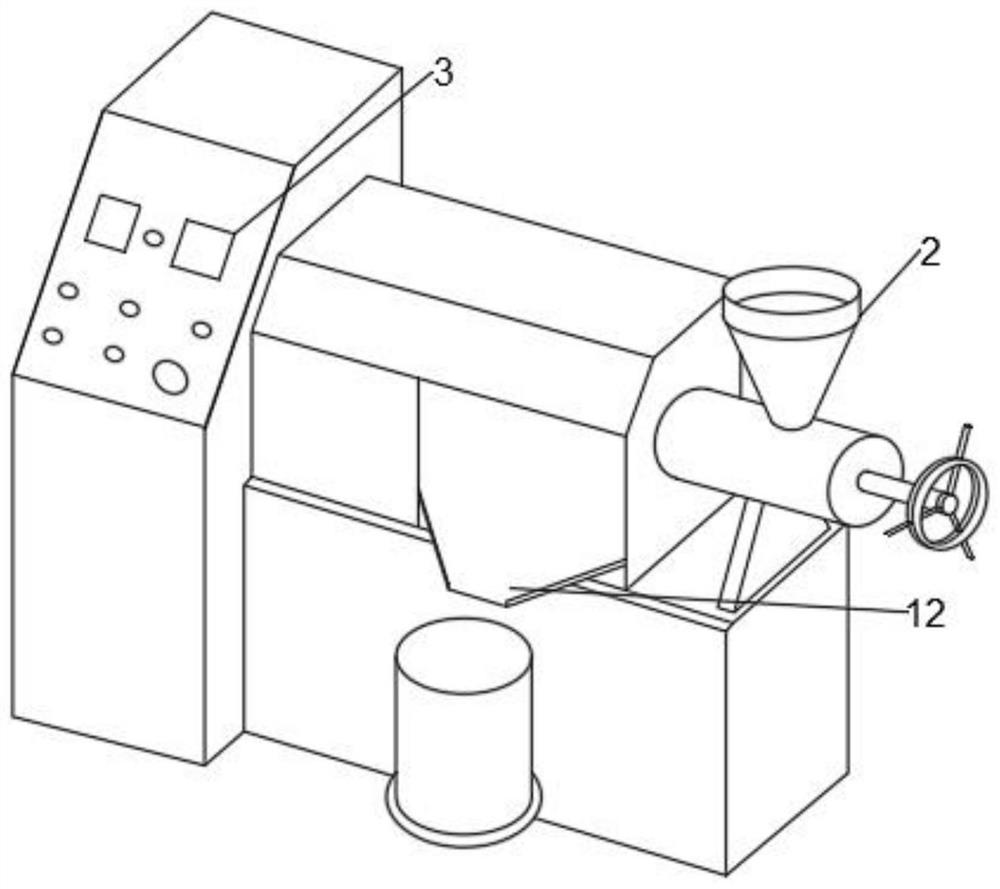

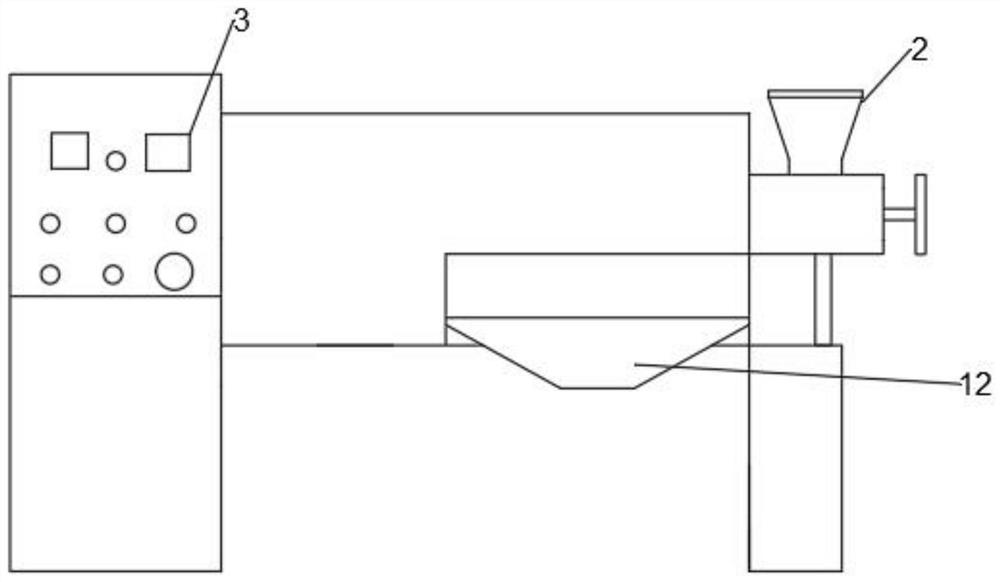

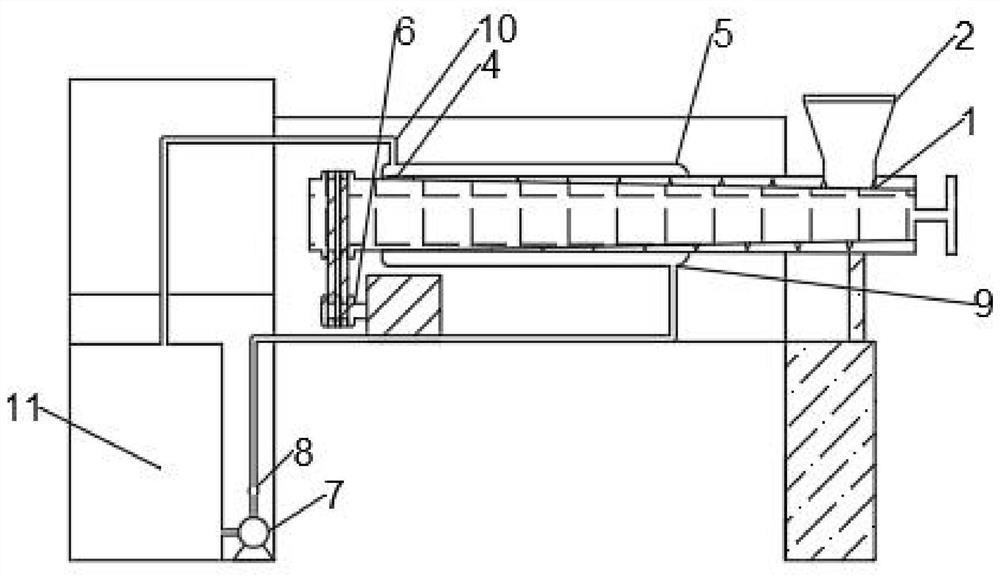

Method used

Image

Examples

Embodiment 1

[0044] An improved animal tea and oil, which is the step of:

[0045] (1) Oil tea seed pretreatment: Choose 20kg particles full of oil tea seed wash drying, then put the oil tea seeds into the pulverizer and pulverized, and the granules after pulverize it into the bucket.

[0046] (2) Non-transgenic soybean pretreatment: 13kg non-transgenic soy peel, dry, then put it in a pulverizer, and the pulverized particles are prepared in the bucket;

[0047] (3) Peanut Pretreatment: Wash the 13kg particles full of peanuts and dry, then put peanuts into the pulverizer and remove the red dress, and the pulverized particles are prepared in the bucket;

[0048] (4) Pressure of bitter vegetables: Wash the 14kg bitter seeds, put it into the crushing machine in the pulverizer, and the granules after pulverize it into the barrel;

[0049] (5) Almond pretreatment: put the 9kg almonds in hot water in 85 ~ 90 ° C, drifting 2 to 3 minutes, then removes the cold water and then peeled, then coarse pulver...

Embodiment 2

[0059] An improved animal tea and oil, which is the step of:

[0060] (1) Oil tea seed pretreatment: Wash the 15kg particles full of oil tea seeds, put it into the crusher;

[0061] (2) Non-transgenic soybean pretreatment: 10kg non-transgenic soy peel, dry, then put it in a crusher;

[0062] (3) Peanut Pretreatment: Wash 10kg particles with a full peanut, then put peanuts into the pulverizer and remove the red dress, and the granules after pulverize are prepared in the bucket;

[0063] (4) Pretreatment of bitter vegetables: Wash 10kg bitter vegetables, then put it into the crusher and crushing;

[0064] (5) Almond pretreatment: 5kg almond is put into hot water in 85 ~ 90 ° C, drifting 2 to 3 minutes, then removed, cold water quickly cools and peeled, then crude crushing;

[0065] (6) Roller: Put the pretreated oil tea seed, non-genetically modified soy, bitter vegetarian seed, almond particles in different ratios, and then feed into the mixed kettle, then feed into the roller step...

Embodiment 3

[0074] An improved animal tea and oil, which is the step of:

[0075] (1) Pretreatment of oil tea seeds: Wash 25kg particles to wash the tea seeds, then select the full granules of oil tea seeds into the pulverizer;

[0076] (2) Non-transgenic soybean pretreatment: 15kg non-transgenic soy peel, dry, then put it in a crusher;

[0077] (3) Pressure of bitter vegetables: Wash 15kg bitter vegetaria seeds, then put it into the crushing machine;

[0078] (4) Peanut Pretreatment: Wash the 15kg particles full of peanuts and dry, then put the peanuts into the pulverizer and remove the red dress, and the granules after pulverizing are prepared in the bucket;

[0079](5) Almond pretreatment: put 10kg almonds into hot water in 85 ~ 90 ° C, drifting 2 ~ 3min, take out, cold water quickly cool, then rough crushing;

[0080] (6) Roller: Put the pretreated oil tea seed, non-genetically modified soy, bitter vegetarian seed, almond particles in different ratios, and then feed into the mixed kettle,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com