Castanea mollissima BL., and manufacture method and equipment thereof

A technology of chestnut and equipment, applied in chemical instruments and methods, preservation of seeds by drying, food preservation, etc., can solve problems such as less quality control research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

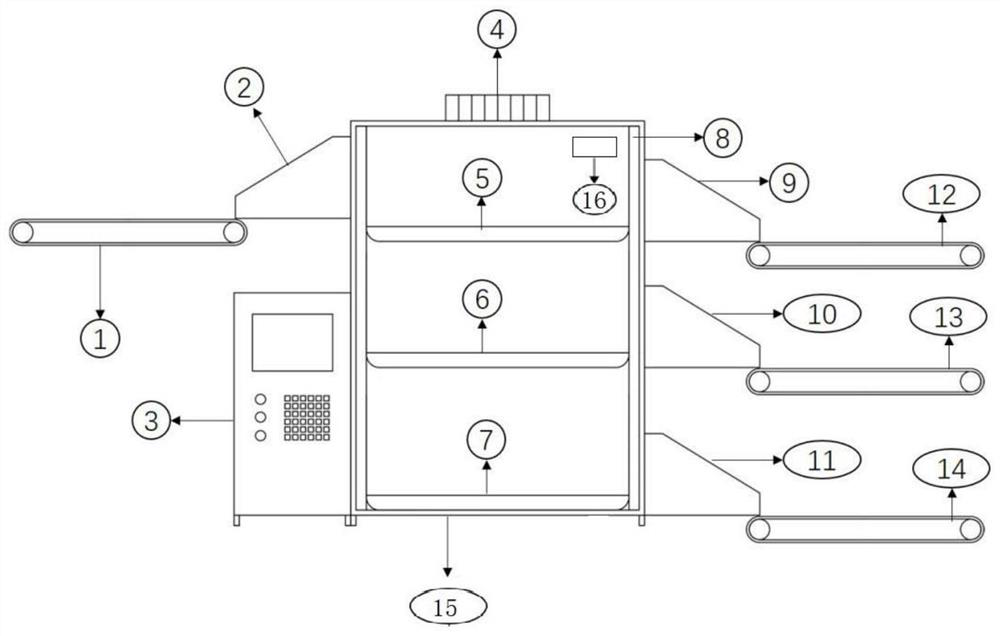

Method used

Image

Examples

Embodiment 1

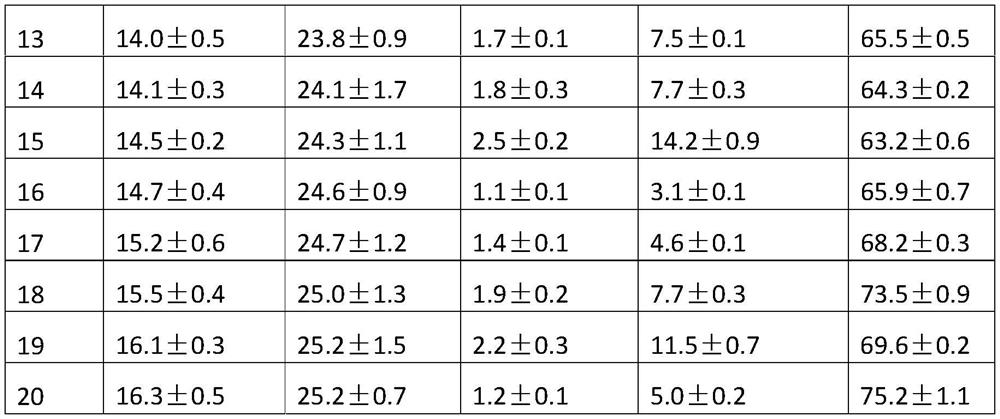

[0032] Select 20 fresh chestnuts from different origins and varieties, set the temperature at 40°C, spread the chestnut samples on a shallow plate, and air-dry for 24 hours. Measure the water-soluble sugar content, total phenol content, and glycemic index of chestnut kernels before air-drying, measure the color ΔEo value of the chestnut surface with a color difference meter; and measure the water-soluble sugar content in chestnut kernels after air-drying, the surface color ΔE of chestnut kernels, and calculate the color difference before and after air-drying (ΔE - ΔEo). The results are shown in Table 1.

[0033] It can be seen from Table 1 that the water-soluble sugar content, total phenol content, and glycemic index of different chestnuts are quite different. There is a positive correlation between the water-soluble sugar content before and after air-drying, and the higher the water-soluble sugar content, the better the sweetness of the taste. During the air-drying process ...

Embodiment 2

[0038] The preparation of the air-dried chestnut needs to be carried out at a temperature lower than the gelatinization temperature of the chestnut starch, so that the starch of the air-dried chestnut obtained in this way does not gelatinize, so the digestibility is low. Chestnut variety 11 was selected, and the chestnut samples were spread flat on shallow pans, and air-dried for different times at 20°C, 40°C, and 50°C, and at different relative humidity. Then remove the chestnut shell and inner skin, measure the color ΔE value of the chestnut surface with a color difference meter, measure the water content and water-soluble sugar content, and measure the hardness with a texture analyzer. The results are shown in Table 2.

[0039] When the air humidity is 90%, a large area of mildew will appear after chestnuts are placed at room temperature for a week. Low humidity is suitable for preparing air-dried chestnuts. As the air-drying proceeds, the moisture content of the chestn...

Embodiment 3

[0045] Select chestnut variety 11, set the temperature of the constant temperature drying oven at 40°C, spread the chestnut samples on a shallow plate, and air-dry for 24 hours. Remove the chestnut shell and inner epidermis, and measure its surface color ΔEo value. After soaking with different concentrations of antioxidants for 1 hour, quickly dry the surface moisture at room temperature, put them into polyethylene packaging bags, and vacuum-pack them in a vacuum packaging machine. Take it out from the bag after 30 days, and measure the color ΔE value of the chestnut surface with a color difference meter, and the results are shown in Table 3.

[0046] As can be seen from Table 3, the anti-browning effect of ascorbic acid is the best. When air-dried chestnuts were soaked in 0.8g / L ascorbic acid solution for 24 hours, the surface browning of chestnut kernels could be effectively inhibited during storage.

[0047] Table 3 Effect of different antioxidants on the color of air-dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com