Silicon-oxygen composite negative electrode material and preparation method thereof, and lithium ion battery

A negative electrode material, silicon oxide technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as complex coating process, no breakthrough in performance improvement, high coating cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] Second aspect, such as figure 1 As shown, the application provides a method for preparing a silicon-oxygen composite negative electrode material, comprising the following steps:

[0078] S100, mixing the precursor with the pre-lithiated carbon-coated silicon-oxygen material, and performing a solid-state thermal reaction under a protective atmosphere to obtain a silicon-oxygen composite negative electrode material; the precursor includes a mixture of a phosphate ion-containing compound and a metal compound , metal phosphate, at least one of a mixture of a silicate ion compound and a metal compound, and a metal silicate; the silicon-oxygen composite negative electrode material includes a silicon-oxygen material and a composite coating layer formed on the surface of the silicon-oxygen material, The composite coating layer includes a carbon material and a lithium-containing compound, the carbon material has pores, and the lithium-containing compound is filled in the pores. ...

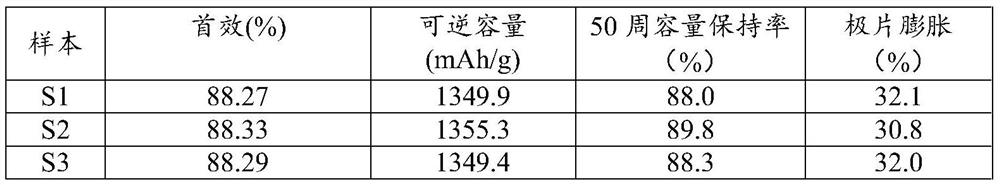

Embodiment 1

[0128] (1) react carbon-coated silicon-oxygen material SiO / C with metal lithium to obtain pre-lithiated carbon-coated silicon-oxygen material Li-SiO / C, wherein the lithium content is 10 wt%;

[0129] (2) Put V 2 o 5 Mix with phosphoric acid in a molar ratio of 1:3 to obtain a precursor;

[0130] (3) After high-speed dispersion of 5g precursor and 100g Li-SiO / C, under the protection of Ar gas, roast at 900°C for 6 hours, control the heating rate at 2°C / min, disperse and sieve after natural cooling to obtain silicon Oxygen composite anode material.

[0131] The average particle size (D 50 ) is 5.13μm, and the tap density is 0.98g / cm 3 , the specific surface area is 2.19m 2 / g, the porosity is 1.98%, and the carbon content is 5.0wt%. The composite coating layer of the silicon-oxygen composite negative electrode material is 100nm, and the lithium-containing compound is mainly Li 3 V 2 (PO 4 ) 3 , the lithium-containing compound is dispersed and filled in the pores of the...

Embodiment 2

[0133] (1) react carbon-coated silicon-oxygen material SiO / C with metal lithium to obtain pre-lithiated carbon-coated silicon-oxygen material Li-SiO / C, wherein the lithium content is 10 wt%;

[0134] (2) MgO and SiO 2 Mix according to the molar ratio of 1:1 to obtain the precursor;

[0135] (3) After high-speed dispersion of 5g precursor and 100g Li-SiO / C, under the protection of Ar gas, bake at 700°C for 6 hours, control the heating rate at 2°C / min, disperse and sieve after natural cooling to obtain silicon Oxygen composite anode material.

[0136] The average particle diameter (D 50 ) is 5.12μm, and the tap density is 0.98g / cm 3 , the specific surface area is 2.17m 2 / g, the porosity is 1.99%, and the carbon content is 5.0wt%. The composite coating layer of the silicon-oxygen composite negative electrode material is 100nm, wherein the lithium-containing compound includes Li 2 MgSiO 4 , the lithium-containing compound is dispersed and filled in the pores of the carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com