Impedance matching method and semiconductor process equipment

A technology of process equipment and impedance matching, which is applied in the direction of discharge tubes, electrical components, circuits, etc., can solve problems such as inconsistent matching time, different initial state matching process, and influence on the stability of process results, so as to reduce matching time and reduce extinction probability, the effect of small changes in chamber impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

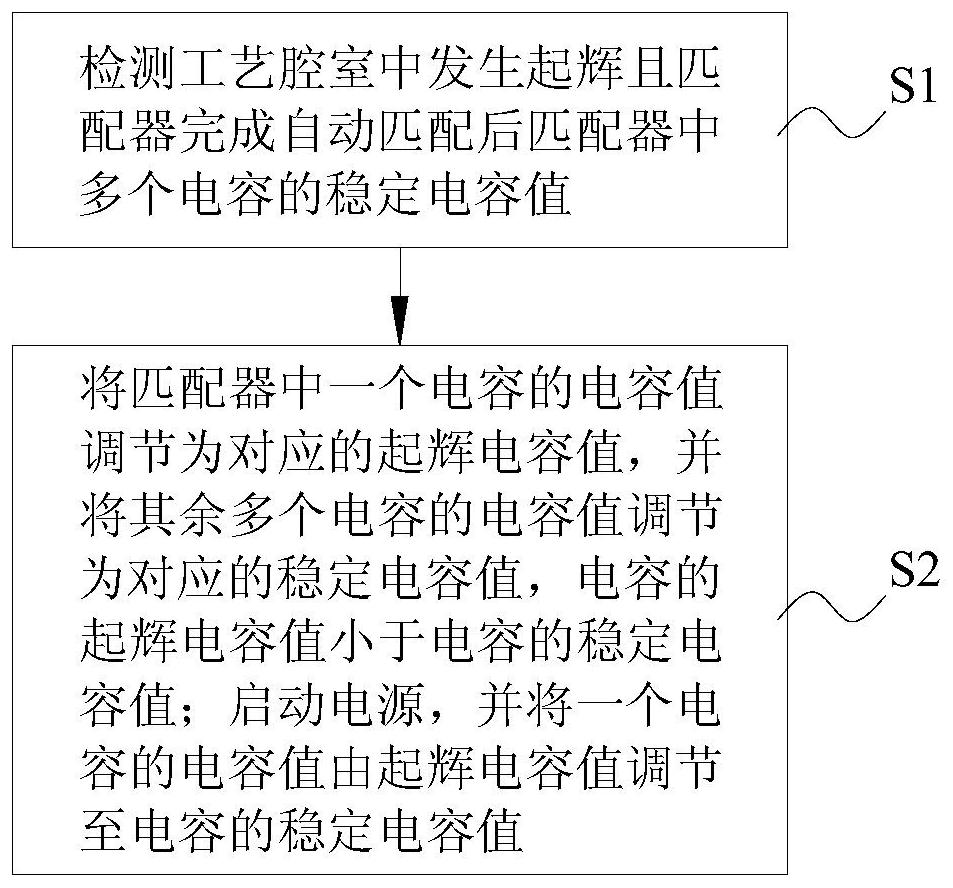

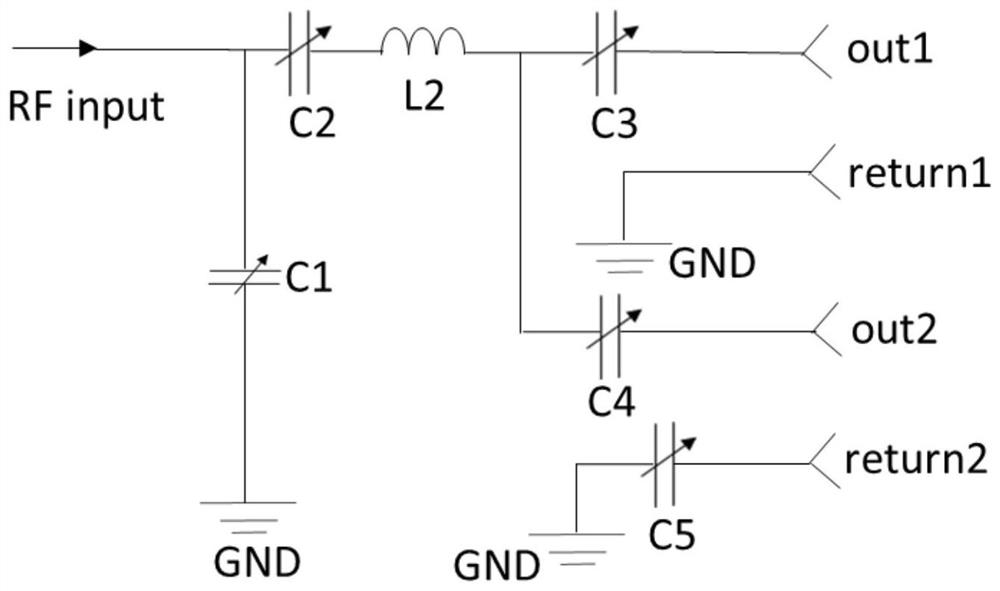

[0064] In the stage of determining the capacitance value (the first ignition), the control mode of the matcher is set to Auto preset mode, so that the matcher is in the state of automatic matching. Adjust the capacitance values of the first capacitor C1 , the second capacitor C2 and the third capacitor C3 to a preset position where any matcher can normally match. The RF power supply loads power, and the matcher automatically matches. The capacitance values a1, a2, and a3 of C1, C2, and C3 after the matcher is completely matched are recorded and saved as stable capacitance values corresponding to C1, C2, and C3, respectively.

[0065] When starting for the second time, make the matching device in a non-automatic matching state, and set the capacitance values of C1, C2, and C3 to b1, a2, and a3 respectively, where b1 is the starting capacitance value of the first capacitor C1. The RF power supply is loaded with power, and after the power is loaded in the reaction chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com