Raschel blanket digital ink-jet printing method

A raschel blanket, digital inkjet technology, applied in dyeing method, spray/jet textile material treatment, textile and paper making, etc., can solve the problems of poor penetration effect, achieve good permeability, good sizing effect and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

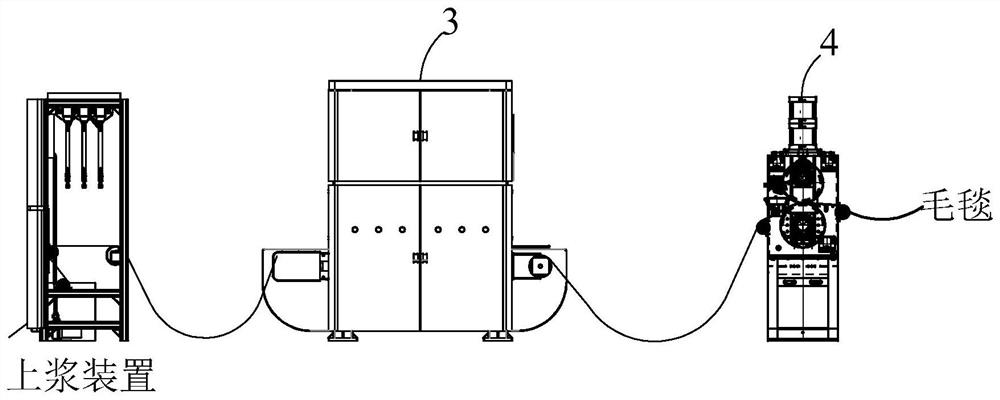

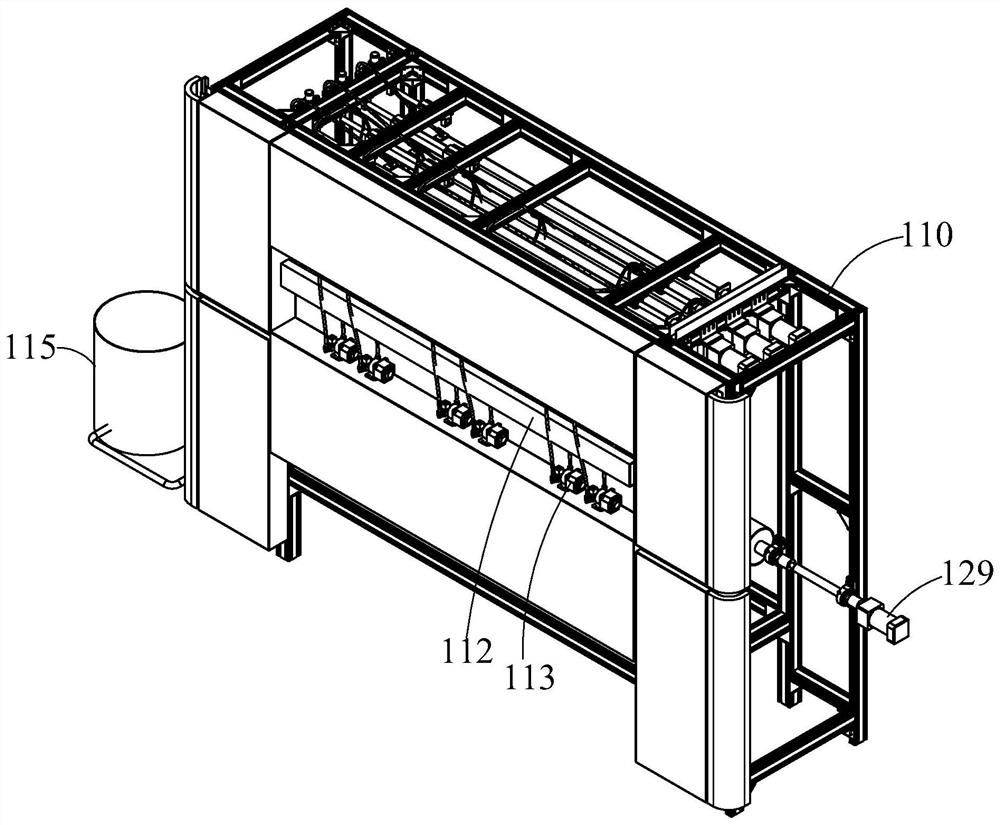

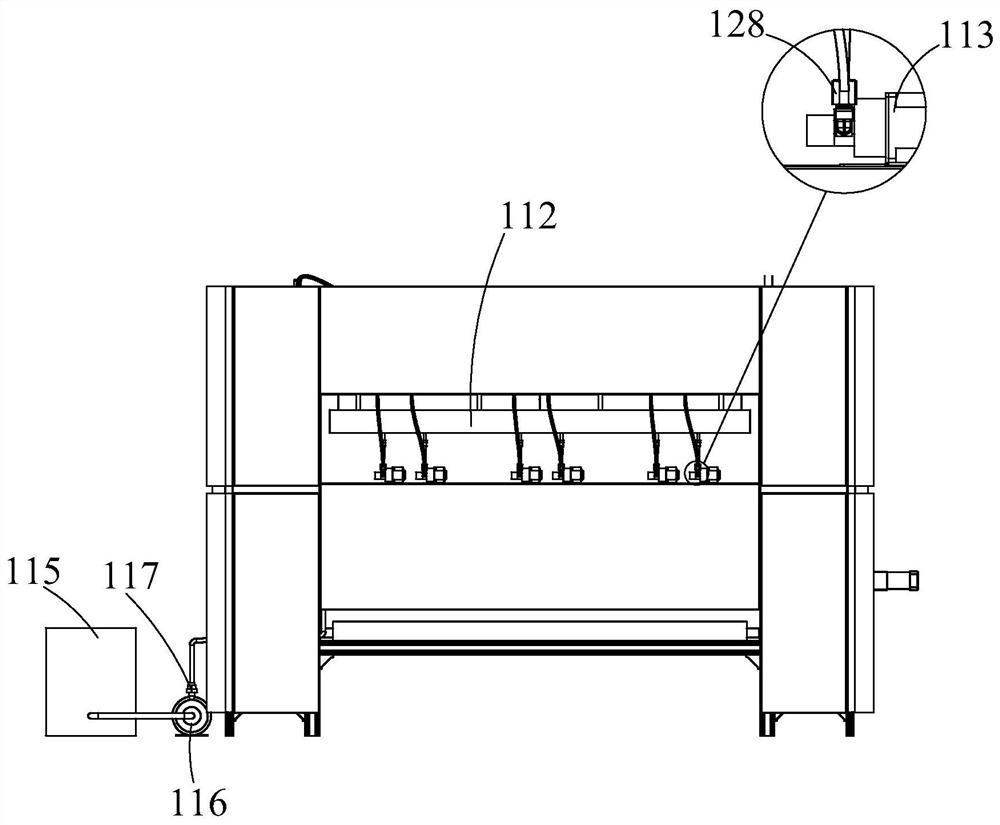

[0056] see Figure 1 to Figure 6 .

[0057] The present embodiment 1 discloses a kind of Raschel blanket digital inkjet printing method, and its steps are as follows:

[0058] Step 1: Sizing: Send the raschel blanket that has been pre-finished into the sizing device for pre-wetting treatment before sizing. The sizing device adopts a spray sizing device that can avoid overwhelming the fluff of the blanket. The sizing device is opposite to the pull Scheer blanket sprays white slurry, which is composed of synthetic thickener, water and penetrant, with a viscosity of 500-3000CPS, of which, in each liter of white slurry, thickener accounts for 10 grams, penetrant accounts for 2 grams, and the rest is water .

[0059] Step 2: The Raschel blanket that has been sized is sent to the digital inkjet printing machine for inkjet printing. The specific printing process is: transfer the designed pattern into the computer software, and send the sized blanket to the digital printing on the ...

Embodiment 2

[0083] see Figure 7 to Figure 9 .

[0084] This embodiment 2 also provides a digital inkjet printing method for Raschel blankets, the steps of which are the same as those disclosed in embodiment 1, the difference between the two is that the sizing devices used are different. The air knife spraying sizing device is adopted in the present embodiment 2, and the air knife spraying sizing device comprises a frame two 210, a cloth guide roller mechanism two 211, an air knife spraying mechanism, a raw pulp barrel two 216 and a booster pump two 217. Cloth guide roller mechanism 2 211 is installed on the frame 2 210 for guiding and conveying the Raschel blanket; the air knife spray mechanism is located above the cloth guide roller mechanism 2 211 and is used for spraying the Raschel blanket. Pour white slurry. The inlet end of the booster pump 217 is connected with the raw pulp barrel 2 216, the outlet port of the booster pump 217 is connected with the stock tank 212, and the boost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com