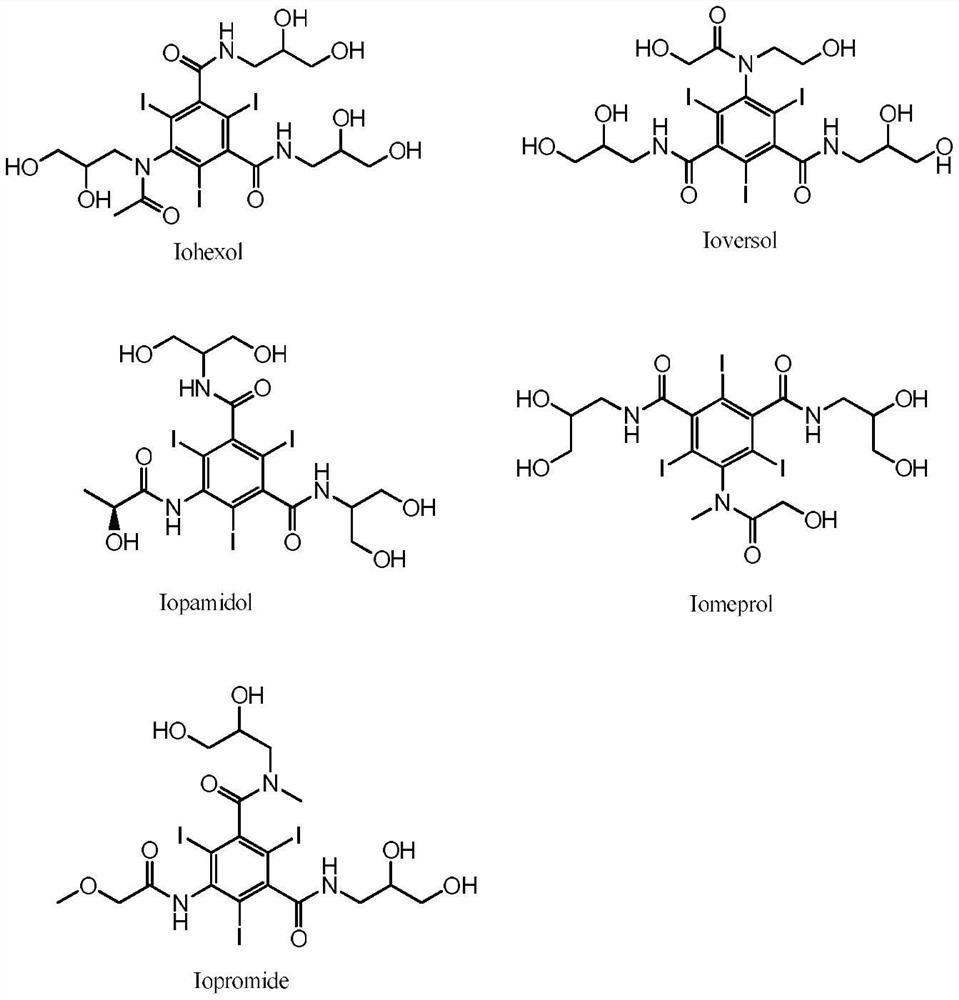

Separation and purification method of high-purity iodine contrast agent monomer

A technology of separation and purification, contrast agent, applied in the separation/purification of carboxylic acid amide, organic chemistry, etc., can solve the problem of low overall yield, and achieve the effect of good process stability, fast elution speed and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

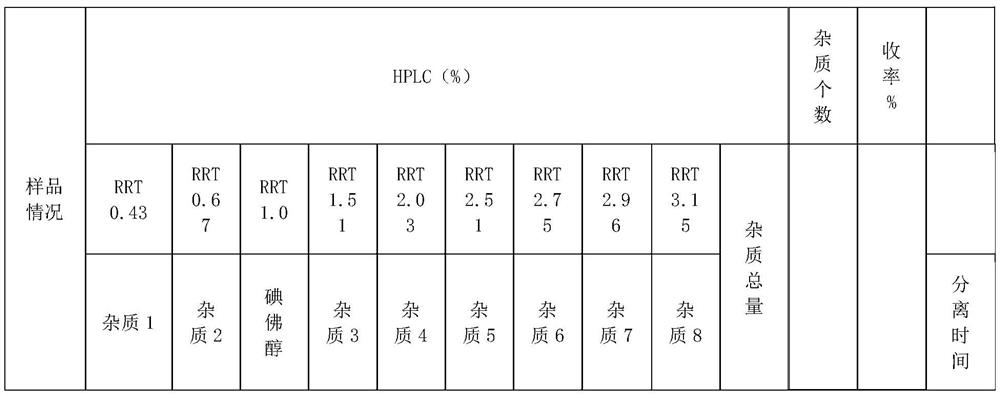

Examples

Embodiment 1

[0029] Loading solution: 37.5 ml of synthetic feed solution, the content of ioversol is 40%, and the solution is filtered with a 0.22 μm microporous membrane.

[0030] Separation and purification: The sample solution is separated and purified by a column system, and all the sample solution is injected. The column system uses octadecyl bonded silica gel filler, the column size is Φ50×650mm, the particle size is 10μm, the pore size is 10nm, the filler The mass is 300g, the solvent is water / methanol, the flow rate is 0.1bv / min; 90:10, the detection wavelength is 254nm, and the fraction is taken from the target peak to the peak and the baseline is dropped, and the collection is stopped every 3 minutes during the fraction collection process. , through the liquid phase fraction analysis, and the fractions are combined, the combined fractions are concentrated and dried to obtain the ioversol product with a purity greater than 99%.

[0031] Wherein, the synthetic feed liquid refers to...

Embodiment 2

[0033] Loading solution: 375 ml of synthetic feed solution, the content of ioversol is 40%, and the solution is filtered with a 0.22 μm microporous membrane.

[0034] Separation and purification: Separation and purification of the sample solution using a column system, all of the sample solution is injected, and the column chromatography uses an octyl silica gel column with a column size of Φ80×650mm, a particle size of 30μm, and a pore size of 12nm. The mass is 1500g, the solvent is water / ethanol (95:5), the flow rate is 0.05bv / min; the detection wavelength is 254nm, and the fraction is collected from the peak of the target peak until the peak begins to fall, and the collection is stopped every 4 minutes during the fraction collection process. According to the analysis results of the liquid phase fractions, the fractions are combined, and the combined fractions are concentrated and dried to obtain the ioversol product with a purity greater than 99%.

Embodiment 3

[0036] Loading solution: 400 ml of synthetic feed solution, the content of ioversol is 60%, and the solution is filtered with a 0.22 μm microporous membrane.

[0037] Separation and purification: Separation and purification of the sample solution using a column system, all the sample solution is injected, and the column chromatography uses a methoxysilane silica gel column with a column size of Φ80×650mm, a particle size of 40μm, and a pore size of 12nm. The mass of filler is 1500g, the solvent is 100% water, the flow rate is 0.05bv / min; the detection wavelength is 254nm, the fraction is collected from the peak of the target peak to the peak and the collection is stopped. Fraction analysis results combine the fractions, concentrate and dry the combined fractions to obtain the ioversol product with a purity greater than 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com