A stainless steel pump body forging forming process

A stainless steel pump and forming technology, applied in metal processing equipment and other directions, can solve the problems of large deformation resistance, long processing cycle, and high raw material cost, and achieve the effect of reducing cutting processing time, short cutting processing cycle, and reducing raw material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

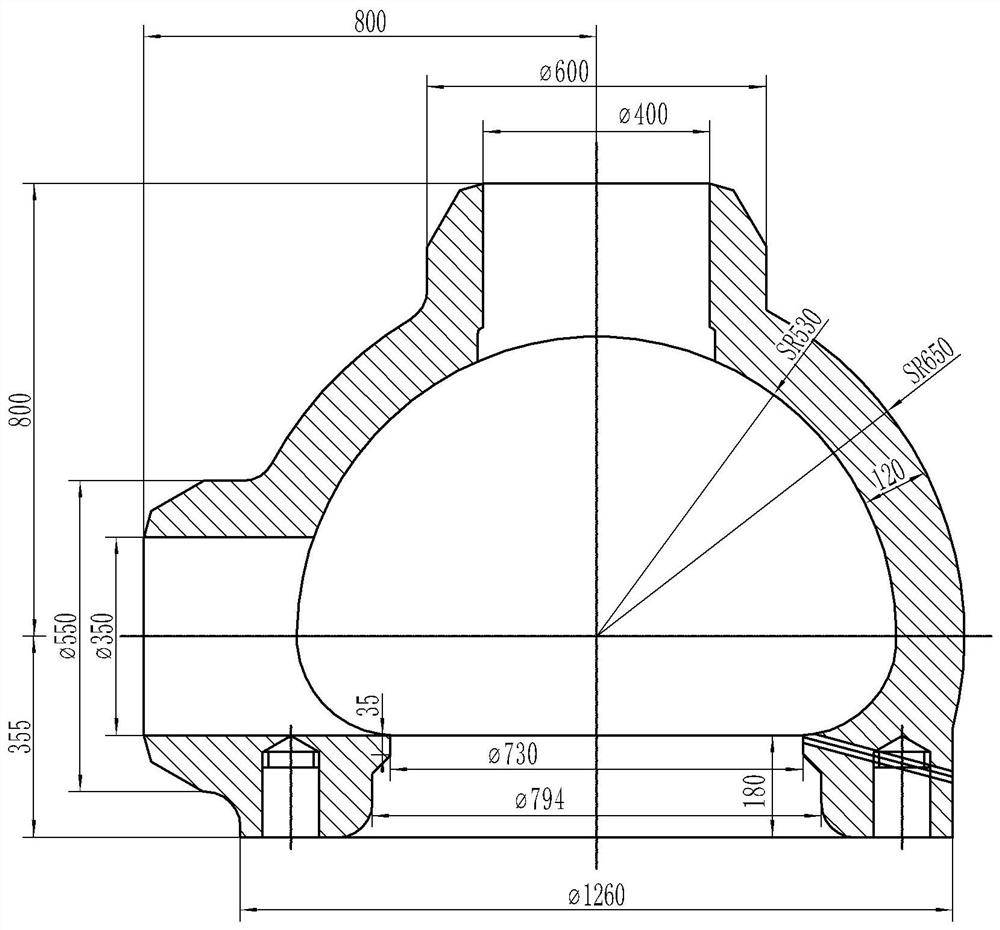

[0032] The specific embodiment is made according to the process of the present invention figure 1 The specific processing steps of step (2) near net shape forging are as follows:

[0033] a. The steel ingot is heated and uniformly penetrated, and then the wide anvil is used for upsetting and drawing to ensure the compaction and forging, the structure is dense, and the flaw detection meets the requirements;

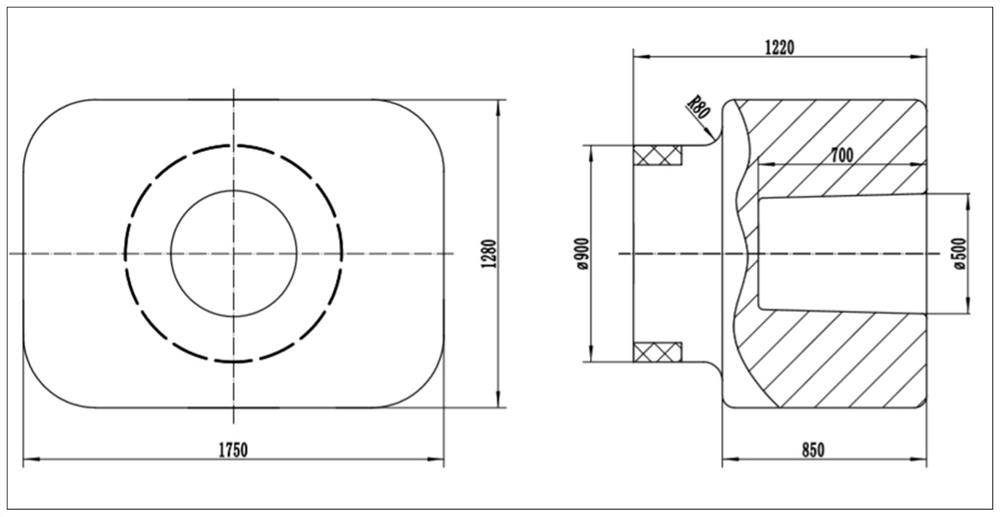

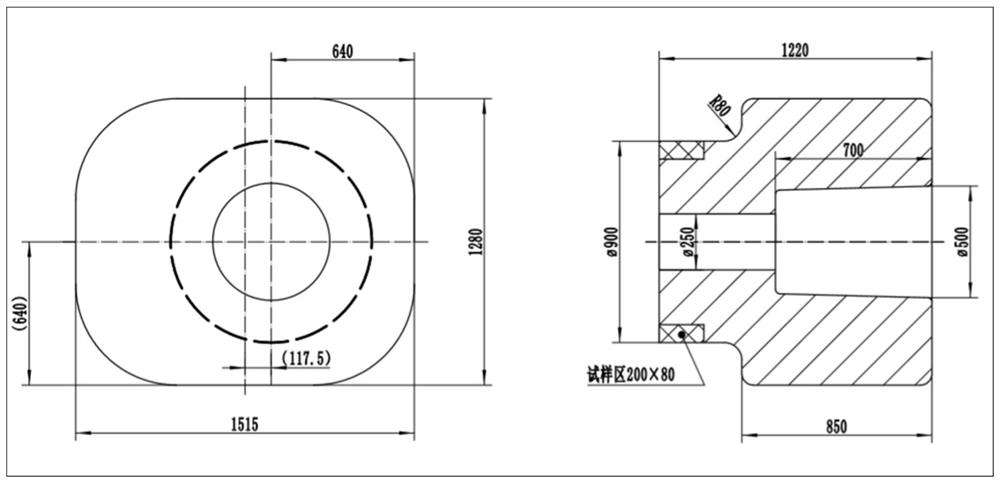

[0034] b Billet making: The first fire, the temperature is 950-1250 ℃, the riser and nozzle are cut off from the ingot; the second fire, the temperature is 900-1200 ℃, 8 times of forging and blanking are carried out by the wide anvil strong compaction process, and the forging square is 980mm. ×1200mm×1500mm;

[0035] c. Mould forming, pressing eccentric flat square: temperature 900-1200℃, pull one end and one end pulling ¢980mm×400mm, put it into the mold to form and press eccentric flat square 1350mm×1150mm×1000mm, eccentric distance 110mm;

[0036] d Final forming: The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com